CAT DP100N1, DP120N1, DP135N1, DP150N1, DP160N1 Forklift Service Manual

$38.00

Comprehensive CAT Service Manual Collection

Explore our extensive collection of CAT service manuals, meticulously detailed for optimal maintenance and operation guidance. This collection includes:

- CAT Service Manual: 686 pages of in-depth information.

- Operation and Maintenance Manual: 204 pages of essential maintenance tips.

- 1204E Diesel Engine Manual: An expansive 880-page guide.

This manual set is specifically designed for the Lift Truck Forklift Models: DP100N1, DP120N1, DP135N1, DP150N1, and DP160N1.

Publication Number: 99799-60100

Language: English

Format: PDF

Caterpillar CAT DP Series Lift Truck Manual

Product Overview

Explore the comprehensive guide for Caterpillar Lift Truck models DP100N1, DP120N1, DP135N1, DP150N1, DP160N1. This manual, published as document number 99799-60100 and available in English, offers a detailed framework for maintenance and operation. In PDF format, it includes:

- Forklift Service Manual: 686 Pages

- Operation and Maintenance Manual: 204 Pages

- 1204E Diesel Engine Manual: 880 Pages

Key Features

- Extensive information on lift truck components and systems

- Detailed diagrams and circuit schematics

- Comprehensive sections on maintenance and operational procedures

Benefits

- Ensures safe and efficient operation of lift trucks

- Provides step-by-step guidance for repairs and maintenance

- Enhances understanding of complex component interactions

Usage Recommendations

- Read thoroughly before operating or servicing the lift trucks to avoid injury or damage.

- Use proper lifting techniques for handling heavy components as outlined in the manual.

- Apply the appropriate tools and new seals for assembly and maintenance work.

- Assure all components are correctly aligned and secured during installation.

Manual Table of Contents

- General Information

- Cooling System

- Electrical System

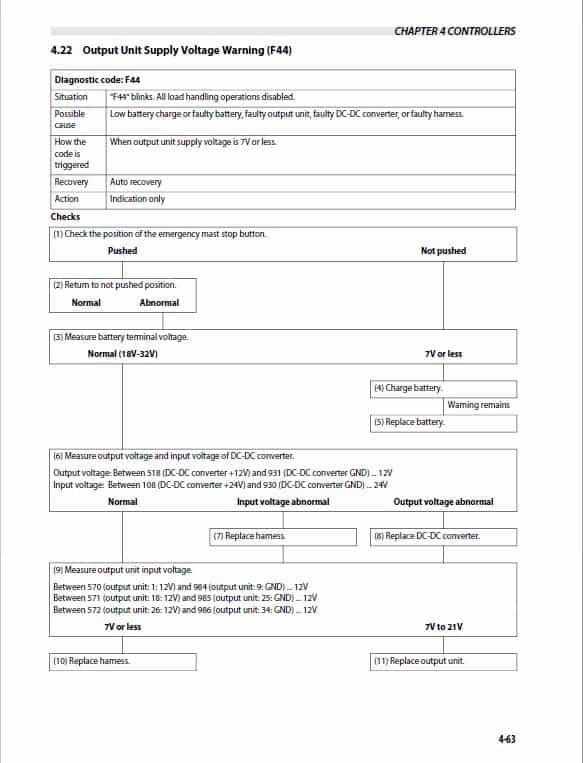

- Controllers

- Power Train

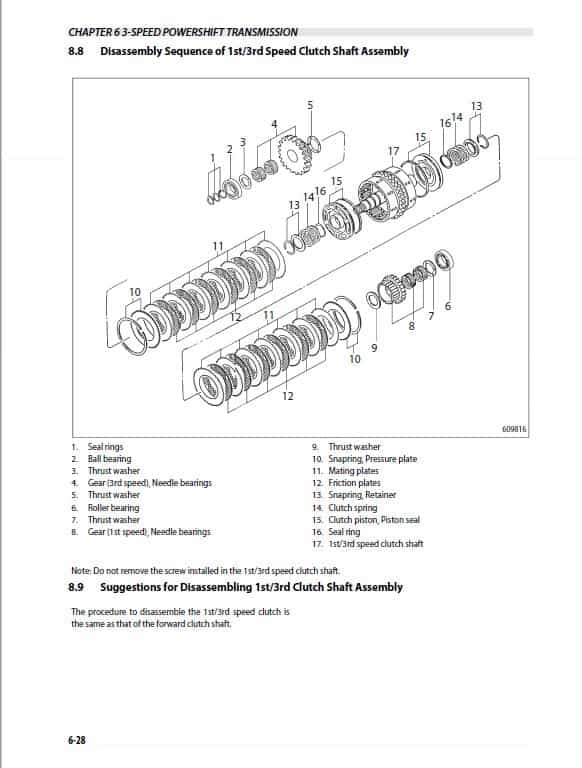

- 3-Speed Powershift Transmissions

- Front Axle and Reduction Differential

- Rear Axle

- Brake System

- Steering System

- Hydraulic System

- Masts and Forks

- Side Shifter

- Fork Positioner

- Service Data

- How to Read Circuit Diagrams

- Circuit Diagram

Before disassembling any component, it is crucial to understand the system’s operation. Refer to the weights of parts to ensure safe handling. Follow specified procedures in the manual to prevent accidents or potential hazards.

Assembly Instructions:

- For PTO drive gear, press the ball bearing and tap the gear onto the stator shaft.

- Replace oil seals using the specified tool before fitting them into the torque converter housing.

- Assemble the oil pump components, ensuring all parts are lubricated with ATF before installation.

- Secure O-rings on all relevant parts for effective sealing.

- Ensure precise alignment when fitting the pump drive gear into the transmission case.

- Use proper tools to prevent movement when installing ball bearings.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.