Case W26 Loader Service Manual

$32.00

This comprehensive service manual for the New Holland W26 & W26 Series B Loader includes 415 and 646 pages of detailed information. Perfect for troubleshooting and repair, this manual is an essential tool for maintaining your loader.

Specifications:

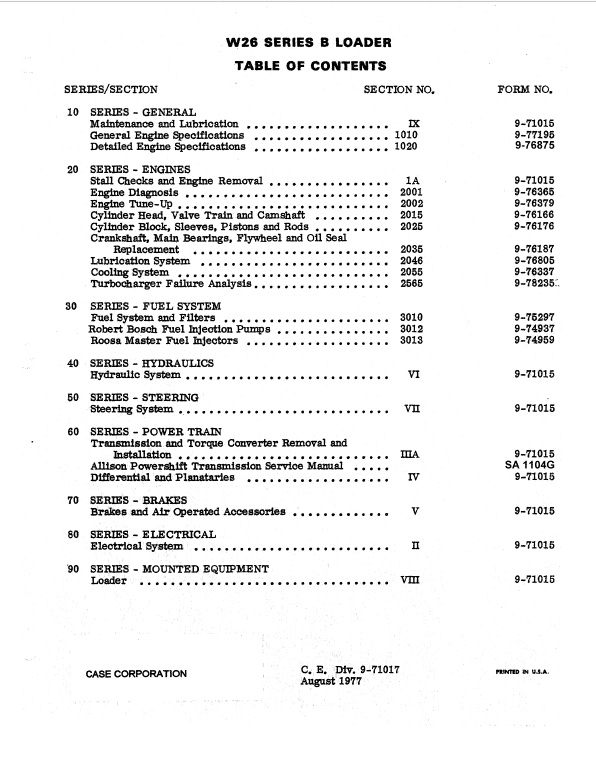

Service Manual Contents

Product Overview

This Service Manual provides comprehensive guidelines and procedures for the maintenance and repair of various components. It is an essential resource for ensuring vehicle performance and reliability.

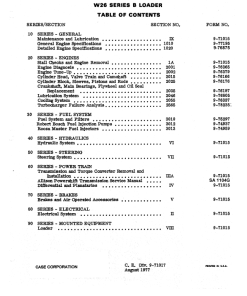

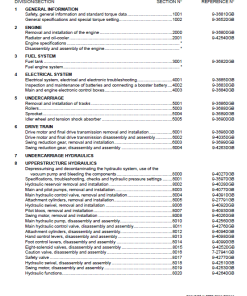

Table of Contents

- Engine

- Electrical System

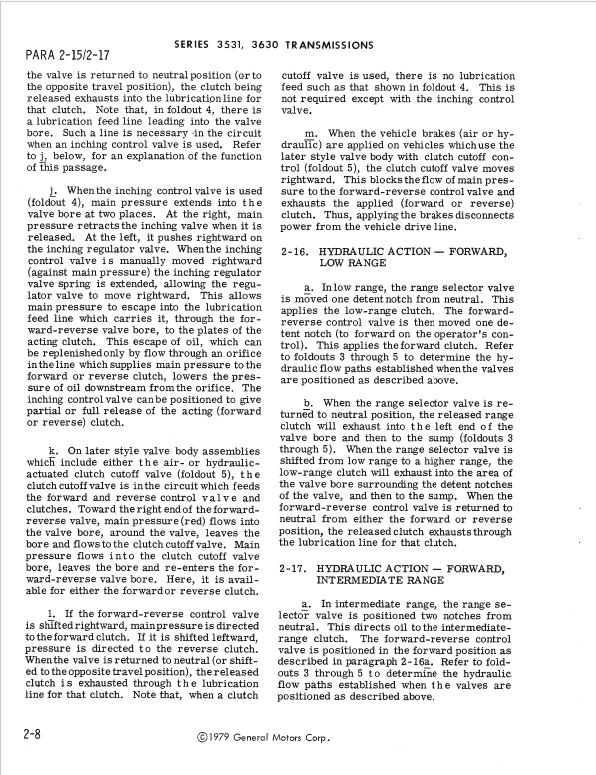

- Transmission

- Differential and Planetaries

- Brakes, Air Operated Controls, and Accessories

- Hydraulic System

- Steering

- Loader

- Maintenance Lubrication

Manual Extract: Checking Compressor Output

To ensure the compressor operates optimally before installation, perform the following tests:

- If a test rack is available, check the compressor under operating conditions. Ensure proper mounting, cooling, lubrication, and drive connection during testing.

- If no test rack is available, proceed with installation. Ensure the compressor is connected to an oil supply line with at least 15 PSI during testing, and install an oil return.

- Attach a reservoir to the discharge port, ensuring the combined volume of the reservoir and connecting line is 1300 cubic inches.

- Run the compressor at 1750 RPM. It should generate 100 PSI of air pressure in the reservoir within 30 seconds or less

Installation Instructions

- Carefully install the compressor straight into the rear of the engine, ensuring the coupling parts are undamaged.

- Secure the compressor using bolts and lock washers.

- Refer to Figure 14 for guidance. Connect the intake line, exhaust line, and governor air line.

- Connect the three oil lines to the engine as specified.

Only logged in customers who have purchased this product may leave a review.

Related products

$35.00

$34.00

$34.00

$32.00

$34.00

$34.00

$33.00

Reviews

There are no reviews yet.