Challenger MT835C, MT845C, MT855C, MT865C, MT875C Tractor Service Manual

$40.00

Enhance your understanding and maintenance of Challenger tractors with these comprehensive manuals. Suitable for models MT835C, MT845C, MT855C, MT865C, and MT875C, these resources are essential for any owner or technician.

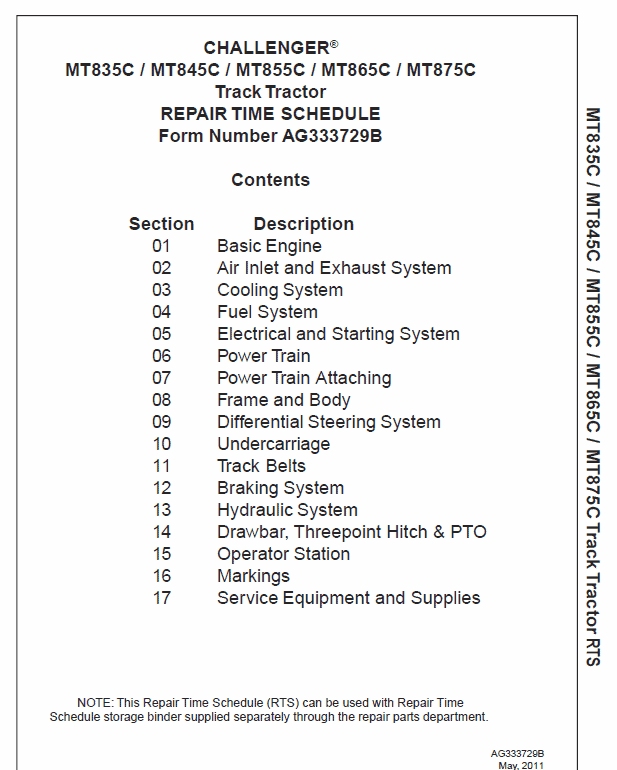

Workshop Manual: 2,963 Pages

Repair Schedule Manual: 840 Pages

Format: PDF

Book Numbers: 79033095 & AG333729B

Language: English

Issued: July, 2016

Challenger MT800C Series Tractor Service Manual

Product Overview

The Service Manual for the AGCO Challenger MT800C Series Tractor provides comprehensive guidance on maintaining and repairing your Challenger MT835C, MT845C, MT855C, MT865C, and MT875C models. Available in PDF format, this manual is an invaluable resource for ensuring your tractor operates at peak performance. It comprises two volumes: the Workshop Manual with 2963 pages and the Repair Schedule Manual with 840 pages, issued in July 2016.

Key Features

- Format: PDF

- Language: English

- Book Numbers: 79033095 & AG333729B

- Extensive workshop and repair procedures

- Issued: July 2016

Benefits

- Detailed instructions ensure your tractor is maintained and repaired correctly.

- Comprehensive coverage across all tractor systems and components.

- Save time and resources by performing repairs in-house with confidence.

Usage Recommendations

- Ensure all safety procedures are followed as outlined in the manual.

- Use for routine maintenance as well as major repairs.

- Reference the manual before beginning any complex repair task.

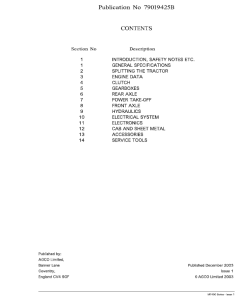

Table of Contents

Here is a quick overview of the subjects covered in the manual:

- INTRODUCTION

- ENGINE

- POWERTRAIN

- FRAME

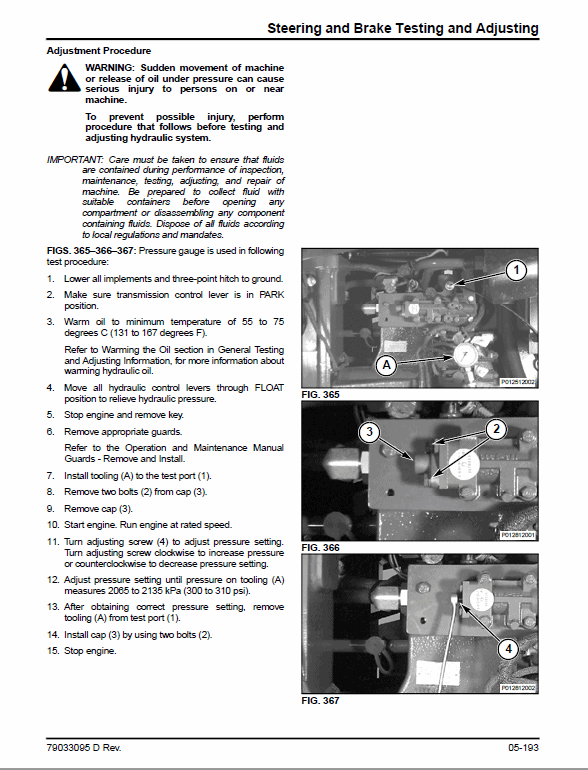

- STEERING AND BRAKE SYSTEM

- IMPLEMENT AND THREE-POINT HITCH HYDRAULIC SYSTEMS

- ELECTRICAL

- AIR SYSTEM

- VIRTUAL TERMINAL

- CAB

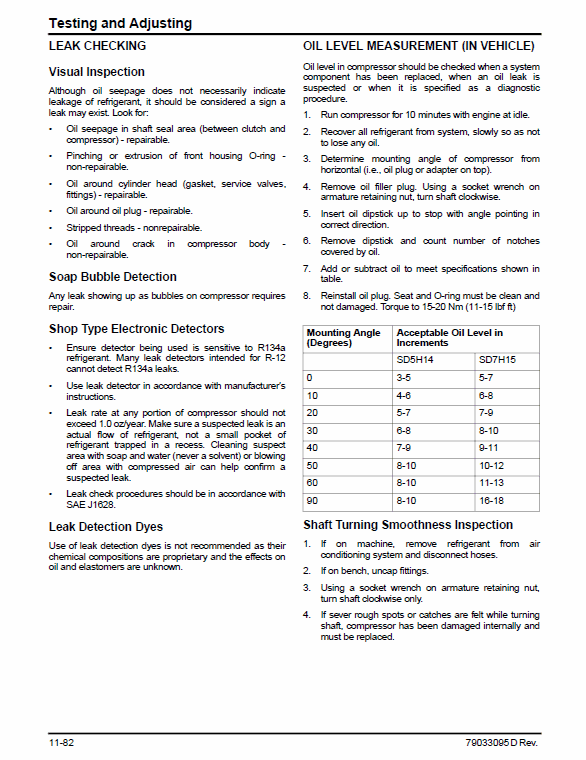

- HEATING VENTILATION AND AIR CONDITIONING (Volume 2)

- BALLASTING

- APPEARANCE GROUP

- ELECTRONICS

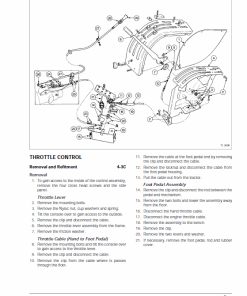

Visual Inspection Guidelines

Ensure safe and effective inspection of your tractor by following these guidelines. Use materials such as cardboard or paper to identify pinhole leaks, and avoid using hands to inspect for leaks as high velocity oil streams can be harmful.

Steps for Visual Inspection:

- Move the machine to a smooth, level surface.

- Lower all implements and the three-point hitch to the ground.

- Set the transmission control lever to the Park position.

- If needed, warm the oil to a minimum of 60u00b0C (140u00b0F).

- Cycle all hydraulic control levers through the Float position to relieve pressure.

- Stop the engine and remove the key.

- Remove necessary guards for inspection.

Conduct the following visual inspections:

- Measure the oil level.

- Inspect the oil for air immediately after stopping the machine using the sight gauge next to the PTO shaft.

- Remove and check filter elements for particles. Use a magnet to distinguish metallic particles.

- Inspect all oil lines and connections for leaks or damage.

- Check control linkages for any broken or damaged components.

Only logged in customers who have purchased this product may leave a review.

Related products

Challenger

Reviews

There are no reviews yet.