Kawasaki 90ZIV Wheel Loader Service Manual

Product Overview

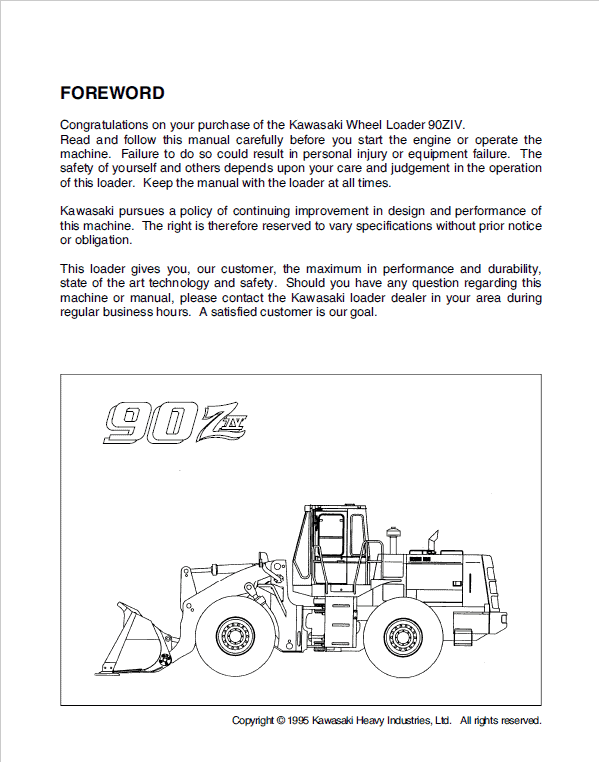

The Kawasaki 90ZIV Wheel Loader Service Manual is an essential resource for anyone responsible for maintaining or repairing the Kawasaki 90ZIV or 90Z4 wheel loader. The manual is comprehensive and user-friendly, offering detailed instruction in English and available in PDF format.

This service manual, complete with 946 pages of in-depth content, is accompanied by a 162-page Operating (Owner’s) Manual and a 136-page Parts Catalog, ensuring a thorough understanding of both operational and repair principles.

Manual Details

The manual provides systematic and logical approaches to conducting maintenance and repair activities, emphasizing the importance of following the guidelines to ensure optimum long-term performance of your wheel loader. Highlighted with safety indicators, the manual equips you with critical insights needed for safe and efficient operations.

Key Features

- Includes comprehensive drawings and photographs relevant at the time of publication.

- Structured content for ease of use and navigation.

- Contains the following sections:

- 01 General Outline

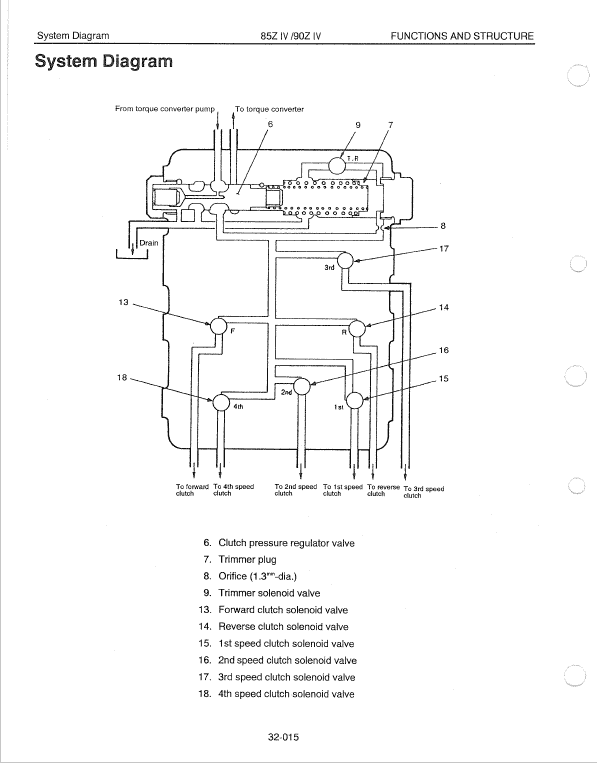

- 10 Functions and Construction

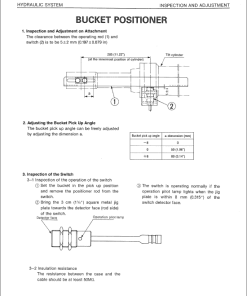

- 20 Inspection and Adjustment

- 30 Disassembly and Assembly

- 40 Maintenance Standards

Benefits

- Ensures reliable, long-term service by adhering to prescribed maintenance protocols.

- Emphasizes crucial safety operations through marked sections, enhancing operational safety.

- Maximizes operational efficiency by providing detailed repair and maintenance guidance.

Usage Recommendations

- Systematically follow the manual for conducting maintenance work to avoid unexpected failures.

- Utilize the manual’s marked safety sections as primary guidelines for maintaining safe operation.

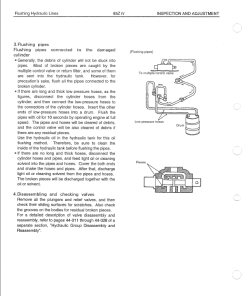

- Refer to the manual for detailed inspections, adjustments, disassembly, and assembly procedures.

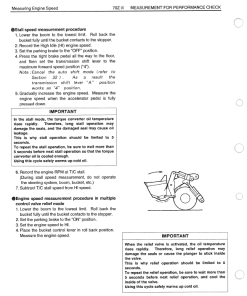

Operation of Torque Converter

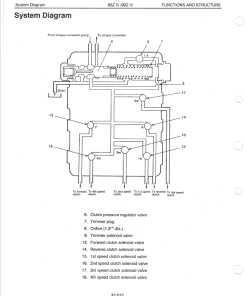

n Positioned between the engine and transmission, the torque converter consists of three key components: pump (P), turbine (T), and stator (S) impellers. The pump impeller, mounted to the engine flywheel, rotates with the engine, moving oil to drive the turbine impeller, which connects to the torque converter’s output shaft and transmits power to the transmission.

Through this operation, oil is redirected by the fixed stator back to the pump, facilitating continued rotation of the turbine. A decrease in turbine speed while maintaining pump speed results in increased output torque, known as “torque multiplication”, a process which also generates heat.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.