Engine Maintenance Manual

Product Overview

This comprehensive manual provides detailed guidance on the maintenance and repair of engine systems. It covers essential procedures and standards, ensuring effective troubleshooting, inspection, and adjustment of engine components. Ideal for technicians and engineers, it offers a systematic approach to understanding and managing various engine systems.

Key Features

- General Overview: Basic guidelines and introductory information (Pages 1-2).

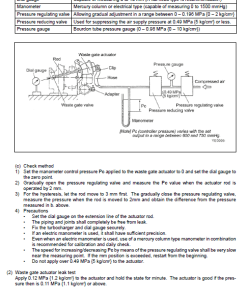

- Inspection and Adjustment: Step-by-step instructions for routine checks and adjustments (Page 2-1).

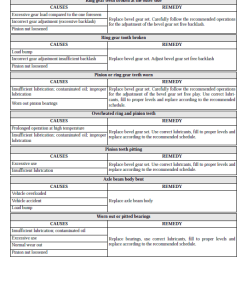

- Troubleshooting: Techniques for identifying and resolving common issues (Page 3-1).

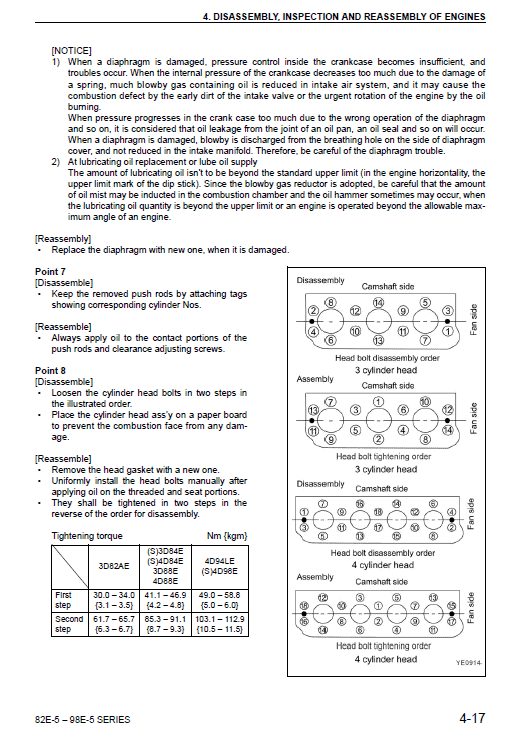

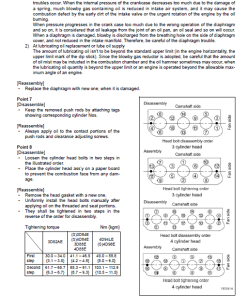

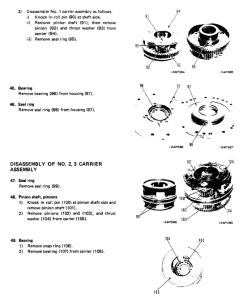

- Engine Disassembly and Reassembly: Detailed procedures for disassembling, inspecting, and reassembling engines (Page 4-1).

- Lubrication System: Insights into proper lubrication practices (Page 5-1).

- Cooling System Maintenance: Guidelines for maintaining optimal engine temperature (Page 6-1).

- Fuel Injection Pump/Governor: Information on operation and maintenance (Page 7-1).

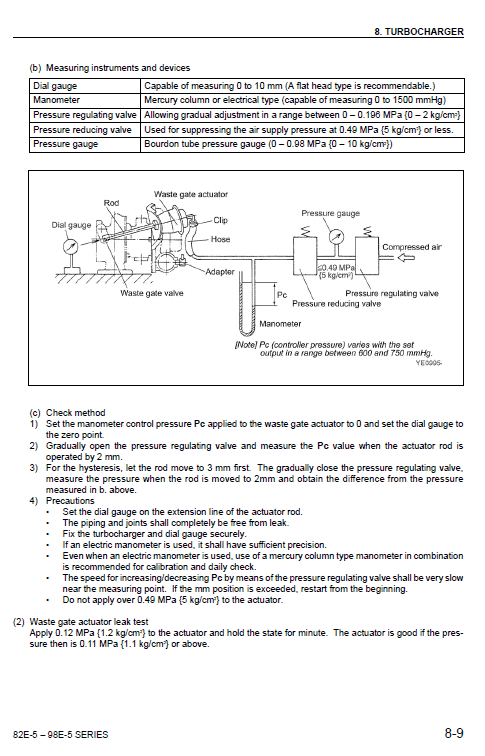

- Turbocharger Maintenance: Best practices for maintaining and repairing turbochargers (Page 8-1).

- Starting Motor: Procedures for maintaining and troubleshooting starting motors (Page 9-1).

- Alternator Maintenance: Information on maintaining electrical systems (Page 10-1).

- Electric Wiring: Details on ensuring safe and effective wiring (Page 11-1).

- Service Standards: Reference for industry-standard procedures and metrics (Page 12-1).

- Tightening Torque: Specifications for bolt and nut torque standards (Page 13-1).

Benefits

- Comprehensive Coverage: Covers all critical components and systems within engine maintenance.

- Professional Guidance: Compiled by industry experts to ensure accuracy and relevance.

- Enhanced Performance: Ensures engines operate efficiently with preventive maintenance tips.

Usage Recommendations

- Regular Reference: Use this manual as a regular reference for scheduled maintenance tasks.

- Training Tool: Ideal for training new personnel on engine systems and maintenance procedures.

- Diagnostic Aid: Utilize troubleshooting sections for diagnosing engine issues efficiently.

Additional Information

To ensure optimal performance, compare the injection angle recorded on a reassembled fuel injection pump with that of the disassembled pump. The angular difference should be zero upon reinstallation.

Formula: Fuel injection angle difference (cam angle) = (the fuel injection angle of a reassembled pump) – (the fuel injection angle of a disassembled pump).

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.