Gehl Z80 Gen 2, Mustang 800Z Nxt 2 Compact Excavator Repair Service Manual

$42.00

Gehl Excavator Manuals Collection

This comprehensive set of manuals is designed for the Gehl Excavator Model Gehl Z80 Gen 2 and Mustang 800Z Nxt 2.

Available in PDF format and in English, this collection includes:

Comprehensive Maintenance and Service Manual

Product Overview

Explore our detailed maintenance and service manual, carefully crafted to provide guidance and technical details for effective maintenance work. This manual is essential for ensuring optimal performance and longevity of equipment and systems. Discover key chapters that cover safety precautions, technical data, and troubleshooting steps to ensure effective and efficient maintenance practices.

Key Chapters and Highlights

1. General Cautions for Maintenance Work

- Safety Precautions: Learn important safety protocols to uphold during maintenance to protect yourself and prevent equipment damage.

- Handling Hydraulic Systems: Master the proper techniques for handling hydraulic equipment, focusing on piping, seals, and hoses.

- Specifications: Access specifications for hydraulic hoses and important guidelines for air release in hydraulic systems.

2. Technical Data

- Specifications and Dimensions: Detailed insights into machine specifications, weight distribution, lifting capacities, and working area dimensions.

- Hydraulic and Wiring Diagrams: Schematic layouts provided for hydraulic circuits and electrical systems.

- Maintenance Schedule: Essential guidance on periodic inspections, servicing, and required lubricants to maintain system efficiency.

3. Service Standards

- Performance Standards: Understand the performance benchmarks for engines, hydraulic systems, and the undercarriage.

- Tightening Torques: A comprehensive list of torque specifications for bolts, nuts, and hydraulic fittings to ensure secure assembly.

- Pressure Adjustments: Detailed procedures for adjusting relief and brake valves.

4. Engine

- Servicing Procedures: Step-by-step servicing processes for engines, including valve adjustments and crankshaft maintenance.

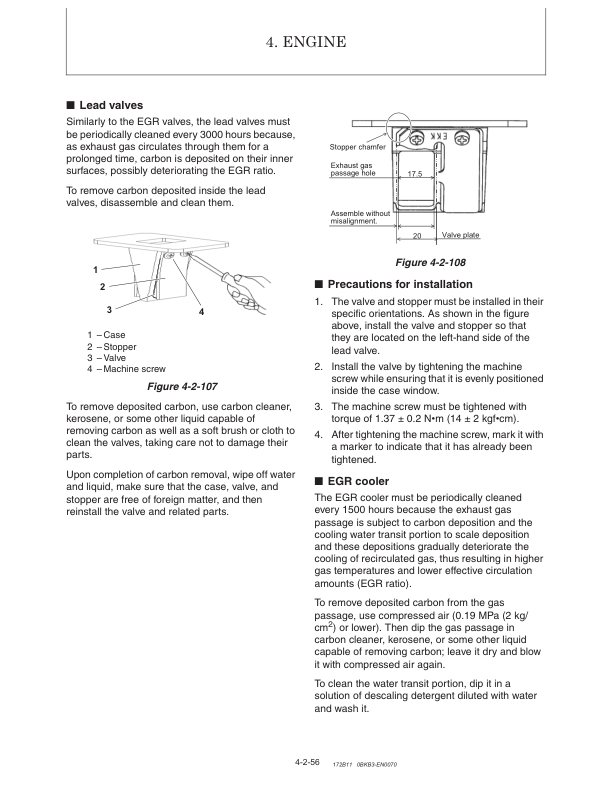

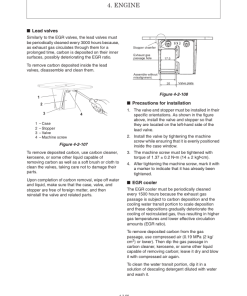

- EGR System and DPF: Overview of emission control systems like the exhaust gas recirculation (EGR) system and diesel particulate filter (DPF) maintenance.

- Cooling and Lubrication Systems: Instructions for maintaining coolant pumps and oil systems, including oil pressure checks.

- Troubleshooting: Troubleshooting guides for common engine issues.

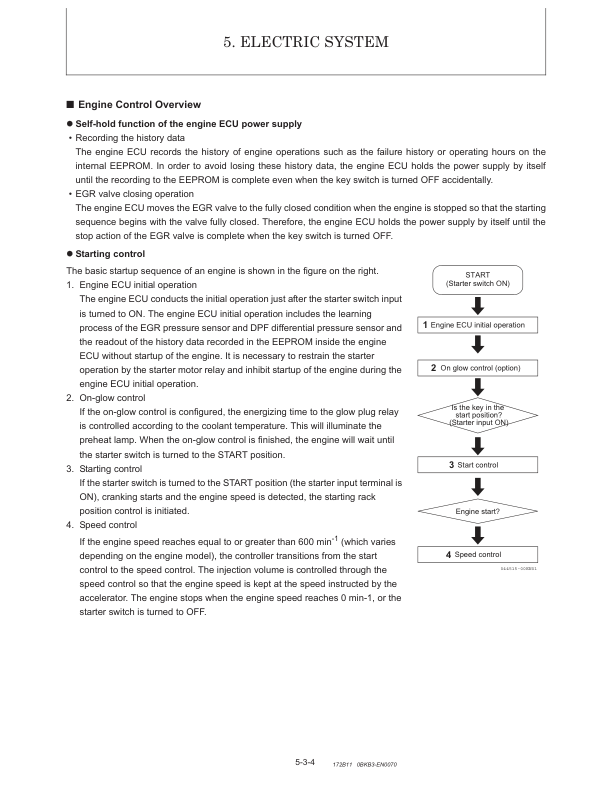

5. Electric System

- Electrical Components Layout: Comprehensive details on the location and function of electrical parts such as LCD monitors and alarms.

- Electronic Controls: Insight into start/stop controls, engine ECU, hydraulic ECU systems, and SMARTASSIST DIRECT (SA-D) features.

- Error Codes: Detailed lists of error codes and compatible diagnostic tools.

6. Hydraulic System

- Circuit Operations: Explanation of hydraulic functions across various systems including the boom, arm, bucket, and others.

- Pump and Valve Maintenance: Guidelines for servicing key hydraulic components like pumps and valves.

- Simultaneous Operations: Insights into complex operations like combined boom and swing activities.

- Troubleshooting: Diagnostic advice for common hydraulic system issues.

7. Adjustment and Repair

- Component Removal and Reinstallation: Guidance on managing the disassembly and reinstallation of critical components such as the engine and cabin.

- Undercarriage Maintenance: Procedures for crawler removal, travel motor servicing, and reassembly of idlers and rollers.

- Hydraulic Cylinder Repair: Detailed steps for disassembling, inspecting, and reassembling hydraulic cylinders.

- Air Conditioning: Instructions for handling removal and reinstallation of air conditioning systems.

8. Troubleshooting

- Non-Breakdown Issues: Solutions for minor operational problems such as bucket release and arm movement irregularities.

- Quick Reference Tables: Quick reference tables for diagnosing and resolving common machine issues efficiently.

Only logged in customers who have purchased this product may leave a review.

Related products

Articulated Loader

$36.00

$36.00

Articulated Loader

$37.00

$33.00

$29.00

Reviews

There are no reviews yet.