Kobelco SK13SR Excavator Service Manual

$34.00

Access the comprehensive technical guide for the Kobelco SK13SR Excavator. This manual is available in PDF format and written in English, featuring 478 pages of detailed information. The publication code is S5PE0001E-01.

Kobelco SK13SR Excavator Service Manual

Product Overview

The Kobelco SK13SR Excavator Service Manual is an essential resource designed for repair specialists and mechanics who need detailed instructions for the repair and maintenance of the SK13SR Excavator. This comprehensive manual, published as document S5PE0001E-01, spans 478 pages and is available in PDF format in English.

Key Features

- Format: PDF

- Language: English

- Total Pages: 478

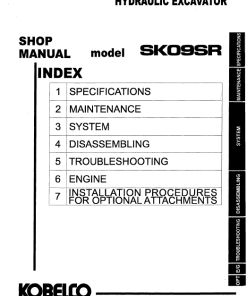

Table of Contents

- Specifications

- Maintenance

- System

- Disassembling

- Troubleshooting

- Engine

- Installation Procedures for Optional Attachments

Benefits

- Provides detailed instructions and insights specific to the SK13SR model, facilitating expert repairs.

- Helps improve mechanical understanding and safety precautions necessary for operating and repairing the excavator.

- Reduces repair costs and downtime by ensuring maintenance and repair tasks are performed proficiently.

Usage Recommendations

- Always read and understand all warning plates and decals on the machine prior to operation, maintenance, or repairs.

- Use the manual as a reference even if you are experienced with excavator technology; it offers valuable insights into specific systems.

- Follow all cautionary guidelines and use proper lifting procedures when dismantling components.

- Be cautious of pressurized liquids, especially immediately after the machine has been used, to prevent burn injuries.

The SK13SR Excavator u2013 Preface Instructions

Before operating, maintaining, or repairing the Kobelco SK13SR Excavator, it is crucial to thoroughly review all warning signs and instructions. The manual provides the necessary guidance and safety precautions needed to execute service tasks safely and efficiently.

Repair and Parts Guidance

Ensure repairs are executed promptly to minimize costs and maximize the excavator’s availability. Adhere to the guidelines provided in the service manual, as improper machine handling can lead to serious injuries or accidents.

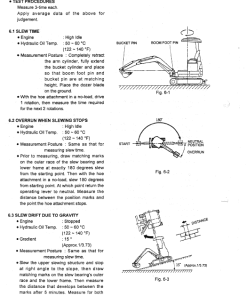

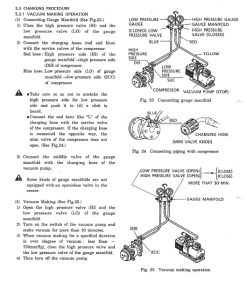

Drain Rate of Travel Motor Procedure

Preparation

1. Stop the engine and release air from the hydraulic oil tank.

2. Disconnect the slew motor drain hose from the return side to the hydraulic oil tank, then collect the drain oil in a container.

3. After removing the drain hose, install a plug on the tank bore.

Measurement

– Perform with the engine at rated speed and hydraulic oil temperature between 50 ~ 60u00b0C (122 ~ 140u00b0F).

– Set the machine posture by pushing the fixture with the bucket side and operating the engine.

– Measure the drained oil volume for 30 seconds while relieving the full stroke of the slewing operation.

Only logged in customers who have purchased this product may leave a review.

Related products

Excavator

Excavator

Reviews

There are no reviews yet.