Challenger MT455D, MT465D, MT475D Tractor Service Manual

$40.00

Explore comprehensive service guidance with our Challenger MT455D, MT465D, MT475D Tractor Workshop Manual. This extensive resource includes:

Challenger MT455D, MT465D, MT475D Tractor Repair Workshop Manual

Product Overview

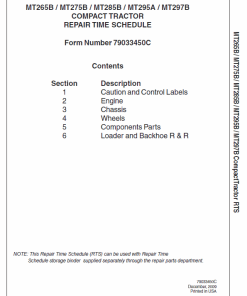

The AGCO Challenger MT4000D Series Tractor Repair Workshop Manual is an indispensable resource for understanding and maintaining your Challenger tractor models MT455D, MT465D, and MT475D. This comprehensive manual is provided in PDF format with a publication number 7060336M1, published in English in April 2013.

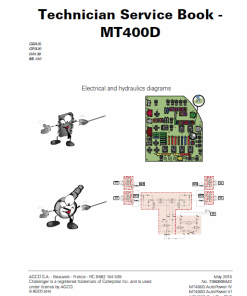

The manual includes a vast array of technical information across 3627 pages, segmented into key documents such as the Technician Service Book (683 pages), Parts Catalog (359 pages), and the AGCO Sisu Engine Manual (116 pages).

Key Features

- Comprehensive coverage for Challenger MT455D, MT465D, and MT475D models.

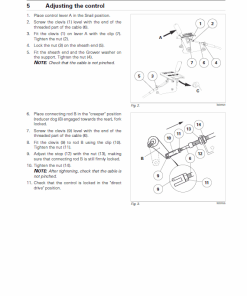

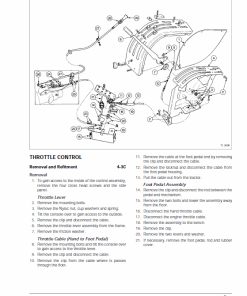

- Detailed workshop procedures, diagrams, and instructions.

- Technician Service Book included for in-depth technical service insights.

- Parts Catalog assists with quick identification and ordering of components.

- Guidance on the AGCO Sisu Engine Manual for engine-specific maintenance.

Benefits

- Enhance tractor performance and longevity with precise maintenance guidelines.

- Access detailed troubleshooting and repair procedures.

- Streamline parts identification and procurement.

- Save time with organized, step-by-step instructions.

Usage Recommendations

- Ideal for trained technicians and experienced DIY users.

- Perfect for routine maintenance, troubleshooting, and repairs.

- Keep this manual on hand in your workshop for quick reference.

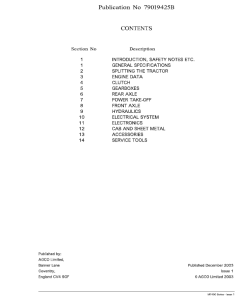

Challenger MT4000D Series Manual Table of Contents

- Introduction

- Separating of assemblies

- Engine

- Clutch

- Gearbox

- Rear Axle

- Power take off

- Front Axle

- Electronics

- Accessories

- Service tools

Extract: High-Pressure System and High Flow Rate

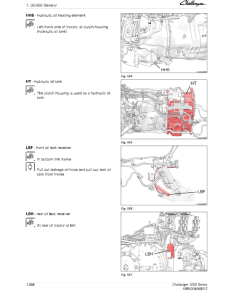

The high-pressure system with a high flow rate is supported by a 19 cmu00b3 (1.16 inu00b3) pump attached to the internal face of the right-hand cover plate. The pump prioritizes the trailer brake spool valve, followed by the front axle suspension and the high-pressure braking system via respective priority valves. Additional features control auxiliary spool valves and the linkage valve, with a 200 bar (2901 psi) safety valve ensuring system protection.

Oil not utilized by priority systems is directed towards auxiliary spool valves located at the back of the linkage cover plate. Excess flow returns to the pump’s inlet manifold, bypassing the 150-micron filter. For tractors with a suspended front axle or high-pressure braking, a priority unit controls the flow limiting and supplies power as needed.

Only logged in customers who have purchased this product may leave a review.

Related products

Challenger

Reviews

There are no reviews yet.