Gehl Z35 Gen 2, Mustang 350Z Nxt 2 Compact Excavator Repair Service Manual

$40.00

Gehl Z35 Gen 2 & Mustang 350Z Nxt 2 Excavator Manuals

Enhance your knowledge and maintain your excavator with the comprehensive manuals applicable for the Gehl Excavator Model Gehl Z35 Gen 2 and Mustang 350Z Nxt 2.

Available Manuals:

- Repair Service Manual – 730 Pages

- Operators Manual – 318 Pages

- Parts Manual – 424 Pages

All manuals are available in PDF format and are written in English.

Comprehensive Maintenance and Repair Guide

Product Overview

This guide provides an extensive breakdown of maintenance procedures, technical specifications, and troubleshooting techniques for machinery. It is designed to enhance the longevity and performance of your equipment by ensuring all components are optimally serviced and managed.

Key Features

- General Cautions for Maintenance Work:

- Includes safety guidelines for conducting maintenance, disassembly, reassembly, and handling of hydraulic components.

- Outlines best practices for hydraulic hose installation, seal handling, and air release procedures.

- Technical Data:

- Presents detailed specifications, dimensions of working areas, and weight lists of major parts.

- Offers hydraulic and electrical schematics, wiring diagrams, and recommendations for fuel, lubricants, and grease.

- Details lifting capacities and periodic inspection schedules.

- Service Standards:

- Defines performance standards for the machine, engine, undercarriage, and hydraulic equipment.

- Specifies tightening torque values for components and pressure adjustment settings for hydraulic valves.

- Includes specifications for rubber crawlers, blade moving devices, and bucket teeth.

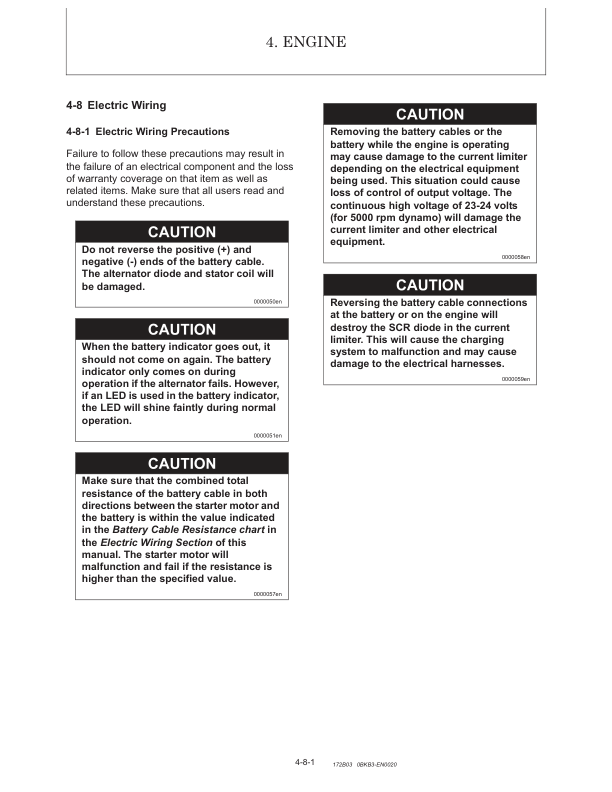

- Engine:

- Provides comprehensive servicing instructions, including valve clearance adjustments and EGR system maintenance.

- Covers detailed procedures for fuel system components, cooling systems, lubrication systems, starter motors, alternators, and the electronic control system.

- Incorporates wiring diagrams and troubleshooting methods for engine-related components.

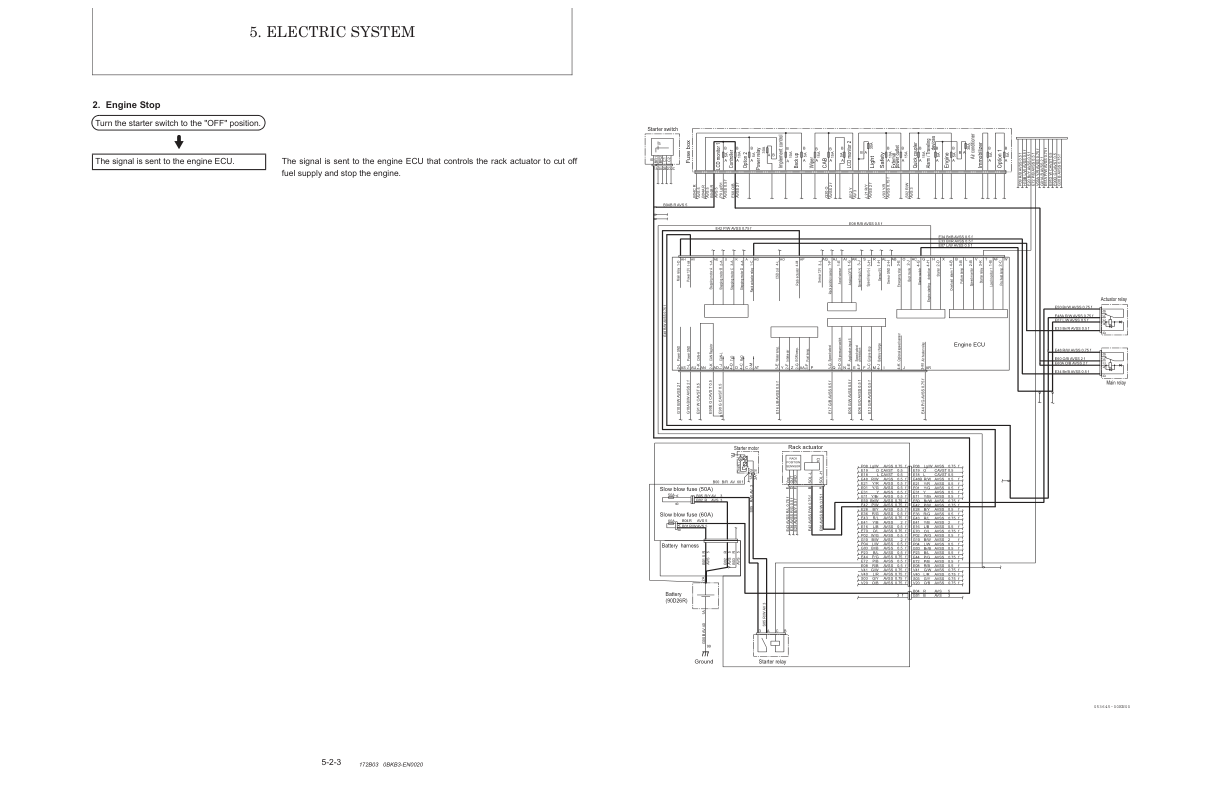

- Electric System:

- Offers an overview of electrical equipment, LCD monitor, and alarm systems.

- Describes electronic control systems for start/stop, auto deceleration, Eco mode, and engine speed/output control.

- Includes error codes and diagnostic tools for troubleshooting.

- Hydraulic System:

- Explains hydraulic circuit operations, including boom, arm, bucket, swing, and blade systems.

- Details instructions for simultaneous operations, quick couplers, and hydraulic P.T.O. (Power Take-Off).

- Covers maintenance and repair procedures for hydraulic pumps, control valves, pilot valves, swing motors, and travel motors.

- Adjustment and Repair:

- Guides on removal, reinstallation, and servicing of key components such as engine, undercarriage, controls, swing bearings, and cabin.

- Includes hydraulic system repairs, with procedures for disassembly and reassembly of hydraulic cylinders, swivel joints, and oil tanks.

- Details work implement adjustments, including quick coupler and air conditioning servicing.

- Troubleshooting:

- Provides diagnostic guides for issues like bucket release, arm movement irregularities, and thermal shocks.

- Includes quick reference tables for common problems, such as hydraulic system oil fluctuations and travel speed delays.

Benefits

- Ensures safety and efficiency in maintenance operations.

- Improves machinery performance and extends its lifespan.

- Facilitates accurate troubleshooting and quick repairs.

Usage Recommendations

- Regularly consult the guide to ensure adherence to technical specifications for optimal equipment performance.

- Follow the outlined safety and maintenance standards to prevent accidents and equipment damage.

- Utilize the troubleshooting and diagnostic sections to efficiently address technical problems.

Only logged in customers who have purchased this product may leave a review.

Related products

Articulated Loader

$36.00

$33.00

$36.00

Articulated Loader

$36.00

$33.00

Articulated Loader

$37.00

Reviews

There are no reviews yet.