Doosan DX55 Excavator Service Manual

Product Overview

The Doosan DX55 Excavator Service Manual is an essential resource for maintaining and servicing your DX55 Excavator. Available in PDF format, this comprehensive manual is written in English and tailored for machines with serial numbers 50001 and up. The document contains 842 pages of detailed guidance for service technicians.

Key Features

- Format: PDF

- Language: English

- Publication Number: K1038080E

- Covers Serial Numbers: 50001 and Up

Benefits

- Comprehensive guide with 842 pages of detailed instructions.

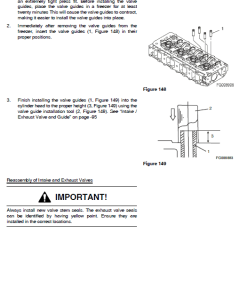

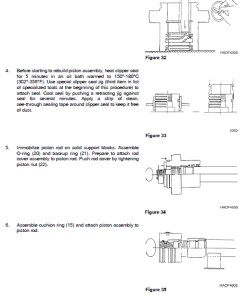

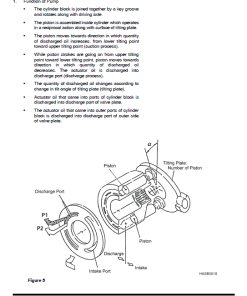

- Step-by-step procedures illustrated with photographs and drawings.

- Includes schematics of major engine systems for troubleshooting.

- Covers extensive safety information and specific hazard warnings.

Usage Recommendations

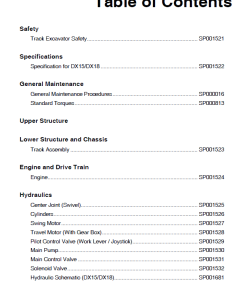

- Refer to the Table of Contents to quickly locate needed service procedures.

- Always observe the safety information provided in the manual.

- Follow the procedures sequentially as listed for optimal results.

Content Overview

This manual is organized into several critical sections to facilitate easy navigation and reference:

- Safety – Track Excavator Safety (SP001478)

- Specifications – For DX55 (SP001479)

- General Maintenance – Procedures and Standard Torques (SP000016, SP000813)

- Upper Structure – Including Cabin and Swing Bearing (SP001480, SP001551)

- Lower Structure and Chassis – Track Assembly (SP001481)

- Engine and Drive Train – Engine and Drive Coupling (SP001434, SP001482)

- Hydraulics – Accumulator, Swing Motor, and Main Pump (SP000028, SP001485, SP001488)

- Electrical System – Including Electrical Schematic (SP001493, SP001494)

- Attachments – Boom, Arm, and Bucket (SP001495, SP001496)

Instruction Extract: Pinion Clutch Assembly

n

Pinion Clutch Assembly: Manually rotate the pinion clutch assembly in the drive direction (Figure 366). It should rotate freely and lock when turned in the opposite direction. If not, the assembly should be replaced. The assembly should slide smoothly on the shaft (Figure 367). Rust, excessive grease, or damage could impede smooth sliding. In such cases, clean the shaft and assembly or replace the damaged component.

Ball Bearing Inspection: Rotate each ball bearing holding the pinion clutch assembly (Figure 368). Replace any defective ball bearings that do not rotate smoothly or exhibit excessive play.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.