Caterpillar CAT EC15N, EC18N, EC20N Lift Truck Manual

Product Overview

The Caterpillar CAT EC15N, EC18N, EC20N Lift Truck Manual is an essential resource for maintaining and servicing your lift truck models EC15N, EC18N, and EC20N. This comprehensive guide is published under the reference number 99759-6K110, and it offers in-depth information in English, presented in a convenient PDF format.

This service manual includes 213 pages dedicated to the forklift specifications and operations and an additional 199 pages focusing on the controller details.

For more information on these models, please visit the Lift Truck Forklift Model page.

Key Features

- Publication Number: 99759-6K110

- Language: English

- Format: PDF

- Detailed Forklift Service Manual – 213 Pages

- Comprehensive Controller Manual – 199 Pages

- Thorough analysis and troubleshooting sections

Table of Contents

- General Information

- Front Axle and Reduction Differential

- Transfer Assembly

- Rear Axle

- Brake System

- Steering System

- Hydraulic System

- Masts and Forks

- Troubleshooting

- Maintenance Service Data

Benefits

- Ensures proper maintenance and operation of lift trucks

- Reduces downtime with accessible troubleshooting information

- Extends the lifespan of your equipment

Usage Recommendations

- Regularly inspect components such as reduction gears and differentials for wear or damage.

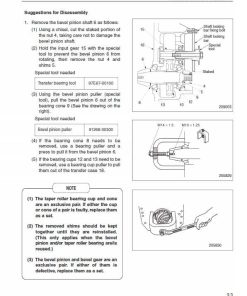

- Use the manual to guide maintenance tasks including component disassembly and reassembly.

- Follow specific guidelines for troubleshooting and servicing various systems like brakes and hydraulics.

- Pay particular attention to precision fit measurements for components like differential pinions and gears.

Inspection Details

For effective maintenance, a thorough inspection after disassembly is essential.

- Reduction Gear: Check the teeth for wear, pitting, flaking, or chipping. Minor flaws can be fixed with an oil stone or hand grinder. If replacement is necessary, both the gear and pinion, which are a matched set, should be replaced.

- Differential:

- Inspect the differential cases for any damage, focusing on the seat for the side bearing inner race.

- Check the sliding surfaces of the thrust washers and gears for signs of wear or damage.

- Examine the differential pinions and bevel gears for pitting, chipping, or galling.

- Verify the fit of each pinion on the spider, ensuring precision within the specified range of 0.02 to 0.07 (0.0008 to 0.0028).

Fit Specifications:

A: 0.02 to 0.07 (0.0008 to 0.0028) u2022 B: 0.35 (0.0138)

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.