Hyundai R220LS (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00

Hyundai R220LS (Smart+) Crawler Excavator Manuals

Explore the comprehensive manuals for the Hyundai R220LS (Smart+) Crawler Excavator, engineered for optimal performance.

Language: English

Format: PDF

Hyundai R220LS (Smart+) Crawler Excavator Service and Repair Manual

Product Overview

The Hyundai R220LS (Smart+) Crawler Excavator Service and Repair Manual, designed for models built in India, serves as an essential resource for technical understanding and accurate repair work. This manual is crafted to assist service professionals by providing detailed instructions and insights necessary to maintain and enhance the operational efficiency of the excavator.

View more details about the Crawler Excavator Model R220LS (Smart+)

Language: English

Format: PDF

Included Manuals

- Service Repair Manual – 565 Pages

- Operators Manual – 159 Pages

Key Features

- Comprehensive guide covering 565 pages of service repair instructions.

- Contains 159 pages of operator-focused guidance for optimal usage.

- Detailed mechanical, electrical, and mechatronics systems descriptions.

Benefits

- Improve repair quality by understanding the product thoroughly.

- Access to step-by-step procedures for maintaining and servicing equipment.

- Utilize troubleshooting tips to diagnose and rectify common issues efficiently.

Usage Recommendations

- Ideal for service technicians and workshop professionals responsible for maintenance.

- Reference regularly to ensure the correct execution of repair tasks and safety protocols.

- Leverage as an educational resource for understanding complex system interactions.

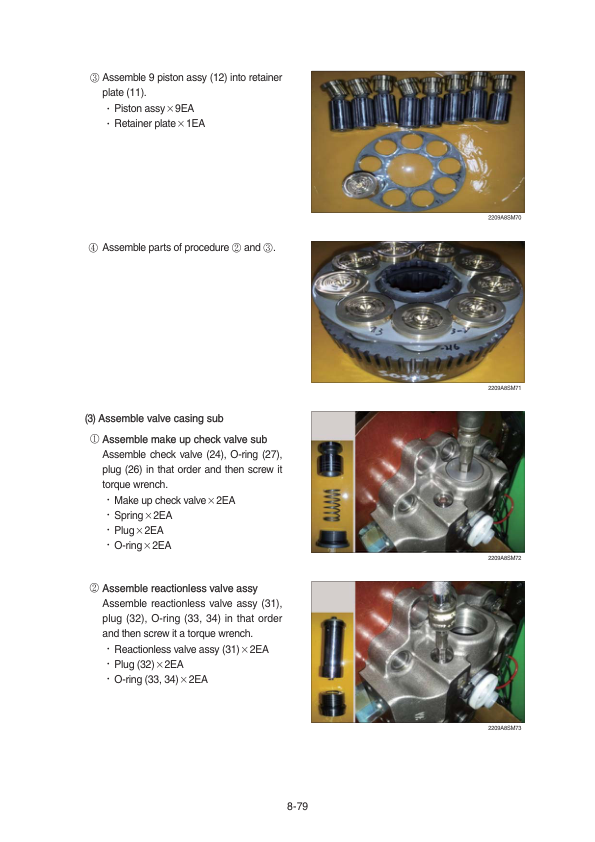

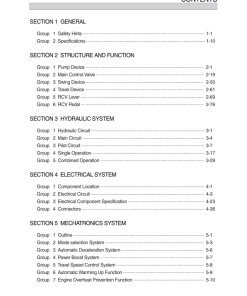

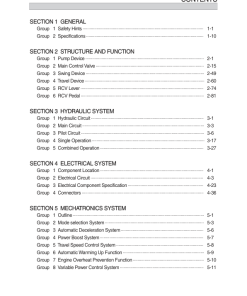

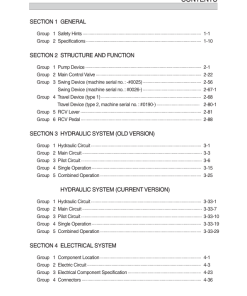

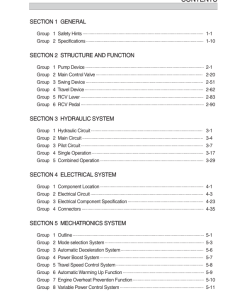

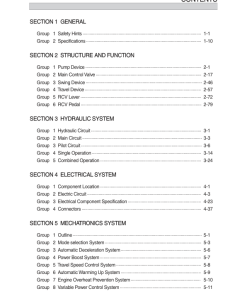

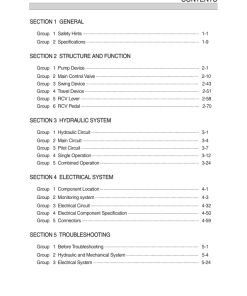

Table of Contents

FOREWORD

GENERAL

1. Safety hints

2. Specifications

STRUCTURE AND FUNCTION

1. Pump device

2. Main control valve

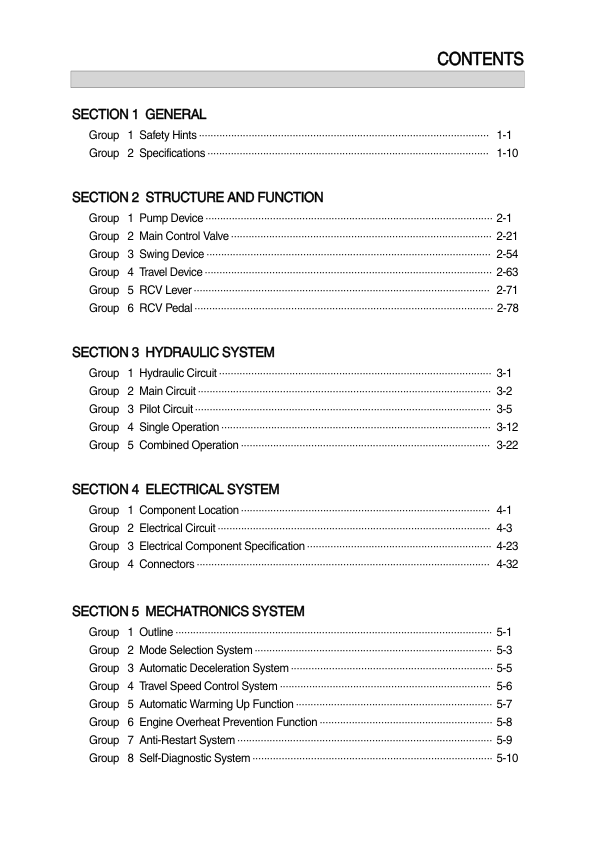

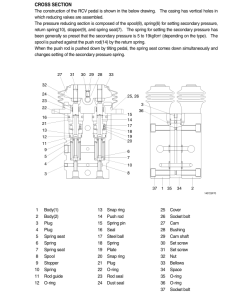

3. Swing device

4. Travel device

5. RCV Lever

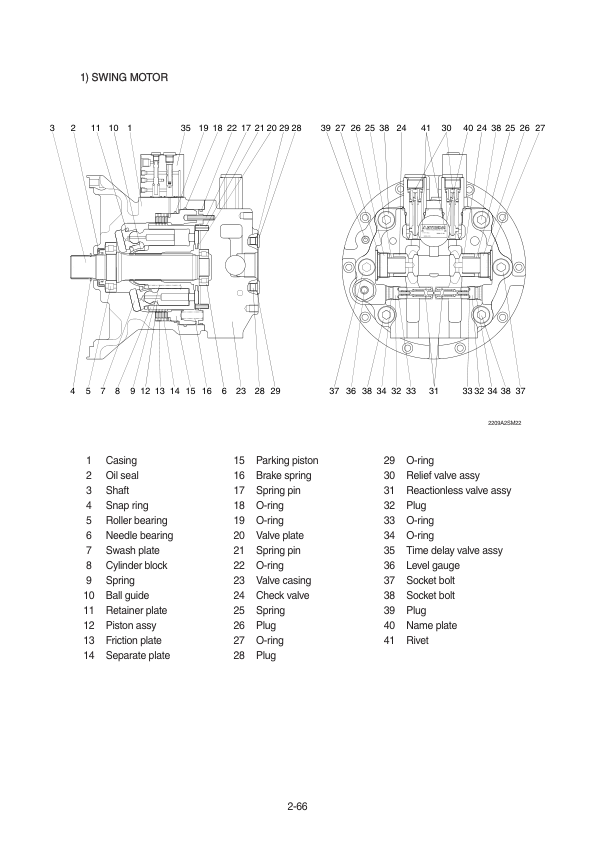

6. RCV pedal

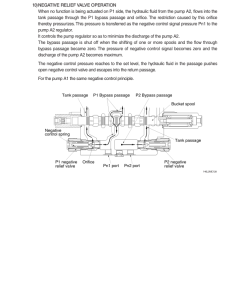

HYDRAULIC SYSTEM

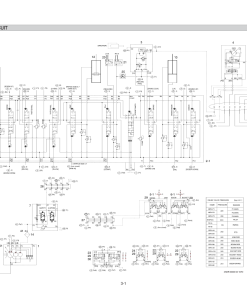

1. Hydraulic circuit

2. Main circuit

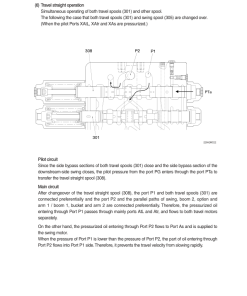

3. Pilot circuit

4. Single operation

5. Combined operation

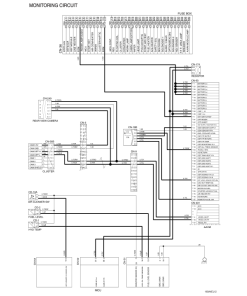

ELECTRICAL SYSTEM

1. Component location

2. Electric circuit

3. Electrical component specification

4. Connectors

MECHATRONICS SYSTEM

1. Outline

2. Mode selection system

3. Automatic deceleration system

4. Power boost system

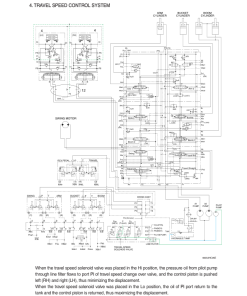

5. Travel speed control system

6. Automatic warming up system

7. Engine overheat prevention system

8. Variable power control system

9. Attachment flow control system

10. Anti-restart system

11. Self-diagnostic system

12. Engine control system

13. EPPR valve

14. Monitoring system

15. Fuel warmer system

TROUBLESHOOTING

1. Before troubleshooting

2. Hydraulic and mechanical system

3. Electrical system

4. Mechatronics system

MAINTENANCE STANDARD

1. Operational performance test

2. Major components

3. Track and work equipment

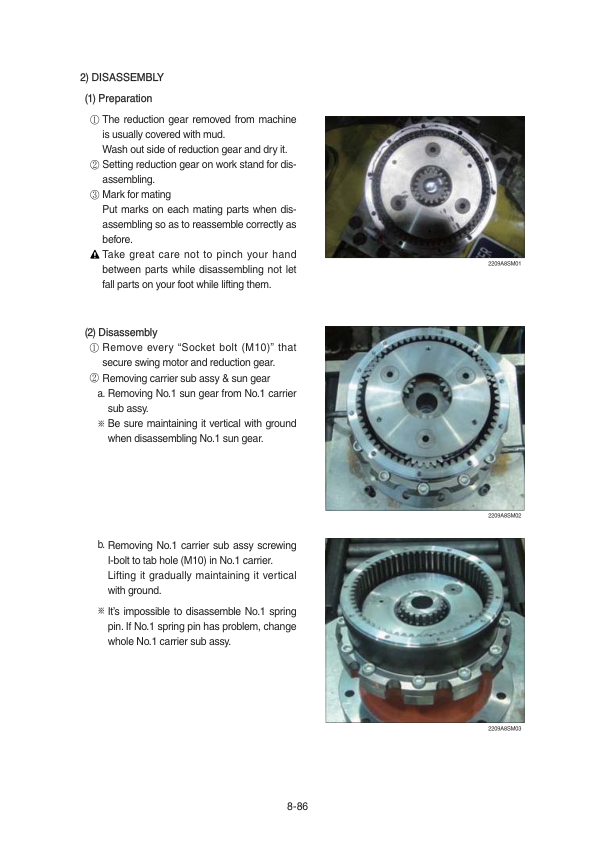

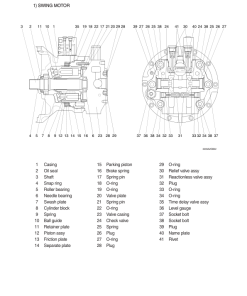

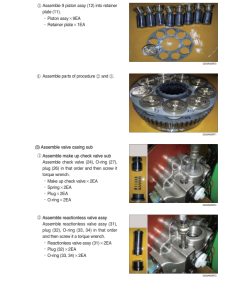

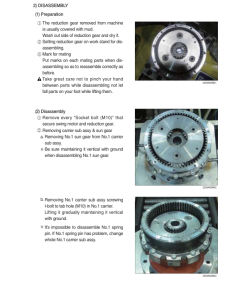

DISASSEMBLY AND ASSEMBLY

1. Precaution

2. Tightening torque

3. Pump device

4. Main control valve

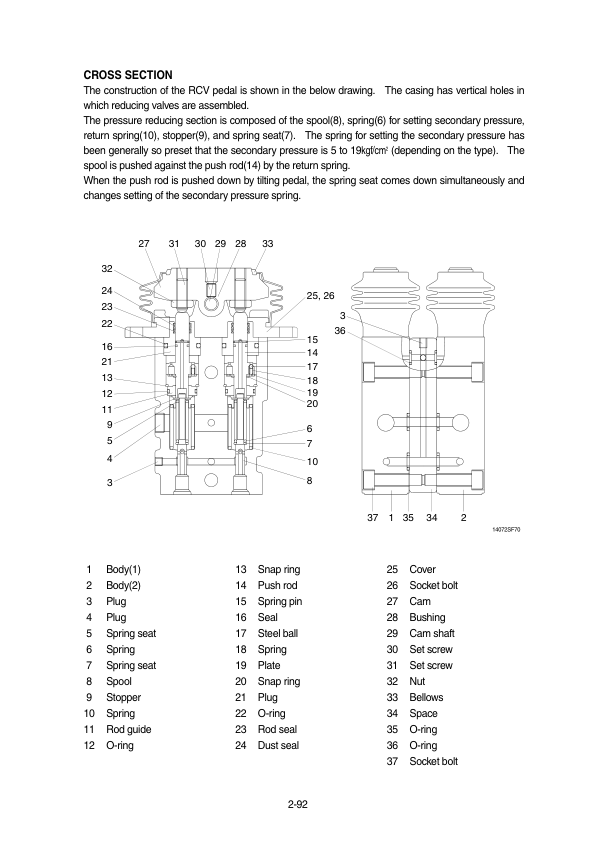

5. Swing device

6. Travel device

7. RCV lever

8. Turning joint

9. Boom, arm and bucket cylinder

10. Undercarriage

11. Work equipment

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.