Hitachi ZX240-5A, ZX240LC-5A and ZX250LCH-5A Excavator Repair Manual

$36.00

This comprehensive manual covers the following Hitachi Excavator models:

- ZX240-5A

- ZX240LC-5A

- ZX250H-5A

- ZX250LCH-5A

- ZX250K-5A

- ZX250LCK-5A

Format: PDF

Language: English

The Hitachi Excavator Service Repair Manual provides detailed maintenance and repair instructions. See the description for more details.

Hitachi ZAXIS Excavator Manual for Models ZX240-5A, ZX240LC-5A, and ZX250LCH-5A

Product Overview

This manual is designed for the Hitachi ZAXIS Excavator models:

- ZX240-5A

- ZX240LC-5A

- ZX250H-5A

- ZX250LCH-5A

- ZX250K-5A

- ZX250LCK-5A

Format: PDF

Language: English

The manual includes comprehensive directives for effective operation, troubleshooting, and maintenance of these models, comprising:

- Service Manual (Troubleshooting): Volume No. TODCY90-EN (470 Pages)

- Service Manual (Operation): Volume No. TTDCY90-EN (387 Pages)

- Workshop Manual: Volume No. WDCY90-EN (516 Pages)

- Circuit Diagram: 15 Pages

All measurements are provided in SI Units (International System of Units).

Key Features

- Detailed operational guides and performance tests

- Comprehensive troubleshooting procedures

- Step-by-step maintenance and repair instructions

- Circuit diagrams for troubleshooting and repairs

Benefits

- Improves efficiency with reduced downtime through detailed troubleshooting

- Ensures optimal operation with enhanced guidelines

- Facilitates safe maintenance practices through accurate technical data

- Promotes cost-effective operations with fuel-efficient practices

Usage Recommendations

- Refer to the manual before conducting any repair or maintenance tasks to ensure safety.

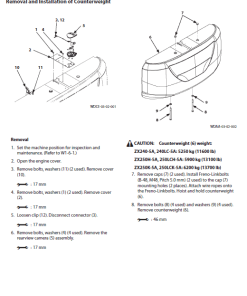

- Utilize appropriate lifting techniques and equipment to prevent injury when handling heavy components.

- Regularly consult the manual for operational procedures to maximize machine durability and performance.

The Hitachi ZAXIS series boasts industry-leading hydraulic technology, promising unmatched performance. With its advanced hydraulic systems and engines, the ZAXIS series guarantees superior fuel efficiency, quick movement response, and easy operationu2014characteristics that define its superb quality, low operational cost, and exceptional durability. These machines are engineered to fulfill your aspirations while pioneering advancements for your future.

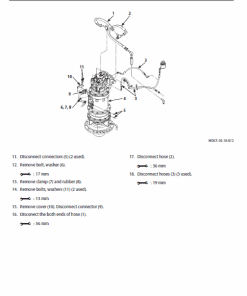

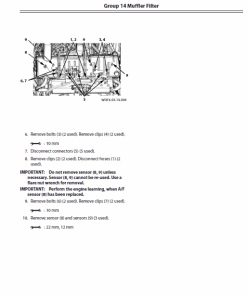

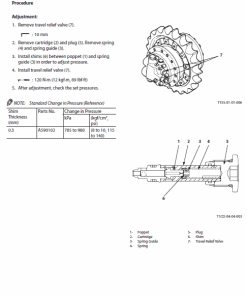

Flow Combiner Valve Manual Instructions Extract:

/p>

1. During combined operations, pilot pressures manage travel and arm spool movements.

2. The control spool is aligned by the pilot pressure, directing oil to designated ports.

3. Oil flow triggers spool movements, enabling controlled travel and arm actions.

4. Equal oil distribution ensures balanced and straight machine movement.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.