Doosan DX35Z Excavator Service Manual

$34.00

This comprehensive Doosan DX35Z Excavator Service Repair Manual consists of 621 pages in a convenient PDF format. Written in English, it provides detailed guidance for maintenance and repair. This manual is applicable to excavators with Serial Number: 5001 and Up.

Publication No: K1025197E

Doosan DX35Z Excavator Service Manual

Product Overview

The Doosan DX35Z Excavator Service Manual is an essential guide for professionals responsible for servicing this heavy machinery. The manual is available in PDF format, written in English, and comprises a comprehensive 621 pages. Designed for serial numbers starting from 5001, this publication (No. K1025197E) is your go-to resource for troubleshooting and maintaining the DX35Z excavator.

Key Features

- Detailed service procedures with step-by-step instructions

- Visual aids including photographs and drawings for component identification

- Extensive table of contents for easy navigation

- Schematics for major engine systems

- Comprehensive safety information and specific warnings

Benefits

- Helps ensure proper maintenance and longevity of your excavator

- Facilitates accurate troubleshooting and repair

- Enhances safety with detailed precautions and warnings

- Saves time with a well-organized structure and content layout

Usage Recommendations

- Utilize the manual for both routine maintenance and in-depth repairs

- Regularly refer to the safety section to maintain workplace safety

- Keep a digital or printed copy accessible for quick reference

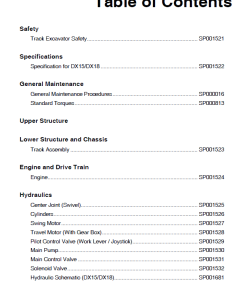

Contents Overview

- Safety

- Track Excavator Safety …………………………………………………………….. SP001061

- Specifications

- Specification for DX35Z ……………………………………………………………. SP001062

- General Maintenance

- General Maintenance Procedures ……………………………………………… SP000016

- Standard Torques …………………………………………………………………….. SP000813

- Upper Structure

- Cabin ………………………………………………………………………………………. SP001063

- Fuel Tank………………………………………………………………………………… SP001079

- Lower Structure and Chassis

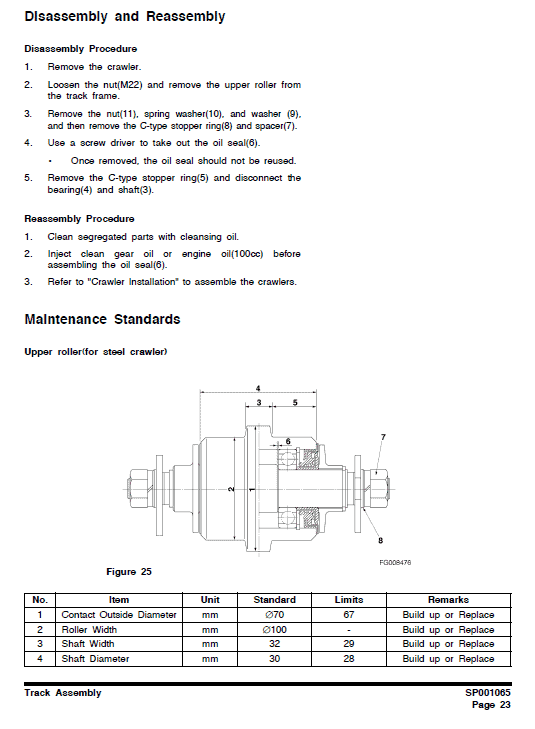

- Track Assembly ……………………………………………………………………….. SP001065

- Engine and Drive Train

- Drive Coupling (Main Pump) …………………………………………………….. SP001066

- Hydraulics

- Accumulator……………………………………………………………………………… SP000028

- Center Joint (Swivel) ………………………………………………………………… SP001067

- Electrical System

- Electrical System …………………………………………………………………….. SP001077

- Electrical Schematic (DX35Z) ……………………………………………………. SP001078

- Attachments

- Working Attachments………………………………………………………………… SP001075

- Bucket……………………………………………………………………………………… SP001076

Instruction Extract: Understanding the Swash Plate Motor

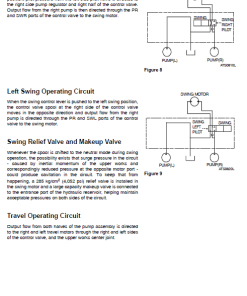

The swash plate motor includes a cylinder block with nine pistons. The block’s end face contacts a valve plate with two ports (B and C) that alternate the pressure distribution. Here’s the principle of torque generation:

- When high-pressure oil enters port B, it applies force to the inclined surface, producing a reaction force and resultant torque transferred via the spline to the shaft.

- Introducing high-pressure oil to port C reverses the rotation.

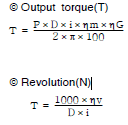

- Formulae for output torque and revolution account for factors like pressure, flow, and mechanical efficiencies.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.