Doosan DX350LC Excavator Service Manual

$34.00

Comprehensive Guide: This service repair manual spans 828 pages and is designed specifically for the Doosan DX350LC Excavator.

Format: PDF

Language: English

Publication Number: K1046036E

Applicable Serial Numbers: Starting from 5980

For further details, visit the comprehensive service repair guide for the Doosan DX350LC Excavator.

Doosan DX350LC Excavator Service Manual

Product Overview

The Doosan DX350LC Excavator Service Manual is an essential resource for servicing your heavy machinery. Available in PDF format and written in English, this comprehensive guide provides all the details needed to maintain and repair the DX350LC from serial number 5980 and onward. Featuring 828 pages of in-depth information, itu2019s an invaluable tool for any service and maintenance task.

Key Features

- Format: PDF

- Language: English

- Publication Number: K1046036E

- Serial Number Coverage: 5980 and up

- Total Pages: 828

Benefits

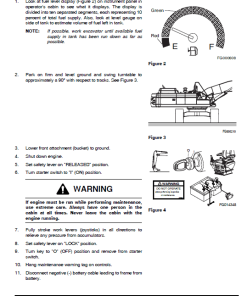

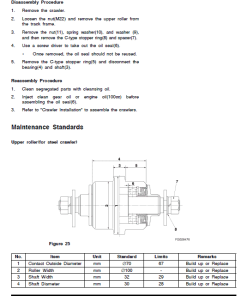

- Detailed and step-by-step service procedures for easy maintenance.

- Comprehensive visual aids including photographs and drawings.

- Special emphasis on safety with dedicated sections and warning labels.

- Includes troubleshooting and repair schematics for major engine systems.

- Structured Table of Contents for fast access to needed information.

Usage Recommendations

- Consult the Table of Contents for quick navigation to specific service procedures.

- Strictly adhere to the included safety precautions for safe operation.

- Ensure all components are clean and free of contaminants before assembly.

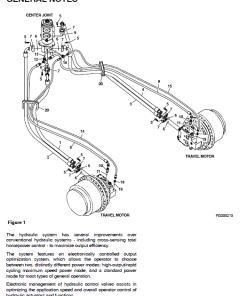

- Use as a reference for troubleshooting, testing, and adjusting the hydraulic system.

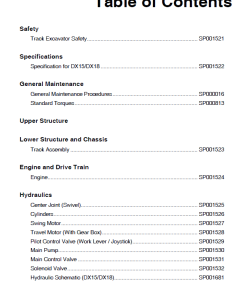

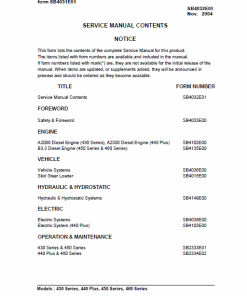

Instruction Table of Content

The manual is organized into several key sections:

- Safety: Track Excavator Safety (SP000907)

- Specifications: Details about DX350LC (SP001772)

- General Maintenance: Maintenance Procedures and Standard Torques (SP000016, SP000813)

- Upper Structure: Cabin, Counterweight, Fuel System, and more (SP001737 – SP001856)

- Lower Structure and Chassis: Including Track Assembly (SP001741)

- Engine and Drive Train: Covering the main pump drive coupling (SP000026)

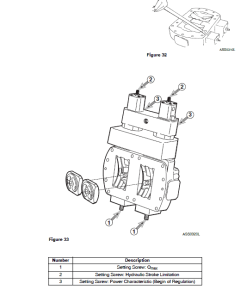

- Hydraulics: Troubleshooting and component information (SP001773 – SP001774)

- Electrical System: System specifications and schematics (SP001776, SP001768)

- Attachments: Boom, Arm, and Bucket (SP001851, SP001852)

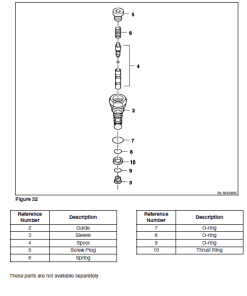

Note: If a solenoid valve fails to function correctly, it may be contaminated with foreign matter. Disassemble the valve to inspect and clean any contaminants, then reassemble after thorough washing.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.