Doosan DX225LC Excavator Service Manual

$34.00

Comprehensive Guide: 816 Pages

This PDF manual provides detailed service and repair instructions for the Doosan DX225LC Excavator. Written in English and applicable for serial numbers 5001 and up.

Publication Number: K1048003E

Doosan DX225LC Excavator Service Manual

Product Overview

The Doosan DX225LC Excavator Service Manual provides comprehensive guidance on servicing the DX225LC model. Offered in PDF format, this manual is composed of 816 pages and is written in English. It is an essential resource for owners and operators, covering machines with serial numbers beginning from 5001.

Key Features

- Publication Number: K1048003E

- Language: English

- Format: PDF

- Page Count: 816 pages

Benefits

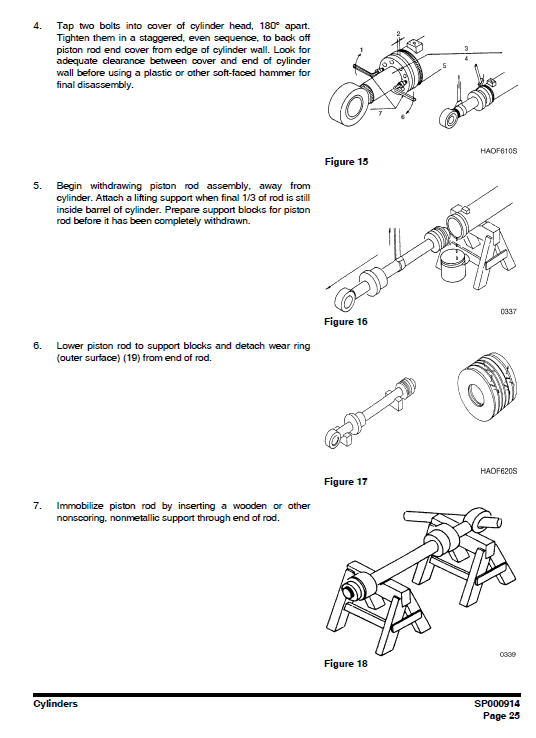

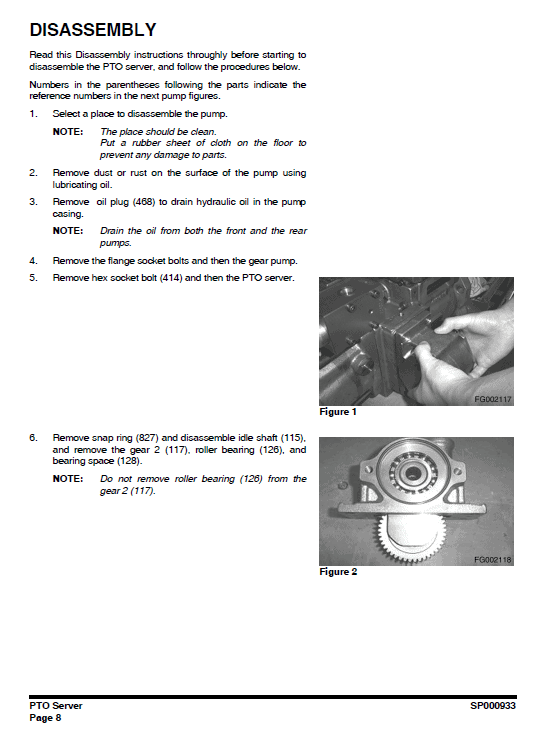

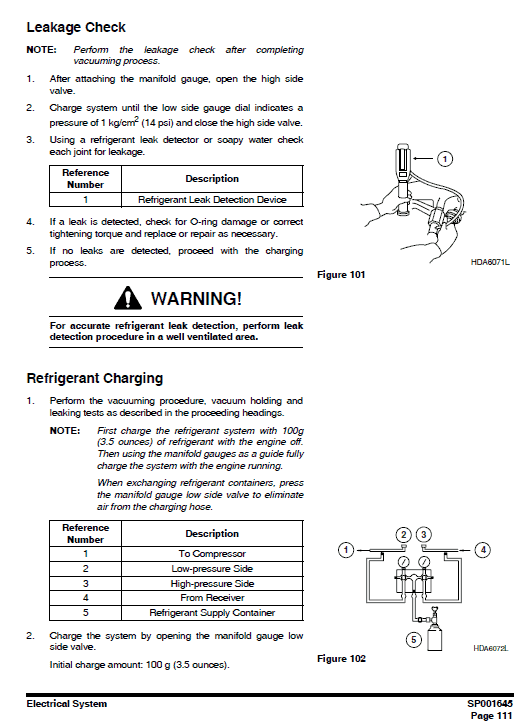

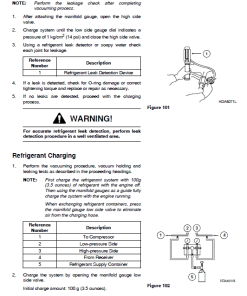

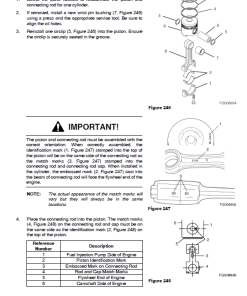

- Comprehensive Coverage: Detailed step-by-step service procedures for the DX225LC Excavator.

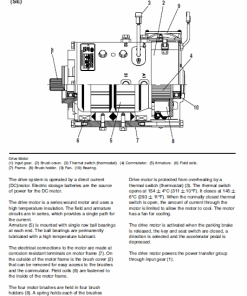

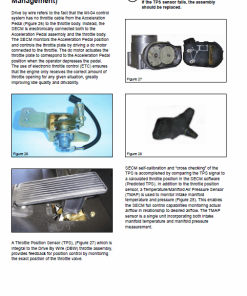

- Visual Aids: Includes photographs and drawings to assist in locating and identifying components.

- Safety Information: Integral safety precautions are highlighted throughout the manual.

Usage Recommendations

- Consult the Table of Contents for quick access to specific service procedures.

- Follow detailed troubleshooting guides for each major engine system.

- Always observe safety warnings outlined in the manual and labels on equipment.

Contents Overview

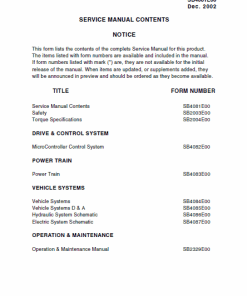

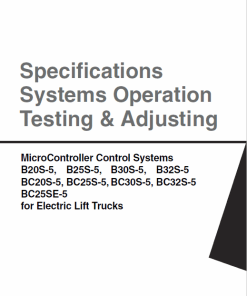

The Table of Contents extensively covers a variety of sections crucial to the maintenance and service of the Doosan DX225LC Excavator. Some key sections include:

- Safety

- Specifications

- General Maintenance Procedures

- Upper Structure Components

- Lower Structure and Chassis

- Engine and Drive Train

- Hydraulic Systems

- Electrical Systems

- Attachments

Troubleshooting and Repair Guide

The service manual provides an extensive troubleshooting guide to address common and specific issues. Below is an extract of common problems, possible causes, and recommended solutions:

| Problem | Possible Cause | Remedy |

|---|---|---|

| Secondary pressure does not increase. | Low primary pressure. | Check primary pressure. |

| Broken spring. | Replace spring. | |

| Spool sticking. | Clean, repair, or replace. | |

| Excess spool to casing clearance. | Replace spool casing. | |

| Worn or loose universal joint (handle) subassembly. | Repair or replace U-joint subassembly. | |

| Secondary pressure too high. | Dirt or interference between valve parts. | Clean, repair, or replace. |

| Secondary pressure too high. | Return line pressure too high. | Redirect return line. |

| Secondary pressure too high. | Dirt or interference between valve parts, or worn spool sticking intermittently. | Clean, repair, or replace. |

| Interference or binding on spool return spring. | Clean, repair, or replace. | |

| Interference, restriction, or unsteady pressure in tank return line. | Repair or reroute tank return line. | |

| Air bubbles in piping (temporary) or air leak”, “

Only logged in customers who have purchased this product may leave a review. Related products

$34.00

$34.00

$34.00

$33.00

LoginRegister |

Reviews

There are no reviews yet.