Challenger MT515E, MT525E, MT535E, MT545E Tractor Workshop Manual

$40.00

Models Covered: MT515E, MT525E, MT535E, MT545E

Enhance your maintenance skills with the comprehensive Challenger MT500E Series Tractor Workshop Manual. This detailed guide spans 3,455 pages, providing essential information for proper tractor servicing.

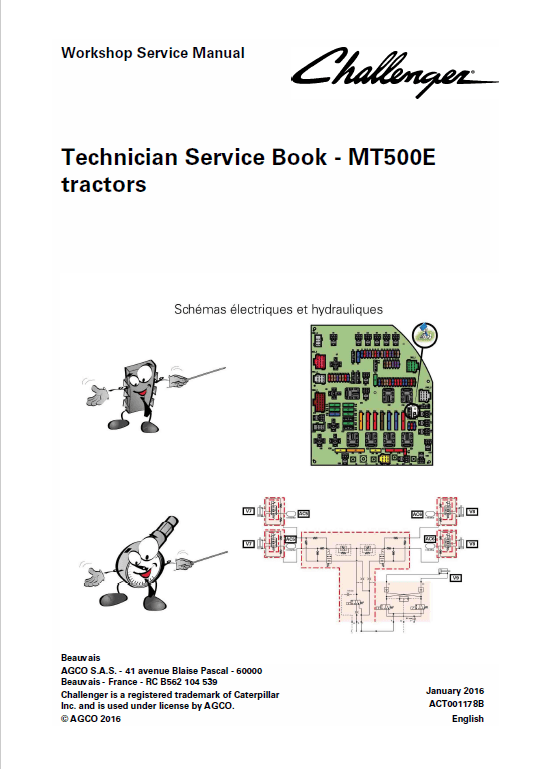

Technician Service Book: This segment includes schematics and electronics for the MT500E, featuring 814 pages of in-depth technical details.

Parts Catalog: Find parts listings for the MT500E with AutoPower VI and TechStar CVT, presented in separate catalogs with 366 pages and 424 pages, respectively.

Challenger MT515E, MT525E, MT535E, MT545E Tractor Repair Workshop Manual

Product Overview

This comprehensive workshop manual is specifically designed for the AGCO Challenger MT515E, MT525E, MT535E, and MT545E tractor models. It covers the MT500E AutoPower IV, AutoPower VI, and TechStar CVT Series, providing essential technical guidance in English for the North American market. The manual, published in February 2015, is available in a convenient PDF format under the reference number ACT0009250.

The manual includes a detailed breakdown of tractor components and systems across 3,455 pages, along with an additional 814-page technician service book that focuses on schematics and electronics. Two parts catalogs are also provided, catering to both the AutoPower VI and TechStar CVT systems, with 366 and 424 pages respectively.

Key Features

- Comprehensive guidance for Challenger MT500E Series models.

- Detailed instructions across more than 3,000 pages.

- Includes technician service book and parts catalogs.

- In-depth schematics and electronics information.

- Published in PDF format for easy access and portability.

Benefits

- Provides clear instructions for maintenance and repair tasks.

- Enhances understanding of complex tractor systems and components.

- Supports effective troubleshooting with detailed schematics.

- Valuable resource for professional technicians and enthusiasts alike.

Usage Recommendations

- Ideal for technicians involved in repair and maintenance of Challenger tractors.

- Useful for training purposes and enhancing technical knowledge.

- Best used in combination with hands-on experience for practical application.

Manual Table of Contents

- Introduction

- Separation of Assemblies

- Engine

- Clutch

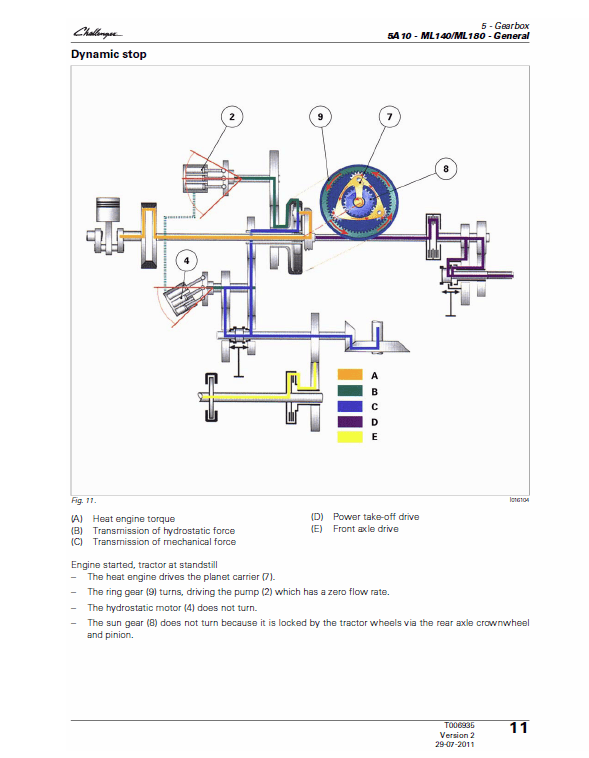

- Gearbox

- Rear Axle

- Power Take-Off

- Front Axle

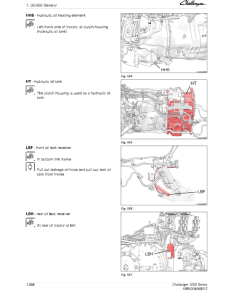

- Hydraulics

- Electricity

- Electronics

- Operator Environment

- Accessories

- Services Tools

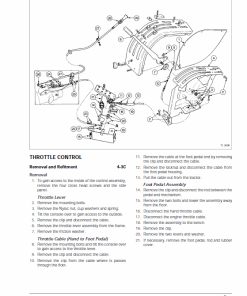

MT515E, MT525E, MT535E, MT545E Manual Extract – Power Take-Off

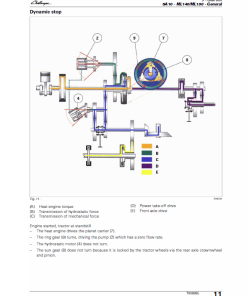

The rear PTO (Power Take-Off) system features a housing attached to the “HA180” rear axle, accommodating all rear PTO components. It includes several key elements:

- The Clutch: Located on the upper shaftline, it precedes the PTO housing and manages movement transmission.

- Upper Shaftline: Equipped with a shaft and gears transmitting motion from the clutch to the driven gears.

- Lower Shaftline: Receives motion from the upper shaftline, transmitting it to implements via an output shaft, available with varying lengths and spline configurations (6, 20, or 21 splines).

- The Brake: Positioned behind the clutch piston, it engages when the PTO is inactive, thanks to pressure maintained by spring washers.

- The Controls: Activated by solenoid valves at the rear of the housing, these controls default to a neutral position when not supplied.

Proper lubrication of rear PTO components is crucial:

- The Clutch and Upper Shaftline: Oil is delivered under pressure to these areas through internal lines, regulated by a nozzle and multiple restrictors.

- The Lower Shaftline: Lubricated via splash and targeted oil jet, ensuring efficient operation of internal lines.

Only logged in customers who have purchased this product may leave a review.

Related products

Challenger

Reviews

There are no reviews yet.