Case JX1075N, JX1095N Tractor Service Manual

$35.00

Included Manual: Comprehensive service manual with 976 pages.

Specifications:

Brand: Case

Model: JX1075N, JX1095N

Type: Tractor

Manuals: Service Manual

Publication Number: 87352295 (June 2005)

Language: English

Format: PDF

JX1075N – JX1095N Tractor Repair Manual

Product Overview

This comprehensive service manual provides detailed repair instructions and information for JX1075N and JX1095N tractors, covering various systems and components. It serves as an essential resource for technicians aiming to maintain and repair these models effectively.

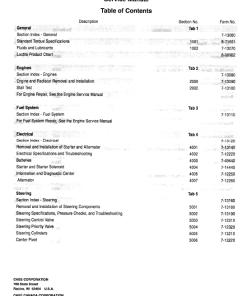

Table of Contents

- SECTION 00 – GENERAL – Page 2

- SECTION 10 – ENGINE – Page 2

- SECTION 18 – CLUTCH – Page 7

- SECTION 21 – TRANSMISSIONS – Page 9

- SECTION 23 – MFD TRANSFER BOX AND AUTO MFD – Page 10

- SECTION 25 – FRONT AXLE MECHANICAL TRANSMISSION – Page 12

- SECTION 27 – REAR AXLE MECHANICAL TRANSMISSION – Page 14

- SECTION 31 – MECHANICAL POWER TAKE-OFF – Page 15

- SECTION 33 – BRAKES – Page 16

- SECTION 35 – HYDRAULIC SYSTEM – Page 17

- SECTION 41 – STEERING – Page 19

- SECTION 44 – FRONT AXLE — 2WD – Page 20

- SECTION 50 – CAB CLIMATE CONTROL – Page 21

- SECTION 55 – ELECTRICAL SYSTEM – Page 23

- SECTION 90 – CAB, PLATFORM, AND BODYWORK – Page 29

The manual includes collated contents from each section and chapter, providing a complete repair reference (Manual# 87352289).

Manual Extract: Lock-Time the Fuel Injection Pump

n

Follow these steps to lock-time the fuel injection pump when it is removed from the tractor:

- Step 1: Fabricate a mounting plate using a 1/4-inch flat metal stock, 5 inches wide by 8 inches long. Drill a 2-inch diameter hole, 2.5 inches from one end and the side.

- Step 2: Insert the shaft end of the injection pump into the plate’s hole. Use the pump mounting holes as a template to place three marks on the plate.

- Step 3: Drill three 3/8-inch diameter holes in the plate.

- Step 4: Clamp the plate in a vise and secure the pump using three 5/16-inch x 1-inch bolts and nuts.

- Step 5: To fit the woodruff key tightly onto the pump driveshaft, drive a small mark into both sides of the key using a chisel.

- Step 6: Install the woodruff key into the pump driveshaft slot, ensuring it is correctly positioned and fits tightly.

Usage Recommendations

- Ensure staff are adequately trained to use the manual’s procedures to prevent errors during engine maintenance.

- Regularly update and refer to this manual to stay informed about any component specifics or new service protocols.

- Use appropriate safety equipment and tools when following repair instructions outlined within the manual.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.