Kawasaki 65ZIII Wheel Loader Service Manual

$34.00

Discover comprehensive resources for your Kawasaki Wheel Loader. Available in English, these manuals offer detailed guidance:

Format: PDF

Repair Service Manual: 360 pages of in-depth instructions for maintaining and repairing your Kawasaki 65ZIII Wheel Loader.

Parts Catalog Manual: A concise 50-page guide to all necessary parts for the 65ZIII model.

Kawasaki 65ZIII Wheel Loader Service Manual

Product Overview

The Kawasaki 65ZIII Wheel Loader Service Manual is a comprehensive guide designed for the maintenance and repair of the Kawasaki 65ZIII or 65Z3 Wheel Loader. This manual is meticulously crafted to provide clear and concise instructions to ensure reliable, long-term service of your machinery. The manual is available in English and presented in PDF format for ease of use.

Comprising a total of 360 pages, the service manual details repair and maintenance procedures, while the 50-page parts catalog manual provides an in-depth look at the components of the wheel loader.

Manual Details

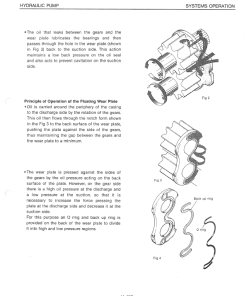

This service manual includes the latest guidelines, illustrations, and photographs to facilitate effective repair and maintenance operations. It is structured logically to enable users to execute maintenance tasks systematically for optimal loader performance.

Important safety-related maintenance operations are clearly marked within the manual, ensuring maximum safety during the execution of tasks.

Key Features

- General Outline

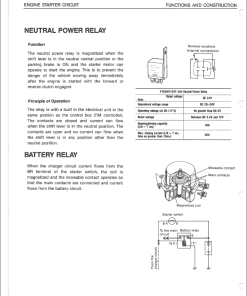

- Functions and Construction

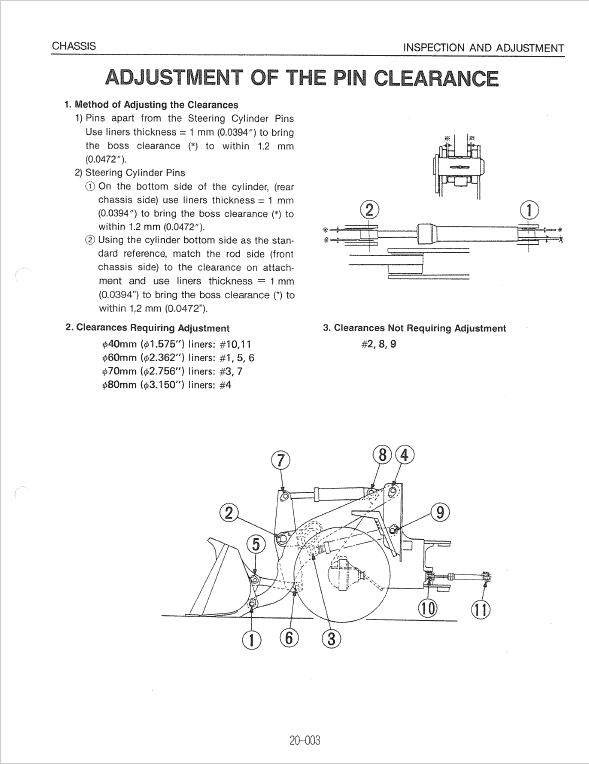

- Inspection and Adjustment

- Disassembly and Assembly

- Standard Values

Benefits

- Ensures detailed and clear instructions for maintenance.

- Keeps your machinery operating efficiently with routine checks.

- Enhances safety through marked safety-related operations.

- Accessible format for easy reference and use.

Usage Recommendations

- Thoroughly read and understand the manual before attempting any repair or maintenance tasks.

- Follow the systematic approach outlined for maintenance work to avoid damage and ensure safety.

- Refer to the marked sections for critical safety operations.

Manual Extract

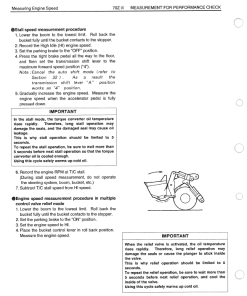

Main-line-pressure Drop to Reduce Shock at Clutch Engagement:

The manual explains that the main pressure drops due to oil flow into an empty reverse clutch piston chamber. Additionally, a small amount of oil drains through a residual-pressure prevention orifice within the chamber.

As the oil pressure in the modulator chamber decreases, oil is discharged over the check valve, causing the modulator piston to move. The right-side spring force exceeds the left-side oil pressure, leading to rapid oil drainage through the drain port when the drain piston resets.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.