Maintenance Guide for Air Intake System

Product Overview

The air intake system is a critical component of your machinery, ensuring optimal engine performance by filtering debris and contaminants. Regular maintenance is essential to prevent engine damage and ensure longevity.

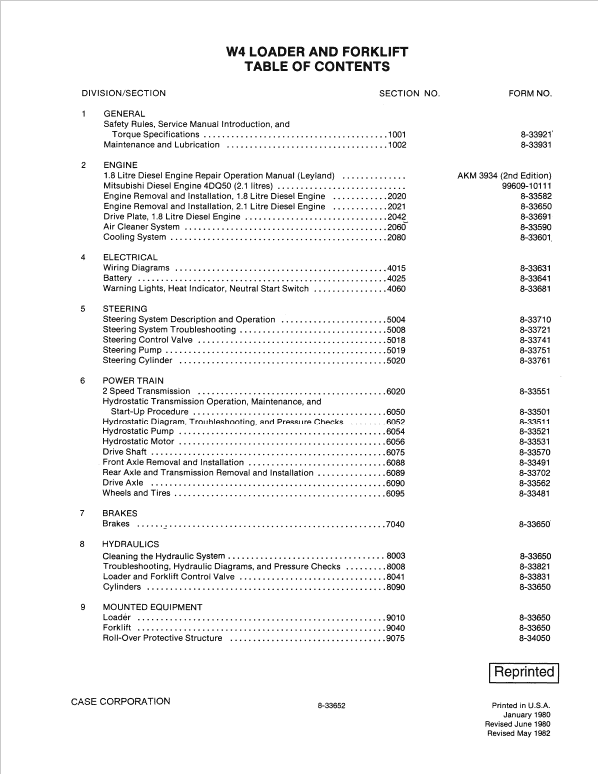

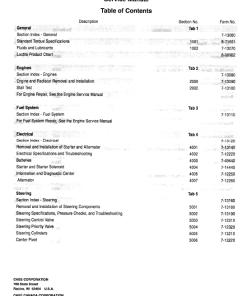

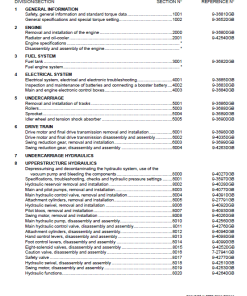

Table of Contents

- General

- Engine

- Electrical

- Steering

- Power Train

- Brakes

- Hydraulics

- Mounted Equipment

Key Features

- Efficient removal of contaminants from the air intake system

- Comprehensive cleaning process including air cleaner body and hoses

- Use of specialized cleaning solutions for optimal results

Benefits

- Prevents engine damage from dirt and debris

- Prolongs the life of engine components

- Maintains optimal engine performance

Usage Recommendations

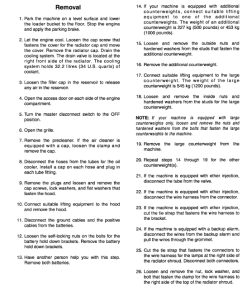

- When the air intake system becomes dirty or contaminated, clean the air cleaner body and all hoses.

- For heavy oil or soot contamination, use a solution made with Case Filter Element Cleaner (part number A4091 O) by mixing 57 grams (two ounces) of cleaner with 3.8 liters (one gallon) of water, at 38 u00b0 to 66 u00b0 C (100 u00b0 to 150 u00b0 F).

- If dirt is significantly heavy, opt for a solution of Oakite 202 with 50% water.

- Immerse parts in the solution for 30 minutes. Agitate them for approximately two additional minutes.

- Rinse the parts with clean water until clear and dry them thoroughly.

- Inspect all hoses and parts for cracks, wear, and leaks in the air intake system, including the safety element. Replace as necessary.

- Important: Ensure all hoses are installed airtight to prevent engine damage over time.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.00

$35.00

$34.00

$33.00

Reviews

There are no reviews yet.