Challenger MT645E, MT655E, MT665E, MT675E, MT685E Tractor Workshop Manual

$40.00

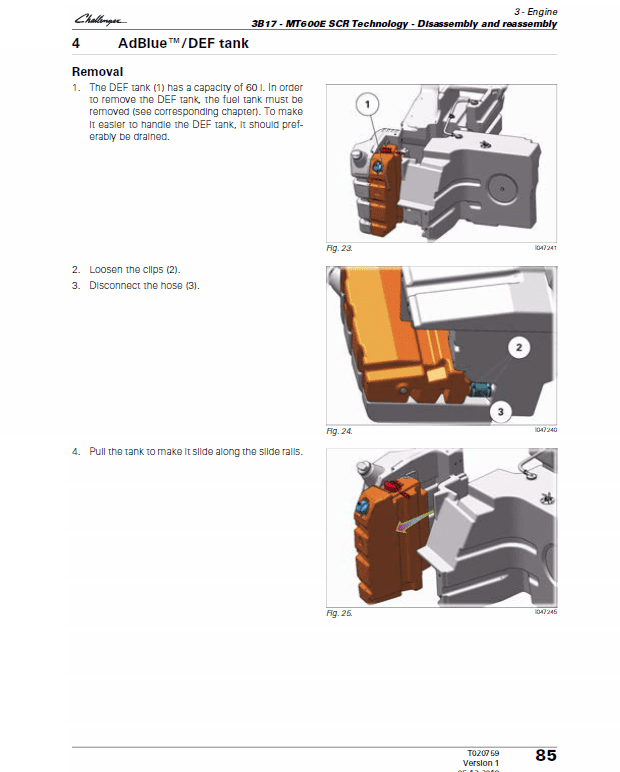

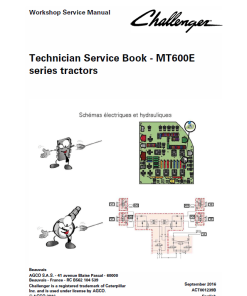

Enhance your maintenance capabilities with the Challenger MT645E, MT655E, MT665E, MT675E, MT685E Tractor Workshop Manual, offering comprehensive guidance over 1790 pages. This essential manual includes detailed schematics and electronics insights in the Technician Service Book MT600E spanning 350 pages, ensuring thorough understanding and troubleshooting. Additionally, the Parts Catalog MT600E covers 392 pages of crucial component details.

Challenger MT645E, MT655E, MT665E, MT675E, MT685E Tractor Repair Workshop Manual

Product Overview

This comprehensive repair manual covers the AGCO Challenger MT600E Series Tractors, featuring detailed service information essential for maintenance and repair operations. Models included are the MT645E, MT655E, MT665E, MT675E, and MT685E.

Publication Date: November 2014

Document Number: ACT0004360

Region: North America

Language: English

Format: PDF

Total Pages:

- Workshop Manual: 1790 pages

- Technician Service Book (Schematics and Electronics): 350 pages

- Parts Catalog: 392 pages

For more details, visit the AGCO Challenger Website.

Table of Contents

- Introduction

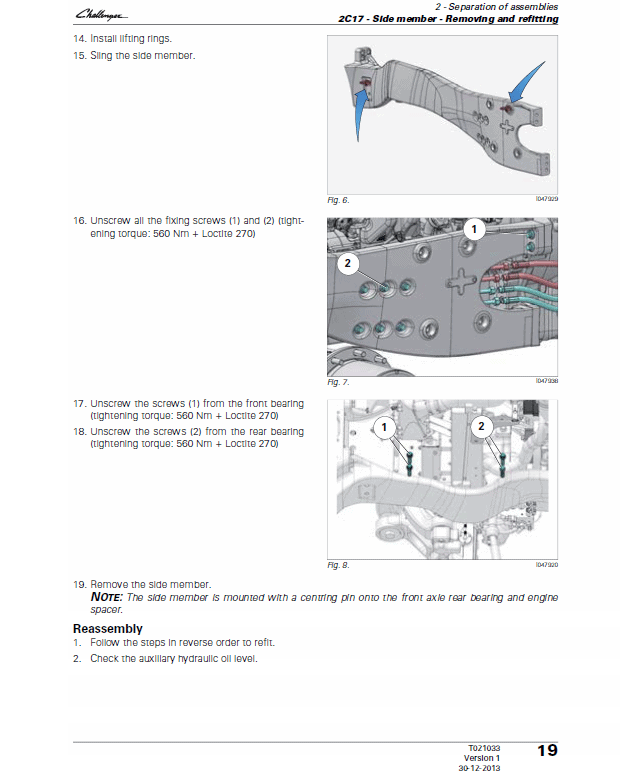

- Separation of Assemblies

- Engine

- Clutch

- Gearbox

- Rear Axle

- Power Take-off

- Front Axle

- Hydraulics

- Electricity

- Electronics

- Cab

- Accessories

- Service Tools

Key Features

- Expertly written with a detailed schematic and electronic sections.

- Includes a comprehensive parts catalog.

- Covers all critical aspects of repair and maintenance.

Benefits

- Helps technicians efficiently diagnose and repair tractor issues.

- Provides in-depth knowledge of the entire MT600E tractor series.

- Simplifies the acquisition and replacement of parts.

Usage Recommendations

- Refer to this manual for troubleshooting and maintenance tasks.

- Use the schematics for understanding complex electrical systems.

- Consult the parts catalog for ordering replacements.

Component Details

MT645E, MT655E, MT665E, MT675E, MT685E Manual Error Code

Compressor: The compressor assembly includes its clutch and pulley, crucial for refrigerant flow. It compresses low-pressure R134a gas to high pressure efficiently.

Electromagnetic Clutch: Facilitates compressor operation using a magnetic field for engagement. It’s equipped with a stationary induction coil and rotor, creating a magnetic pull to start the compressor.

Precautions are necessary when changing parts like the evaporator, condenser, dryer, compressor, or regulator to ensure system integrity.

Condenser: The condenser transforms high-pressure gas from the compressor into liquid, withstanding temperature fluctuations. Effective cooling is maintained between 49 u00b0C to 77 u00b0C while preventing damage to cooling fins for optimal operation.

Only logged in customers who have purchased this product may leave a review.

Related products

Challenger

Reviews

There are no reviews yet.