Hitachi ZX250LC-6 and ZX250LCN-6 ZAXIS Excavator Repair Manual

$35.00

This comprehensive service repair manual is tailored for the Hitachi Excavator models ZX250LC-6 and ZX250LCN-6.

Format: PDF

Language: English

The manual includes the following volumes:

Hitachi ZX250LC-6 and ZX250LCN-6 ZAXIS Excavator Manual

Product Overview

The comprehensive manual for the Hitachi Excavator models ZX250LC-6 and ZX250LCN-6 offers detailed guidance in PDF format. It is a vital resource for operators and technicians, encompassing crucial aspects of maintenance, troubleshooting, and operation.

Language: English

Manual Components

For the ZAXIS ZX250LC-6 and ZX250LCN-6 models, the manual collection includes:

- Service Manual (Troubleshooting): Vol. No. TODC150-EN (540 Pages)

- Service Manual (Operation): Vol. No. TTDC150-EN (472 Pages)

- Workshop Manual: Vol. No. WDC150-EN (661 Pages)

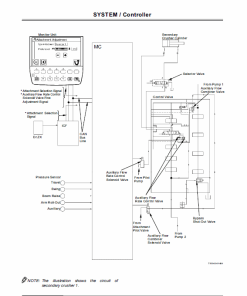

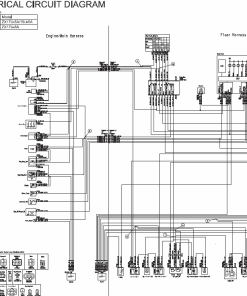

- Circuit Diagram: 15 Pages

The manual utilizes SI Units (International System of Units) for measurements.

Key Features

- Service Manual: Includes technical information for redelivery, operation, device activation, performance tests, and troubleshooting procedures.

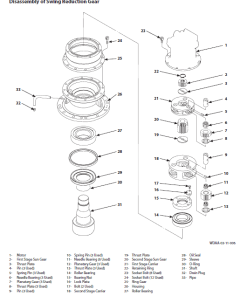

- Workshop Manual: Offers guidance for maintenance and repair, required tools and devices, maintenance standards, and removal/installation procedures.

Benefits

- Improves safety and efficiency in handling and maintenance.

- Provides detailed instructions to avoid injuries and equipment damage.

- Supports the optimization of hydraulic systems and engine performance.

- Ensures low running costs with high quality, low fuel consumption, and enhanced durability.

Usage Recommendations

- Refer to the service manual before operating the machine to avoid injury and damage.

- Utilize appropriate lifting techniques and equipment for handling heavy parts.

Additional Information

The ZAXIS series is renowned for its industry-leading hydraulic technologies and unmatched performance, featuring impressive fuel economy and ease of operation. This manual offers insights into the advanced hydraulic systems and engine optimizations developed by Hitachi, aiming to realize customer visions and set the path for innovation.

Relief Valve Manual Instructions Extract

Low-Pressure Relief Operation (Shockless Function):

- Pressure at port HP is routed to oil chamber C through orifice.

- Oil flows to chambers A and B, with chamber B providing greater pressure on the piston.

- As the piston moves, pressure is relieved via the orifice, activating the poppet valve.

- Once the piston reaches the stroke’s end, pressure equalizes, closing the poppet valve.

High-Pressure Relief Operation (Overload Prevention):

- Normal relief set pressure is achieved after the piston stroke ends.

- Excess pressure at port HP opens the poppet valve, releasing pressure.

- Pressure normalization at port HP closes the valve.

/p>

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.