CAT EP16KT, EP18KT, EP20KT Forklift Lift Truck Service Manual

$35.00

CAT EP16KT, EP18KT, EP20KT Forklift Service Manual

Enhance your knowledge on the CAT EP16KT, EP18KT, and EP20KT Forklifts with this comprehensive Service Manual. It includes 293 pages of detailed instructions and guidelines. Additionally, a Controller Manual featuring 254 pages is provided.

Publication: 99719-6A100

Language: English

Format: PDF

Caterpillar CAT EP16KT, EP18KT, EP20KT Lift Truck Manual

Product Overview

The Caterpillar CAT EP16KT, EP18KT, EP20KT Lift Truck Manual provides comprehensive guidance for owners and technicians working with these forklift models. This informative service manual and controller manual are essential resources for maintaining and optimizing the performance of your Caterpillar lift trucks.

Publication Number: 99719-6A100

Language: English

Format: PDF

Service Manual Length: 293 Pages

Controller Manual Length: 254 Pages

Key Features

- General Information

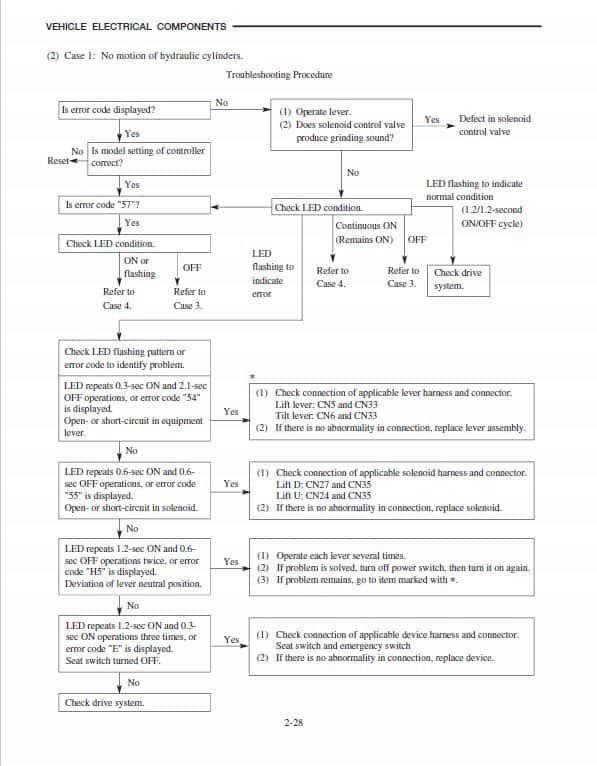

- Vehicle Electrical Components

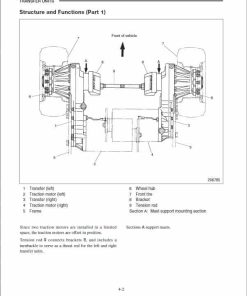

- Power Train

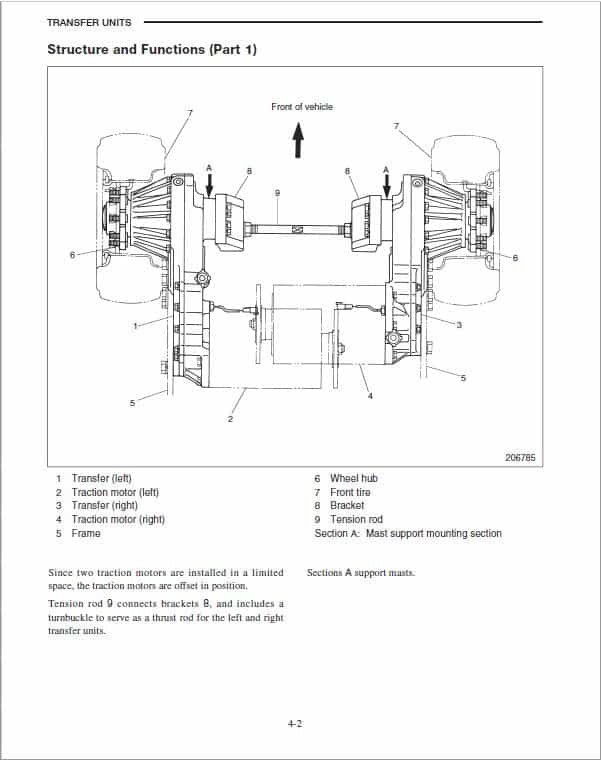

- Transfer Units

- Rear Axle

- Brake System

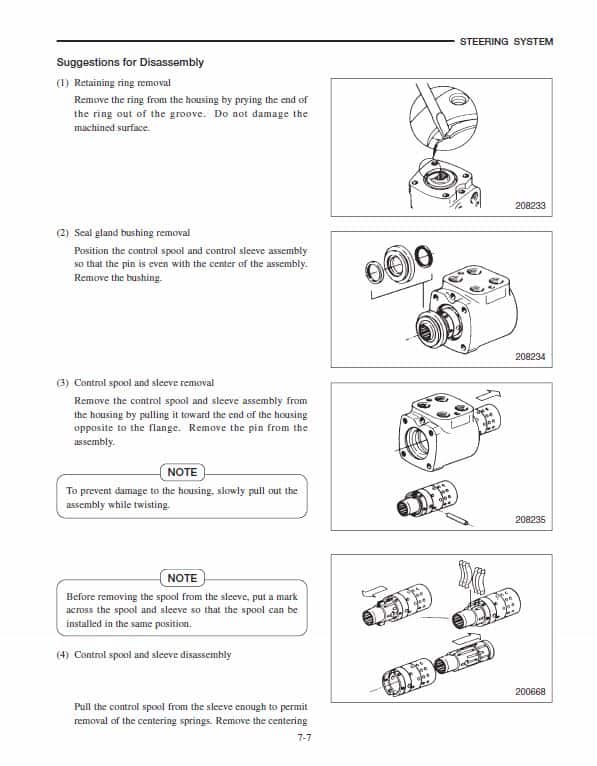

- Steering System

- Hydraulic System

- Masts and Forks

- Service Data

- Options

Benefits

- Detailed information to enhance troubleshooting and maintenance processes.

- Step-by-step disassembly, inspection, and reassembly instructions for accurate repairs.

- Focus on safety and efficiency with specific chapters on brake systems and hydraulic components.

Usage Recommendations

- Regularly inspect and maintain the brake system to prevent rust, corrosion, and ensure safety. Check all cylinder components and replace any worn parts annually.

- Follow disassembly and reassembly instructions carefully, utilizing recommended cleaning solutions and lubrication for best results.

- Utilize the manual during troubleshooting and repairs to reduce downtime and improve lift truck reliability.

Brake System Inspection and Reassembly

Inspection after Disassembly:

- Cylinder Body: Check for rust, corrosion, or scuffing, and ensure ports are unclogged. Inspect joint bolts and boots for damage.

- Piston: Examine for damage; replace if necessary. If clearance between piston and cylinder exceeds the limit, replace both.

- Return Spring: Replace annually to maintain system reliability.

- Primary Cup, Secondary Cup, and Valve: Inspect rubber components for damage or swelling; replace annually.

Reassembly:

Follow the reverse of the disassembly sequence. Clean all metal components with a volatile solution and dry with compressed air. Apply a thin layer of brake rubber grease or fluid on the cylinderu2019s inner surface and piston cup for optimal functionality.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.