Hino Truck FA4J, FB4J Year 2002 Repair Manual (FA, FB)

$36.00

Discover comprehensive maintenance insights with the Hino Truck 2002 Repair and Service Manual, suited for the FA and FB Series.

Format: PDF

Language: English

Hino Truck FA4J, FB4J Year 2002 Repair and Service Manual

Product Overview

This comprehensive repair and service manual is your essential guide for maintaining the 2002 Hino Truck series, including models FA and FB. Designed as a complete resource, this PDF manual is available in English and covers detailed repairs and maintenance protocols to ensure your truck operates smoothly and efficiently for years.

For more information on Hino Trucks, visit the Hino Truck page.

Key Features

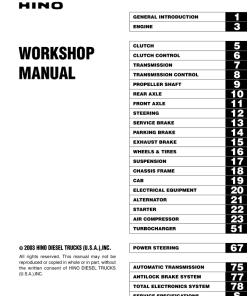

- Detailed manual comprising 1081 pages specific to the Hino 2002 Truck FA and FB Series.

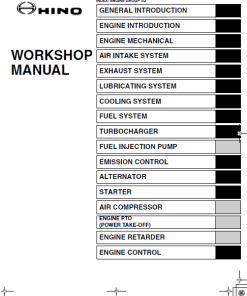

- Comprehensive Hino J05D-TA Engine Manual spanning 324 pages.

- Inclusive Hino J08E-TA & J08E-TB Engine Manuals covering a total of 351 pages.

Benefits

- Provides crucial information to aid in regular maintenance, ensuring safety and economic performance of the vehicle.

- Enables detailed inspection routines to prevent potential issues before they escalate.

- Equips owners with necessary repair procedures while emphasizing safety precautions.

Usage Recommendations

- Owners are encouraged to regularly perform inspections as outlined in the manual.

- Recommended maintenance procedures should be diligently followed to prevent common operational issues.

- Refer to the Owner’s and Driver’s Manual for additional maintenance guidance.

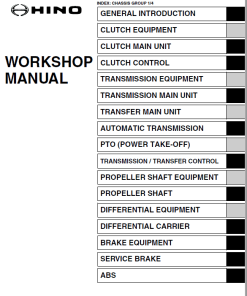

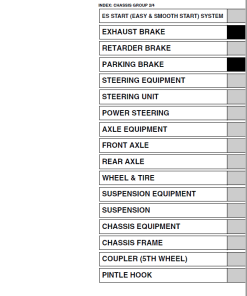

Table of Contents

- General Introduction

- Engine

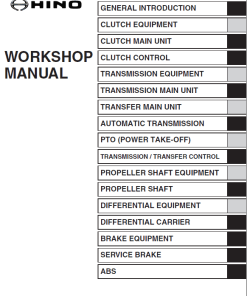

- Clutch and Clutch Control

- Transmission and Transmission Control

- Propeller Shaft, Rear Axle, Front Axle

- Steering and Service Brake Systems

- Parking Brake and Exhaust Brake Systems

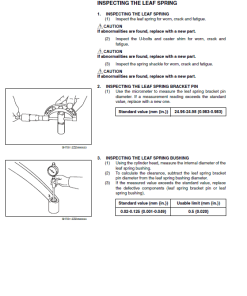

- Wheels, Tires, and Suspension

- Chassis Frame and Cab

- Electrical Equipment including Alternator and Starter

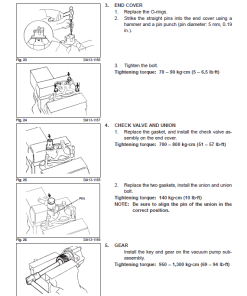

- Compressor, Turbocharger, and Spring Brake Systems

- Power Steering, Automatic Transmission

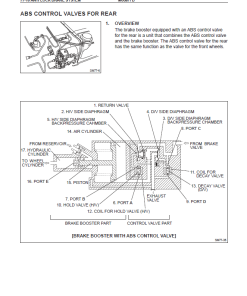

- Antilock Brake System and Total Electronics System

- Service Specification and Electrical Wiring Diagrams

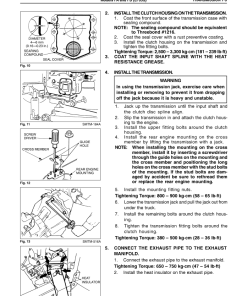

Instruction Extract: Fluid Leak Inspection

To maintain your vehicle’s integrity, regularly inspect for any fluid leakage from gears, pumps, reservoirs, lines, and hoses. Pay extra attention to line joints. If tightening does not resolve leaks, replace or overhaul the affected parts.

Note: Promptly addressing fluid leaks prevents a drop in fluid levels, which could lead to serious damage such as power steering malfunction or pump jamming.

- Fluid leakage from the power steering gear:

- Inspect areas such as worm shaft, end plug, sector shaft, and adjuster screw for leaks.

- Note: Replace the entire kit when changing the worm shaft oil seal.

- Fluid leakage from the pump and tank:

- Check seals for leaks and replace the entire seal kit if needed.

- Fluid leakage from lines:

- Inspect line joints and hose end joints for leaks.

- Actions if leaks are detected:

- Tighten the nut or hose clamp.

- Replace lines if damage or corrosion is evident.

- Replace hoses if any damage or cracks are present.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.