Challenger MT485E, MT495E Tractor Service Manual

$40.00

This comprehensive workshop manual for the Challenger MT485E and MT495E tractors consists of 1,376 pages, providing detailed guidance for maintenance and repair.

The Technician Service Book for the MT400E includes 646 pages, offering schematics and electronic servicing information crucial for technicians.

The Spicer Dana Axle Service Manual provides complete servicing information over two sections, each 176 pages, covering models 740 and 735.

Challenger MT485E, MT495E Tractor Repair Workshop Manual

Product Overview

This comprehensive workshop manual is designed for the AGCO Challenger 1000 Series Tractors, specifically the MT485E and MT495E models. It provides detailed instructions and technical guidance for repair and maintenance. Available in PDF format, this manual (Book Number: ACT0026660) is written in English and was issued in May 2016.

Download the AGCO Challenger 1000 Series Tractor Manual

Contents

The Challenger MT485E, MT495E Tractor Workshop Manual includes:

- 1376 Pages of comprehensive guidance

- Technician Service Book MT400E, focusing on schematics and electronics, with 646 pages

- Spicer Dana 740, 735 Axle Service Manual with a total of 352 pages

Challenger MT400E Series Manual Table of Contents

- Introduction

- Separation of Assemblies

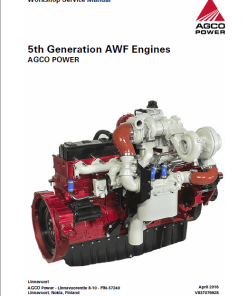

- Engine

- Clutch

- Gearbox

- Rear Axle

- Power Take-off

- Front Axle

- Hydraulics

- Electricity

- Electronics

- Operator Environment

- Accessories

- Service Tools

Key Features

- In-depth coverage of all major components and systems

- Step-by-step procedures for troubleshooting and repair

- Comprehensive schematics and illustrations

Benefits

- Helps technicians perform accurate repairs efficiently

- Ensures longevity and optimal performance of your tractors

- Reduces downtime with clear and organized instructions

Usage Recommendations

- Always follow the detailed disassembly and reassembly procedures provided.

- Use original replacement parts to maintain reliability.

- Conduct regular maintenance checks using the manual to prevent major breakdowns.

Extract: Challenger Tractor Manual MT485E, MT495E

Disassembling and Reassembling a Lift Ram

On tractors with the enhanced capacity linkage on the GPA20 + rear axle, different lift rams and strokes are featured compared to the standard configurations.

Disassembly Procedure

- Start the engine; use the electronic control to lower the hitch arms completely.

- Disconnect the supply hose from the union (1) and remove the ram (6).

- Remove the elbow or straight union (1), fitted with its “O” ring, and proceed to disassemble the rod and seals as specified.

- Replace the rod and seals, where necessary, to avoid any damage during reassembly.

Reassembly Procedure

- Thoroughly clean all components except seals, then use compressed air to dry.

- Use fresh transmission oil for lubrication during assembly.

- Install new snap rings and seals, ensuring correct fitting to avoid damage.

- Carefully align and insert the rod into the ram body.

Only logged in customers who have purchased this product may leave a review.

Related products

Challenger

Reviews

There are no reviews yet.