Challenger 1038, 1042, 1046, 1050 Tractor Service Manual

$40.00

Discover the comprehensive Challenger 1000 Series Tractor Workshop Manual, covering models 1038, 1042, 1046, and 1050. This detailed guide spans 1489 pages, providing in-depth insights and instructions.

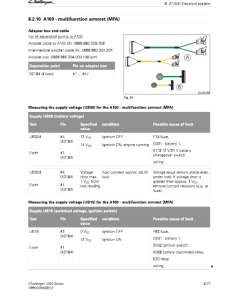

Included is the specialized Electrical Diagrams and Schematics for the North America Version, which consists of 166 pages, ensuring you have all the technical information you need.

Additionally, access the Spicer 990 Axle Service Manual, spread across 188 pages, offering expert guidance on axle maintenance and servicing.

Challenger 1000 Series Tractor Repair Workshop Manual

Product Overview

This comprehensive repair workshop manual covers the AGCO Challenger 1000 Series Tractors, including models 1038, 1042, 1046, and 1050. Specifically designed for professionals and enthusiasts, this manual is available in PDF format and consists of a whopping 1489 pages with detailed instructions and diagrams. Additional resources include 166 pages of electrical diagrams and schematics for the North America Version and a separate 188-page Spicer 990 Axle Service Manual.

Publication Details:

Book Number: X990005558012

Language: English

Publication Date: May 2018

Key Features

- General Instructions

- Engine, Fuel, and Exhaust System

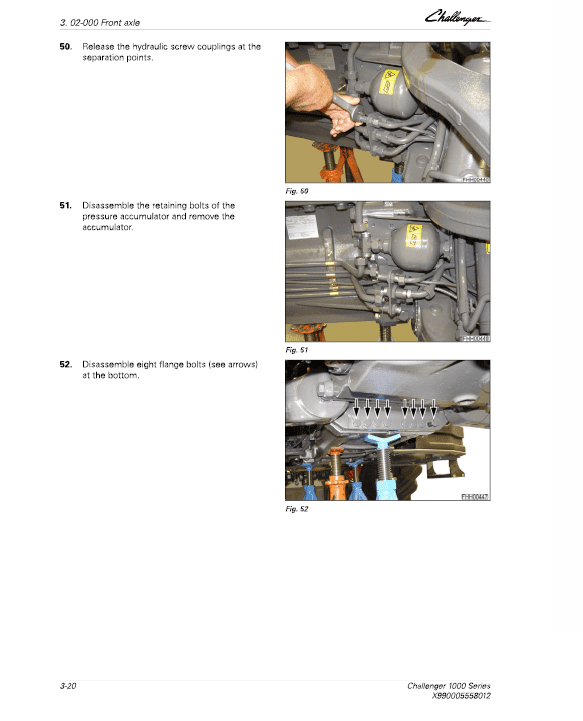

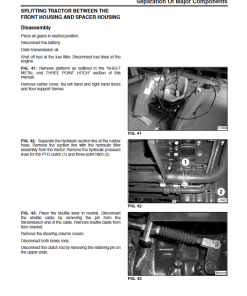

- Front Axle and Steering System

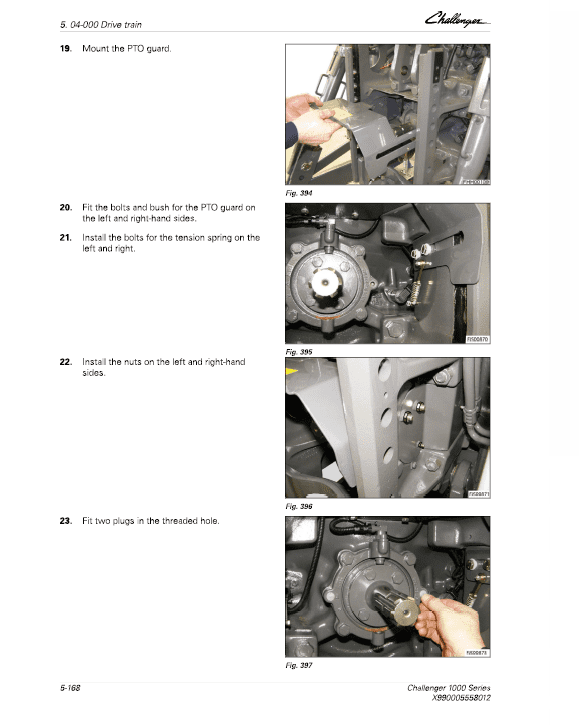

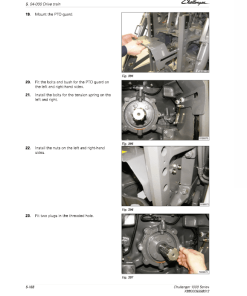

- Drive Train Functionality

- Compressed Air System Maintenance

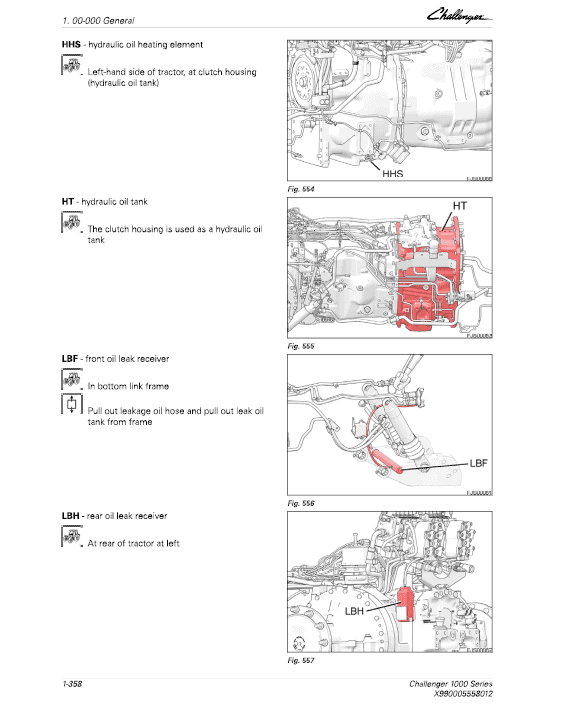

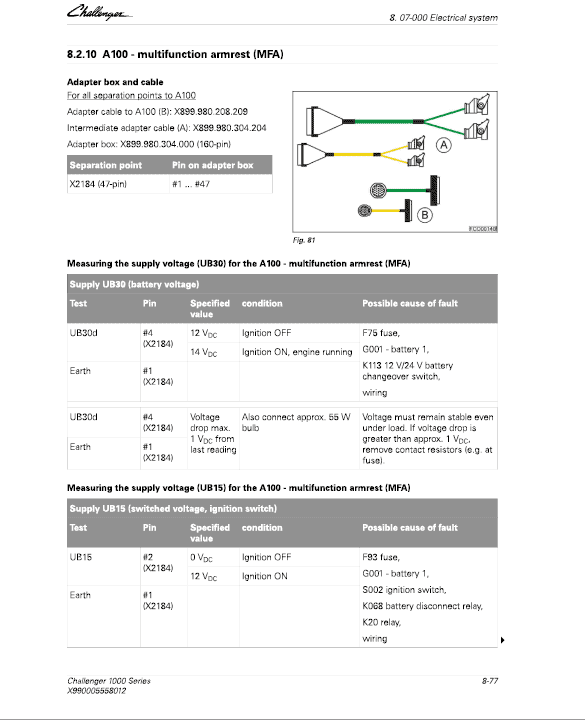

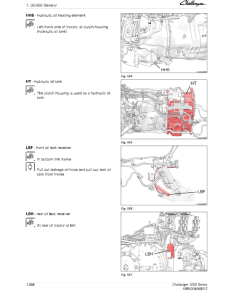

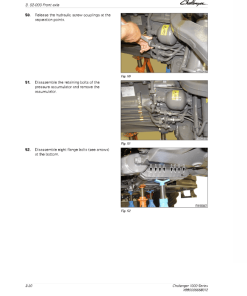

- Hydraulic and Electrical Systems

- Cab Maintenance

- Front and Rear Power Lifts

Benefits

- Comprehensive guide with detailed illustrations and instructions for each component.

- Facilitates troubleshooting and repairing of complex systems efficiently.

- Enhances safety through detailed guidelines and precautions.

Usage Recommendations

- Always store, transport, and dispose of renewed parts, fuel, and lubricants according to regulations.

- Avoid running the engine in enclosed spaces without proper exhaust gas extraction.

- Perform engine maintenance and repairs only when the engine is off and secured.

- Regularly inspect high-pressure fuel systems for leaks; use protective gear, such as goggles, during checks.

- Avoid operating near sparks, flames, or while smoking to prevent accidents.

Safety Precautions for Engine Work

To ensure safety while working on the engine:

- Switch off and secure the engine before commencing any cleaning, maintenance, or repair work.

- Never operate with deformed injection pipes or high-pressure lines; replace any damaged parts immediately.

- Avoid loosening injection pipes while the engine is running.

- Perform visual inspections for high-pressure components before engine checks, wearing suitable protective clothing like goggles.

- Stay clear of potential fuel spray zones to prevent injuries.

- Do not disconnect injectors while the engine is operational.

Following these precautions will minimize risks and ensure a safer working environment during maintenance and repairs.

Only logged in customers who have purchased this product may leave a review.

Related products

Challenger

Challenger

Reviews

There are no reviews yet.