Kobelco SK100-III Excavator Service Manual

$34.00

Explore the comprehensive Kobelco SK100-III Excavator Technical Manual available in PDF format. This detailed manual is your guide to understanding every aspect of the SK100-III model. It spans 760 pages and is published under the code S5YW0002E-00. Available in English, it is an essential resource for users and technicians.

Access the manual here: Excavator SK100-III

Kobelco SK100-III Excavator Service Manual

Product Overview

The Kobelco SK100-III Excavator Service Manual is an essential PDF document, consisting of 760 pages, meticulously crafted to support repair specialists. Written in English and denoted as Publication S5YW0002E-00, this manual provides comprehensive guidance on the maintenance and repair of the SK100-III Excavator.

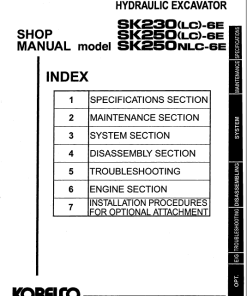

Table of Contents

- General

- System

- Components

- Procedures

Preface Instructions

Prior to operating, maintaining, or repairing the machine, please read and understand all warning signs and decals on the equipment. This manual is specifically designed for repair specialists who may be unfamiliar with the various systems of the Kobelco SK100-III Excavator. Carefully adhere to the instructions outlined within to safely and efficiently carry out service work.

Review the Shop Manual thoroughly before initiating any repair tasks. Employ appropriate lifting techniques when dismantling components, and exercise caution when handling filler caps, breathers, and plugs to prevent injury from pressurized fluids. Exercise extra caution with hot fluids if the machine was recently in use.

Use the Service Manual as an information source, even for those experienced with excavator technology. It serves as a valuable reference for successfully completing essential repairs.

Key Features

- Detailed guidance for repair specialists.

- Step-by-step instructions for maintenance and repair.

- Comprehensive indexing for easy navigation.

Benefits

- Reduces repair costs by enabling timely maintenance.

- Increases excavator availability and operational efficiency.

- Ensures safety by preventing improper machine operation.

Usage Recommendations

- Always refer to the service manual before commencing any work.

- Follow specified instructions to prevent accidents or equipment damage.

- Perform repairs promptly to minimize downtime and costs.

Repair and Maintenance Insights

It is crucial to execute necessary repairs at the earliest opportunity to minimize costs and boost the machine’s availability. Adhere strictly to the manual’s guidelines to ensure safe operation. Never operate the machinery without thoroughly understanding the service instructions, as improper operation poses serious risks, including injury or fatality.

Installing and Removing the Swing Ring

n Instructions:

1. Remove the upper frame from the machine (consult the “Upper Frame” manual).

2. Detach the capscrews securing the inner race to the swing bearing.

3. Attach lifting rings to the swing bearing and lift using a crane until it disengages.

4. Preparing for installation, cleanse dust and oil from the swing ring and lower frame’s surfaces.

5. Position the swing ring so the “S” mark on the inner race faces the machine’s left-hand side.

6. Apply Three Bond 1305 to capscrew threads and hand-tighten.

7. Temporarily tighten diagonally opposite capscrews to 15kgfu00b7m (108 ft-lbs).

8. Finally, secure all capscrews to a torque of 28.5kgfu00b7m (206 ft-lbs).

“, “

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.