Doosan M200-V Wheel Loader Service Manual

$33.00

This comprehensive repair manual is designed specifically for the Doosan M200-V Wheel Loader. Spanning 584 pages, it offers detailed instructions for maintenance and repairs.

Format: PDF

Language: English

Publication Number: 023-00055AE

Applicable Serial Numbers: S 1001 and Up (Tier I & II)

Doosan M200-V Wheel Loader Service Manual

Product Overview

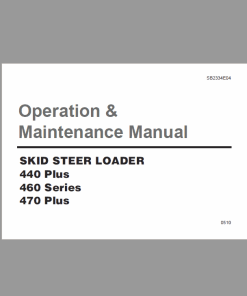

The Doosan M200-V Wheel Loader Service Manual is an essential resource for maintenance and repair of the M200-V model. The manual is formatted as a PDF in English, with Publication No: 023-00055AE, covering serial numbers S 1001 and above (Tier I & II). It spans 584 pages, providing comprehensive guidance for servicing procedures.

Key Features

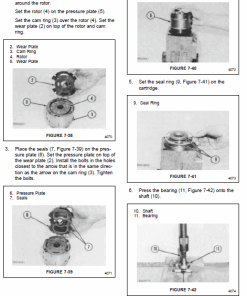

- Detailed service procedures with step-by-step instructions.

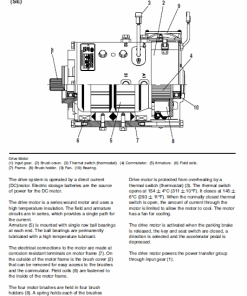

- Illustrations including photographs and drawings for easy component identification.

- Comprehensive safety information and warnings included throughout.

- Service procedures for a wide range of components including the hydraulic system, engine, drive train, and electrical system.

- Includes schematics for major engine systems to aid troubleshooting and repair.

Benefits

- Ensures safe and efficient operation by adhering to the recommended safety precautions.

- Facilitates expert-level maintenance and repair without needing extensive experience.

- Improves longevity and performance of the Doosan M200-V Wheel Loader.

- Reduces downtime by expediting troubleshooting and repairs with organized content.

Usage Recommendations

- Consult the table of contents for quick access to specific service procedures.

- Observe all safety warnings and precautions outlined in the manual.

- Refer to the introductory schematic for each system when troubleshooting.

- Use this manual in conjunction with the owner/operation/maintenance publication for comprehensive understanding.

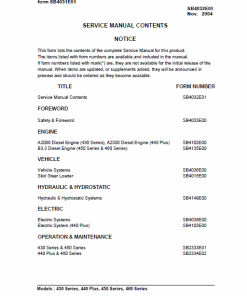

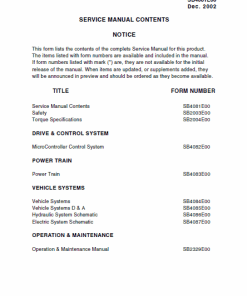

Table of Contents Highlights

- Safety: Comprehensive safety guidelines specifically for wheel loader operation.

- Specifications: Detailed specifications for the Mega 200-V model.

- General Maintenance: Standard procedures and torques for general upkeep.

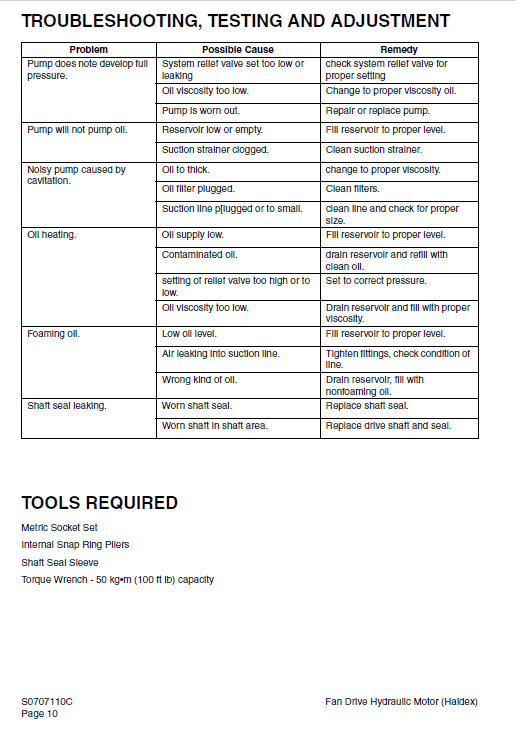

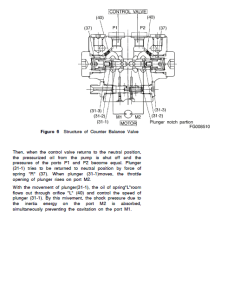

- Hydraulics: Detailed diagrams and information on hydraulic systems and components.

- Electrical System: Insights into the electrical components and schematics.

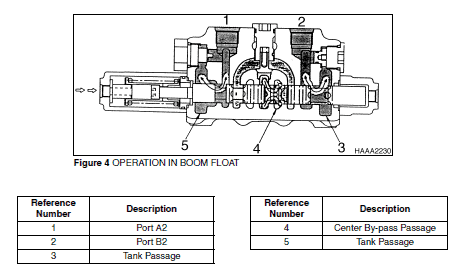

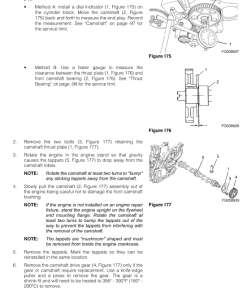

When the control lever is pushed down from the Down position to the Float position, the boom spool moves, opening the neutral passage. This allows the booms to float over ground surfaces, adapting to its irregularities. The main relief valve, situated between the neutral and low-pressure oil passages, and the port relief valve, located in the bucket spool section, function as key safety features controlling oil flow.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.