Kobelco SK210LC, SK250LC Excavator Service Manual

$36.00

Access the detailed manual for the Kobelco Excavator SK210LC and SK250LC. This comprehensive guide is presented in PDF format and available in English. The publication reference is S5YQ/LL12E-00, encompassing a total of 1052 pages of essential technical information.

Kobelco SK210LC, SK250LC Excavator Service Manual

Product Overview

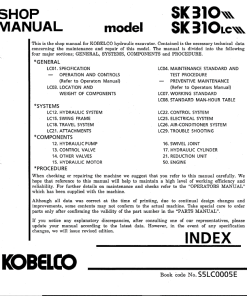

The Kobelco SK210LC, SK250LC Excavator Service Manual is an essential resource for repair specialists working with these specific excavator models. This comprehensive manual, written in English and published under S5YQ/LL12E-00, comprises 1052 pages formatted in PDF. It is indispensable for those needing detailed information and guidance on the repair and maintenance of these machines.

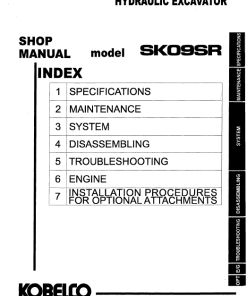

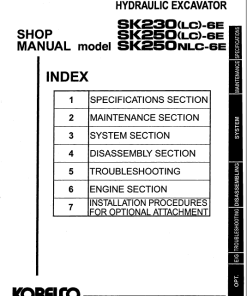

Table of Contents

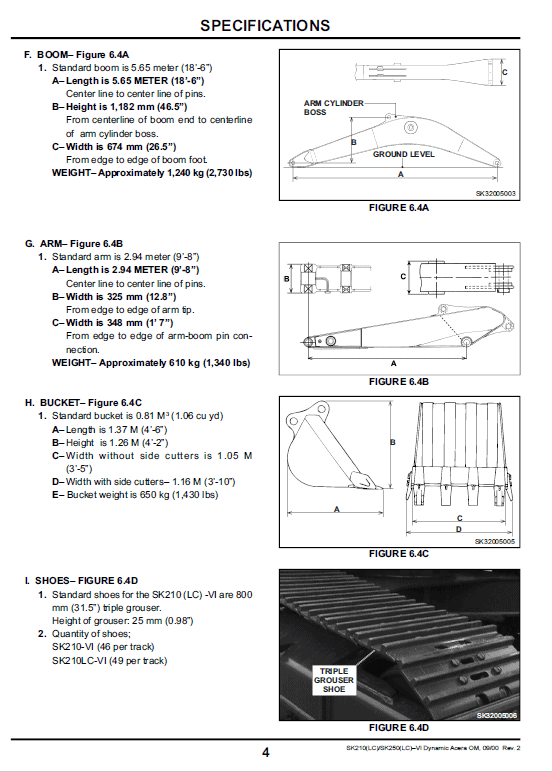

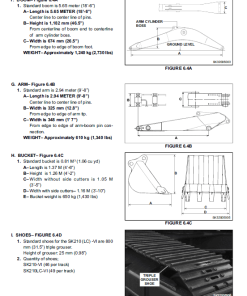

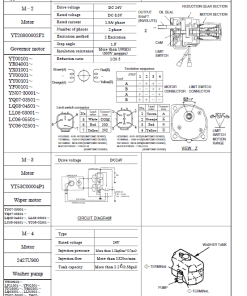

- Section 1 – Specification

- Section 2 – Maintenance

- Section 3 – System

- Section 4 – Disassembly

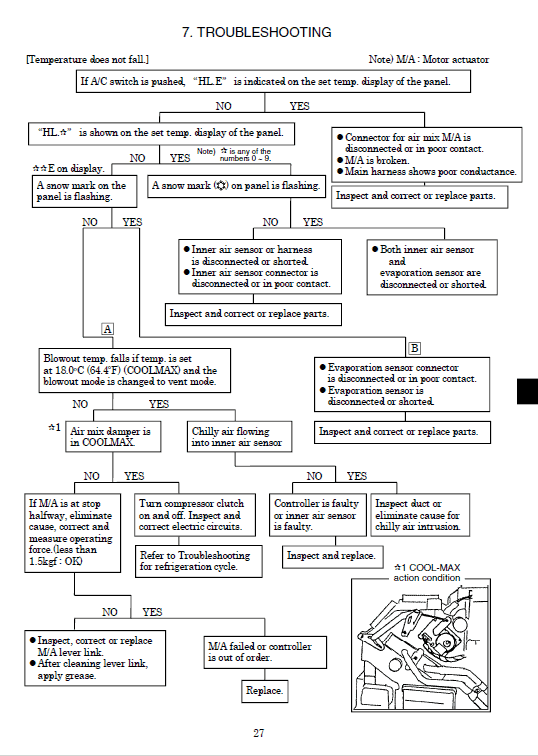

- Section 5 – Troubleshooting

- Section 6 – Engine

- Section 7 – Miscellaneous

Preface Instructions

Prior to operating, maintaining, or repairing the SK210LC and SK250LC excavators, ensure to thoroughly read and understand all warning plates and decals on the machine. The manual is crafted for repair specialists who may not be familiar with the machine’s various systems. Caution and adherence to this manual are critical when conducting service work.

It is crucial to familiarize yourself with the Shop Manual before beginning any repair tasks. Always utilize proper lifting techniques and exercise caution when removing filler caps, breathers, and plugs to prevent exposure to pressurized fluids, which may be hot if the machine has been recently operated.

Even for experienced construction machine mechanics, the Shop/Service Manual serves as a valuable reference for performing necessary repairs efficiently and safely.

Sections of the Manual

The manual is organized into sections, indexed for easy navigation. Each section can be accessed quickly via the margin indexes, allowing for efficient troubleshooting and maintenance procedures.

Repair and Parts

Timely repair work reduces costs and improves the availability of your excavator. Always follow the instructions in the Service Manual to safely operate and maintain the machine, thereby avoiding any hazardous situations that could lead to injury or death.

Usage Recommendations

Refueling

- Move to a well-ventilated area when refueling.

- Use only the specified fuel mentioned in the Maintenance section of the operator’s manual.

- Clean up any spilled fuel immediately and tighten the fuel cap securely after refueling.

Hydraulic Pressure

- Under standard conditions, hydraulic systems are under high pressure. Use a piece of cardboard, wood, or metal to detect leaks.

- Avoid contact with any leaked hydraulic fluid as pinhole leaks can be dangerous.

- Wear approved safety gear, including safety glasses, gloves, and appropriate work attire during inspections.

Only logged in customers who have purchased this product may leave a review.

Related products

Excavator

Reviews

There are no reviews yet.