Hitachi ZX70 Excavator Service Repair Manual

$36.00

Enhance your repair and maintenance procedures with our comprehensive manual set. This set includes:

- Troubleshooting Manual: 322 Pages

- Operation Manual: 192 Pages

- Workshop Manual: 608 Pages

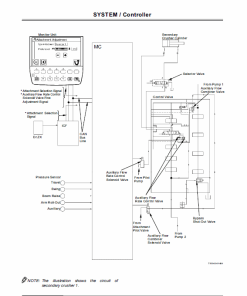

- Circuit Diagram: 6 Pages

- Parts Catalog: 644 Pages

Designed for professionals, these manuals provide detailed guidance and valuable insights to keep your operations running smoothly.

Hitachi ZX70 Excavator Service Manual

Product Overview

The Hitachi ZX70 Excavator Service Manual is a comprehensive resource designed for the ZX70 excavator model. Available in PDF format, this manual is your go-to guide for troubleshooting, operations, maintenance, and detailed understanding of the ZX70 components. The content is presented in English.

For more information about the model, visit the Excavator Model page.

Contents

The manual provides detailed information across multiple sections:

- Troubleshooting Manual: 322 pages

- Operation Manual: 192 pages

- Workshop Manual: 608 pages

- Circuit Diagram: 6 pages

- Parts Catalog: 644 pages

Key Features

- Comprehensive Guide: Offers technical information required for redelivery, delivery, operation, activation of systems, performance tests, and troubleshooting.

- Maintenance and Repair: Includes tools and methods needed for maintenance and repair, standards, and procedures for disassembly and reassembly.

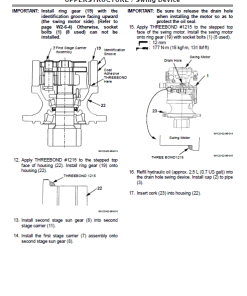

Workshop Manual Overview

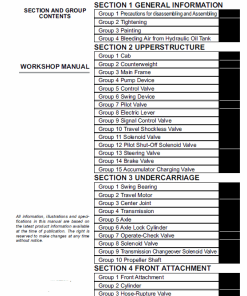

The Workshop Manual is divided into several sections, covering essential components:

- General:

- Precautions for Disassembling and Assembling

- Tightening Torque

- Painting

- Bleeding Air from Hydraulic Oil Tank

- Upperstructure:

- Cab

- Counterweight

- Main Frame

- Pump Device

- Control Valve

- Swing Device

- Pilot Valve

- Pilot Shut-Off Valve

- Undercarriage:

- Swing Bearing

- Travel Device

- Center Joint

- Track Adjuster

- Front Idler

- Upper and Lower Roller

- Track

- Front Attachment:

- Front Attachment

- Cylinder

- Holding Valve

- Engine:

Usage Recommendations

- Utilize the manual for both operational and maintenance purposes to ensure the longevity and efficiency of the excavator.

- Regularly consult the troubleshooting section to address any technical issues promptly.

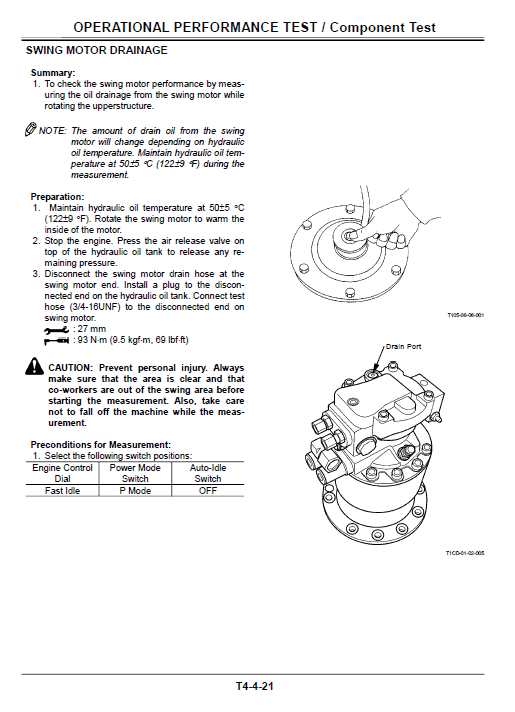

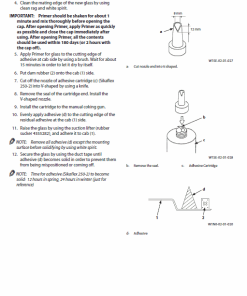

Swing Bearing Play Check

Purpose: Verify the wear on the swing bearing races and balls by measuring play between the outer and inner races.

Preparation Steps:

- Inspect mounting bolts for looseness on the swing bearing.

- Ensure smooth rotation and proper lubrication of the swing bearing.

- Install a dial gauge with a magnetic base on the upper side of the track frame.

- Align the upper structure so the boom faces towards the front idlers.

- Position the dial gauge to contact the center of the bearing’s outer race bottom face.

- Ensure the bucket is empty before proceeding.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.