Kobelco K907-II and K907LC-II Excavator Service Manual

$34.00

Enhance your understanding of the Kobelco K907-II and K907LC-II Excavators with this comprehensive technical manual. Available for download in PDF format, this manual is published in English and contains detailed information across 572 pages.

Access the manual here: Excavator.

Publication ID: S5YN0001E02

Kobelco K907-II and K907LC-II Excavator Service Manual

Product Overview

Access comprehensive support for your Kobelco K907-II and K907LC-II Excavators with this detailed service manual, formatted as a downloadable PDF. Written in English, this manual spans 572 pages, providing extensive technical information critical for maintenance and repairs.

Publication Number: S5YN0001E02

Key Features

- Format: PDF

- Language: English

- Extensive 572-page manual

- Complete table of contents including Specifications, Maintenance, System Overview, Disassembling Techniques, and Troubleshooting Procedures

Benefits

- Provides thorough guidance for repair specialists working on Kobelco excavators.

- Includes critical safety instructions to ensure safe operation and maintenance.

- Acts as a valuable reference for both seasoned and new mechanics unfamiliar with specific systems.

- Facilitates accurate and effective problem solving with a detailed troubleshooting section.

Usage Recommendations

- Always read and comprehend all warning labels and decals before operating or servicing the machine.

- Consult the manual systematically before starting any repair work to ensure correct procedures, especially for lifting components and handling pressured fluids.

- Employ the manual as a constant reference, enhancing the efficiency and safety of repair operations.

Technical Instructions

The Kobelco K907-II and K907LC-II Preface Instructions

This manual has been crafted for repair specialists. It is vital that servicemen and mechanics, who might not be familiar with all the systems, use this manual diligently. Particular attention should be given when performing service tasks to avoid hazards and ensure correct procedures.

Carefully navigate through the Excavator Shop Manual before any repair tasks. Proper lifting techniques must be utilized when removing components. Exercise caution when handling filler caps, breathers, and plugs to avoid contact with hot or pressurized fluids, especially after machine operation.

Even seasoned mechanics will find the Workshop Manual beneficial as a reference source, aiding in thoroughly executed repairs.

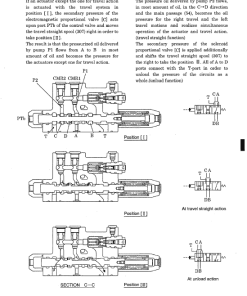

Relay System

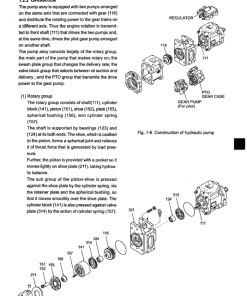

The four-electrode relay system is critical for controlling the blower OFF and compressor functions:

- Blower OFF Relay: Activates upon receiving a signal from the control amplifier, supplying voltage to the blower motor to initiate operation.

- Compressor Relay: Controlled by the amplifier and electronic thermostat, this relay manages the operation of the compressor.

Relay Inspecting Items:

- Relay Type: 24-4PE

- Coil Resistance: 320 ohms

- Specified Voltage: DC20V to DC30V

- Note: Be mindful of the relay coil’s polarity during inspection to ensure proper functionality.

- Inspection Method: Check continuity between terminals 3 and 4 under specified voltage conditions:

- 20V-30V applied between terminals 1-2: Continuity confirmed

- 20V-30V not applied between terminals 1-2: No continuity

Only logged in customers who have purchased this product may leave a review.

Related products

Excavator

Reviews

There are no reviews yet.