Case TR340 Track Loader Service Manual

$37.00

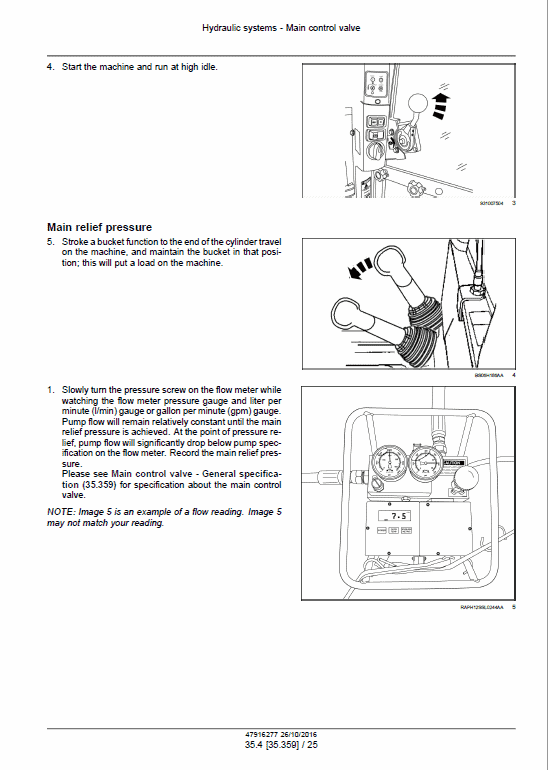

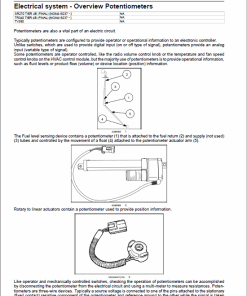

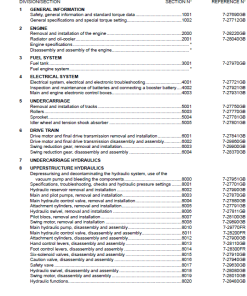

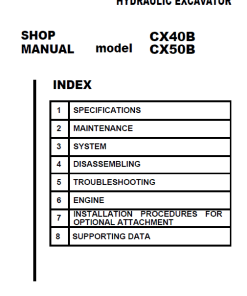

Enhance your maintenance skills with the comprehensive New Holland Alpha Series Loader Service Manual. This extensive guide spans 2330 and 2492 pages, catering to various models.

Brand: New Holland

Models Supported: SR270 / SV300 Tier 4B (Final) and TR340 / TV380 Tier 4B (Final)

Product Type: Alpha Series Skid Steer Loader and Alpha Series Compact Track Loader

Publication Details: June 2015 (Publication Number: 47685161) & October 2016 (Publication Number: 47916277)

Language: English

Format: PDF

This service manual is an essential resource for anyone needing detailed instructions on maintenance and repairs for the specified models. Access precise guidance conveniently formatted as a PDF document.

Reviews

There are no reviews yet.