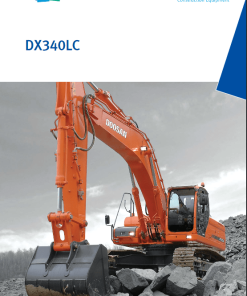

Doosan DX210W Excavator Service Manual

$35.00

Format: PDF

Language: English

Publication No: K1017314AE

Serial Number: 5001 and Up

This comprehensive service repair manual for the Doosan DX210W Excavator contains detailed procedures and illustrations over its 1186 pages. Ideal for maintenance and repair professionals.

Doosan DX210W Excavator Service Manual

Product Overview

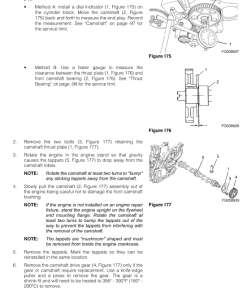

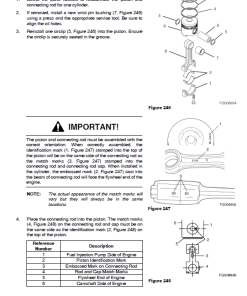

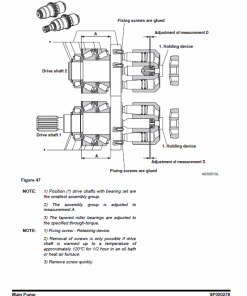

The Doosan DX210W Excavator Service Manual provides comprehensive information necessary for the servicing of the Doosan DX210W Excavator. This guide encompasses detailed service procedures, presented with photographs and illustrations to facilitate the accurate identification and assembly of components.

Format: PDF

Language: English

Publication No: K1017314AE

Serial Number: 5001 and Up

Total Pages: 1186

Key Features

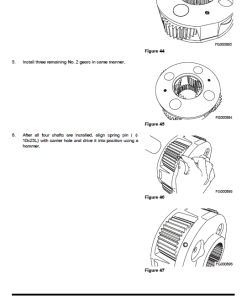

- Comprehensive service procedures with clear, sequential steps.

- Includes detailed schematics of major engine systems for troubleshooting.

- Contains safety information and warnings to assist in safe operations.

Benefits

- Enhances troubleshooting capabilities with detailed diagrams and photos.

- Facilitates safe operation and maintenance practices.

- Serves as an authoritative reference for both routine maintenance and repairs.

Usage Recommendations

- Refer to the table of contents to quickly locate the required service procedures.

- Carefully follow the safety precautions outlined in the manual.

- Regularly inspect the equipment using the guidance provided in the manual to prevent early wear and damage.

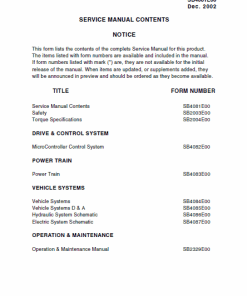

Instruction Table of Contents

This manual covers various aspects including:

- Safety: Wheel Excavator Safety

- Specifications: Detailed specifications for DX210W

- General Maintenance: Procedures and standard torques

- Upper Structure: Cabin, Fuel System, Swing Mechanisms

- Lower Structure and Chassis: Valves, Axles, Solenoid Operations

- Engine and Drive Train: Transmission, Bearings, and Pump Details

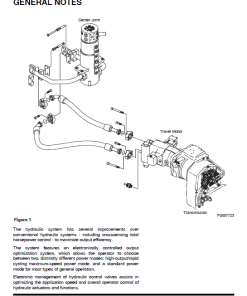

- Hydraulics: System diagnostics and component functions

- Electrical System: Wiring and component schematics

- Attachments: Boom, Arm, and Bucket operations

Instruction Extract

Inspection

The center joint must be checked for any signs of external oil leakage every 2,000 operating hours. Leaking or faulty O-rings may indicate contamination inside the assembly that can lead to excessive wear or early failure. In such cases, thorough overhaul, repair, or replacement is recommended.

Testing

For pressure testing through the center joint, create a test kit using the following components:

- 700 bar (10,000 psi) pressure gauge

- Adapters, connectors, and flanges matching high-pressure piping of the excavator

- High-pressure relief valve set to 1.5 times the maximum system pressure

- Stop valve and manually operated changeover valve

Install the changeover valve upstream from a high-pressure port, connect the pressure gauge downstream from a body port, and set up the remaining components according to the block diagram workflow. This setup assists in pressurizing and testing the center joint for leakage.

Note: Similar setups can be devised for other components, including the drain port side.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.