Comprehensive Guide for Maintenance and Repair

Product Overview

This manual serves as a detailed guide for the maintenance and repair operations of CASE IH equipment. All procedures should be carried out exclusively by workshops authorized by CASE IH to ensure quality and safety. Adhering to the detailed instructions and using the specified tools will help prevent any damage during service operations.

Key Features

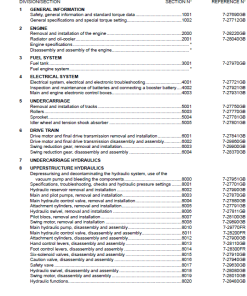

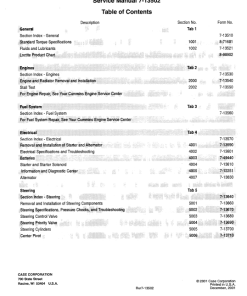

- Engine: Detailed engine maintenance procedures.

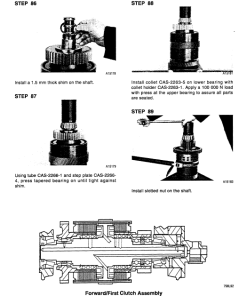

- Clutch: Clutch repair and adjustment tips.

- Transmission: Comprehensive transmission system servicing.

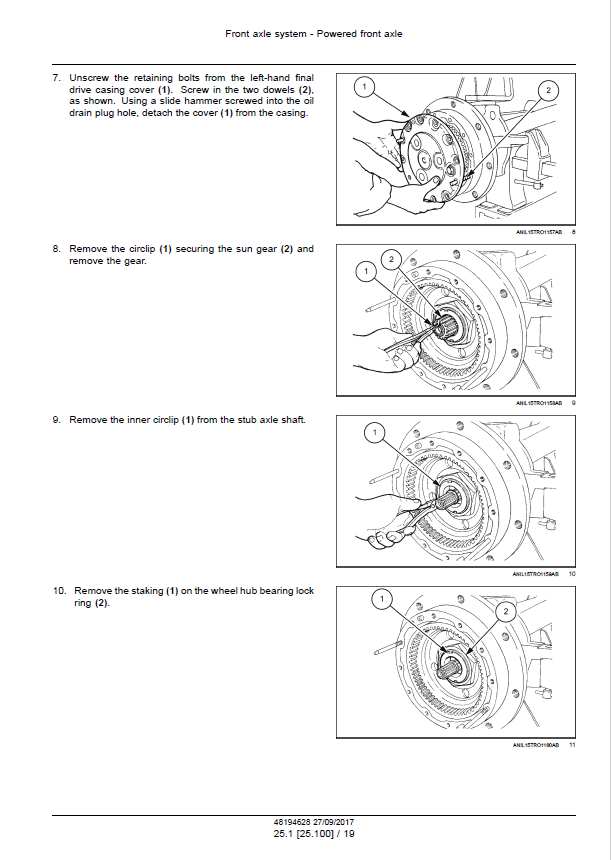

- Four Wheel Drive: Guidance on maintaining the four-wheel-drive system.

- Front and Rear Axles: Instructions for axle servicing.

- Power Take-Off: Maintenance of power take-off components.

- Brakes and Controls: Ensuring optimal brake performance and control functionality.

- Hydraulic Systems: Troubleshooting and repairing hydraulic systems.

- Steering and Wheels: Procedures for maintaining steering and wheel integrity.

- Cab Climate Control: Instructions to maintain the cab’s climate control system.

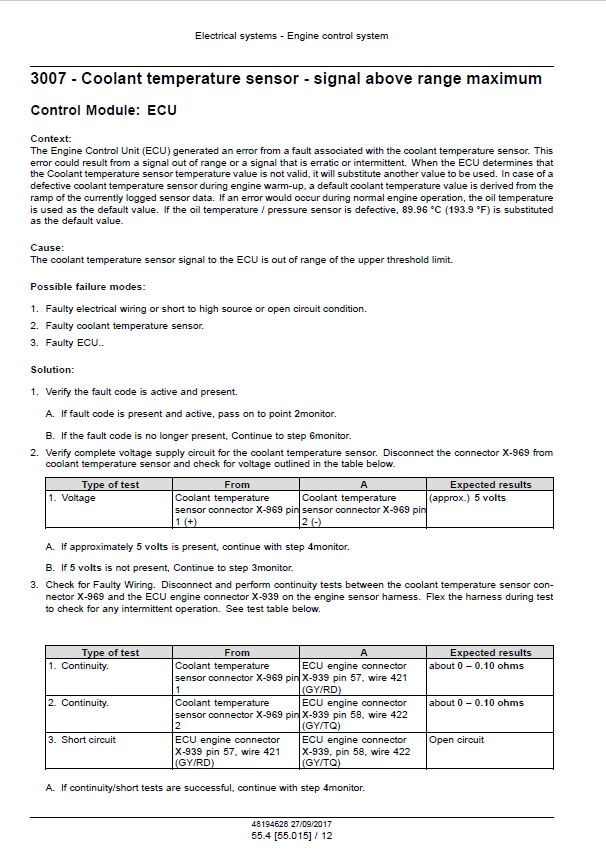

- Electrical System: Insight into servicing the equipment’s electrical components.

- Platform, Cab, Bodywork, and Decals: Care and maintenance guidance.

- Special Tools: Usage of special tools for specific repairs.

Benefits

- Authorized Excellence: All procedures are designed to be executed by CASE IH authorized professionals.

- Precision and Safety: Detailed instructions ensure safe and accurate maintenance to prevent damage.

- Comprehensive Coverage: From engine to electrical systems, every critical aspect is covered.

- Extended Equipment Lifespan: Proper maintenance leads to long-lasting equipment performance.

Usage Recommendations

- Shimming Adjustments: For each adjustment, measure shims individually with a micrometer for accuracy. Avoid measuring the entire set at once.

- Installing Rotating Shaft Seals:

- Soak the seal in the oil it will be sealing for at least 30 minutes before installation.

- Ensure the shaft is clean and free from damage.

- Align the sealing lip toward the fluid and consider the shaft rotation direction with hydrodynamic lips.

- Lubricate the sealing lip with oil and fill the gap between double lips with grease.

- Use a flat punch to press the seal into place without tapping with a hammer.

- Ensure that the seal is inserted perpendicularly to prevent damage.

- O-Rings: Lubricate O-rings before placement to prevent twisting and ensure a proper seal.

Important Notice: It is crucial to follow the detailed instructions in this manual strictly. Any deviation from the prescribed methods might result in damage, for which the individual will be responsible. Proper maintenance is key to optimal performance and longevity of the equipment.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.00

$34.00

$34.00

$34.00

$34.50

$34.00

Reviews

There are no reviews yet.