Doosan DX490LC-3 and DX530LC-3 Excavator Service Manual

Product Overview

The Doosan DX490LC-3 and DX530LC-3 Excavator Service Manual

is an essential resource for professionals involved in the maintenance and repair of these powerful machines.

This comprehensive guide, with 1992 pages, is available in PDF format and written in English.

It is suitable for serial numbers 10001 and above, and is identified by Publication No: 950106-00259E.

Key Features

- Format: PDF

- Language: English

- Publication No: 950106-00259E

- Applicable Serial Numbers: 10001 and Up

- Pages: 1992

Benefits

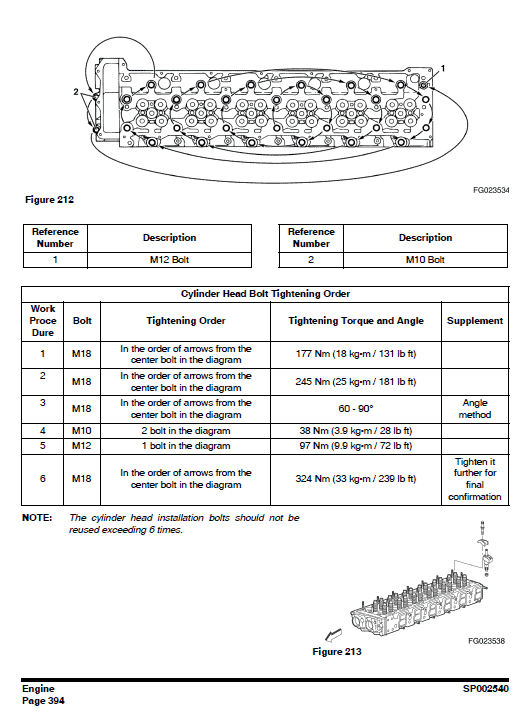

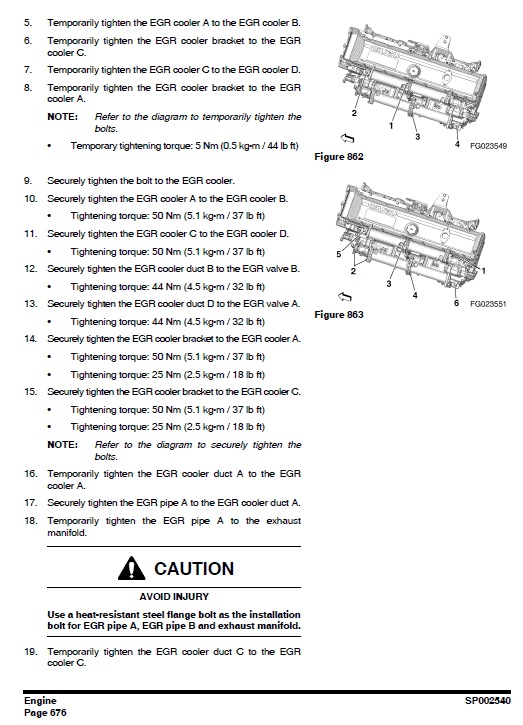

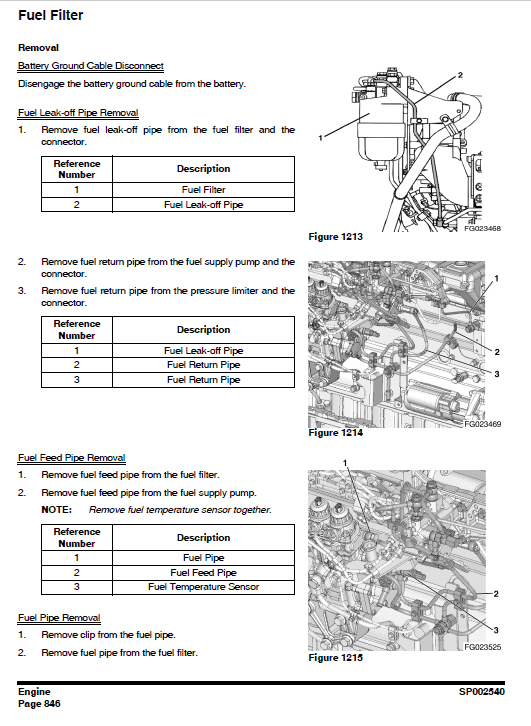

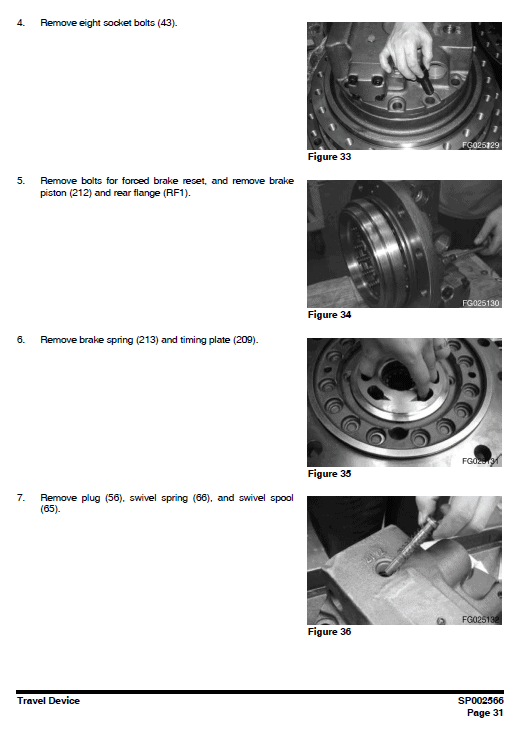

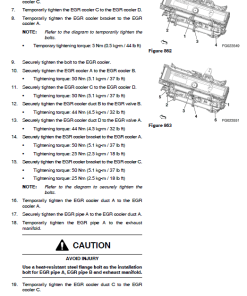

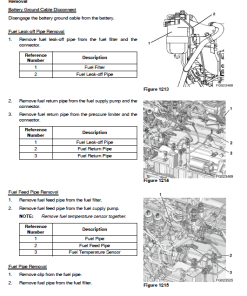

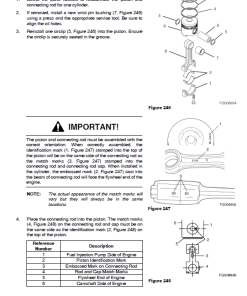

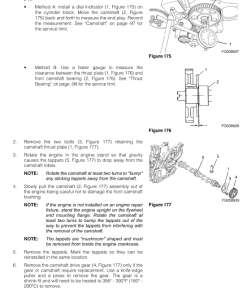

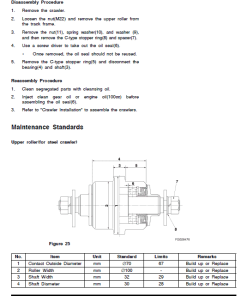

- Detailed, step-by-step service procedures.

- Comprehensive coverage with both photographs and drawings.

- Safety instructions and warnings are included to prevent accidents.

- Provided schematics for major engine systems to assist troubleshooting.

Usage Recommendations

- Follow the recommended sequence in the service procedures for optimal repair and maintenance.

- Utilize the table of contents for quick navigation to the desired service topic.

- Observe all safety precautions mentioned both in this manual and in the owner/operation/maintenance document.

- Pay close attention to warning labels and safety information presented at relevant sections.

Manual Content Overview

The following sections are included in the Doosan DX490LC-3 and DX530LC-3 Excavator Service Manual:

- Safety: Track Excavator Maintenance Safety.

- Specifications: Detailed specifications for models DX490LC-3 and DX530LC-3.

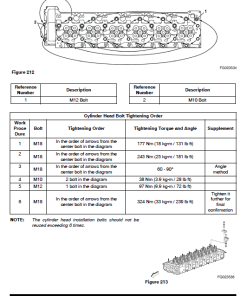

- General Maintenance: Instructions, standard torques, and maintenance guidelines.

- Upper Structure: Coverage of the cabin, counterweight, fuel system, and more.

- Lower Structure and Chassis: Track assembly and related components.

- Engine and Drivetrain: Engine details including coolants and drive coupling.

- Hydraulics: Troubleshooting, testing, adjustment, and component specifics.

- Electrical System: Electrical system coverage and schematics.

- Attachments: Information on the boom, arm, and bucket.

Instruction Extracts

IAT and MAF Sensors: These sensors are crucial for monitoring engine intake conditions. The IAT sensor measures air temperature while the MAF sensor monitors airflow. They aid in controlling fuel injection and maintaining engine performance under varying loads.

Intake Throttle Valve: Found on the intake duct, this component is pivotal for managing exhaust temperature, especially during DPD regeneration by regulating intake air volume.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.