Komatsu CK35-1 Skid-Steer Loader Service Manual

$32.00

Included Manuals:

- Shop Manual: Two volumes, 304 pages each

Product Specifications:

SKU: 896191

Categories: Komatsu, Skid-Steer

CK35-1 Shop Manual

Product Overview

This CK35-1 shop manual is designed to enhance the quality of your repair work by providing a clear understanding of the product and guiding you through the correct repair procedures and judgments. Ensure you fully understand and utilize the contents of this manual to maximize its utility.

The manual primarily contains critical technical information necessary for operations in a service workshop. Each main section is organized into chapters that detail specific component groups.

Table of Contents

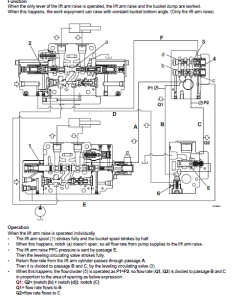

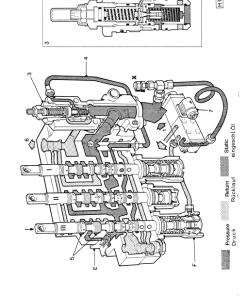

- Structure and Function

- Testing and Adjustments

- Removal and Installation

- Maintenance Standard

- Other

Key Features

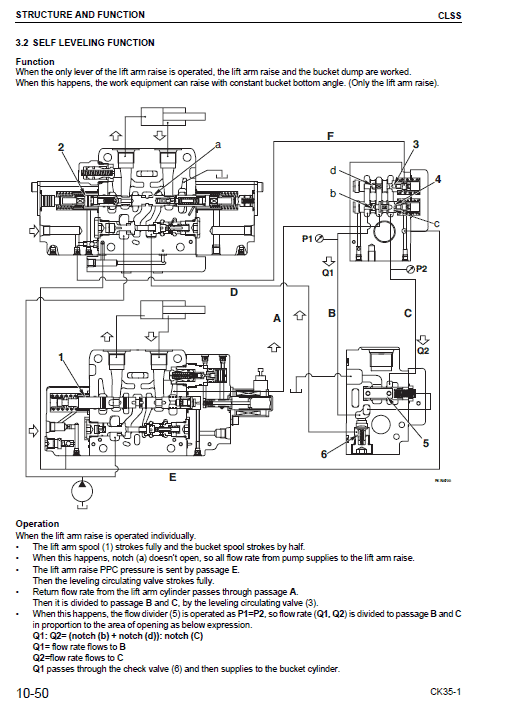

- Structure and Function: Understand the structure and function of each component, serving also as reference material for troubleshooting.

- Testing and Adjustments: Includes checks to perform before and after repairs, necessary adjustments, and troubleshooting charts connecting problems to causes.

- Removal and Installation: Provides a sequence for removing, installing, disassembling, or assembling each component, along with relevant precautions.

- Standard Maintenance: Offers standards for judging disassembled parts.

Benefits

- Enhances repair quality through precise guidance and information.

- Facilitates an accurate understanding of product components and their functionalities.

- Supports troubleshooting with structured problem identification and resolution techniques.

- Ensures safe and efficient component handling during repair operations.

Usage Recommendations

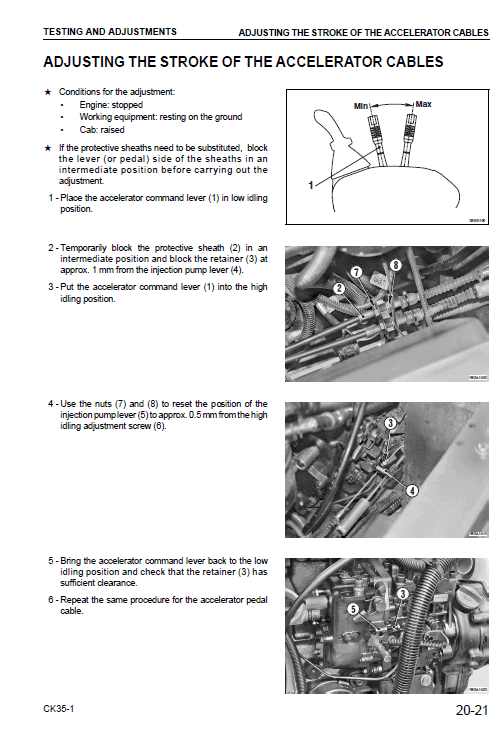

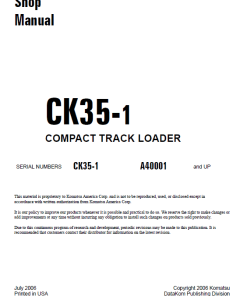

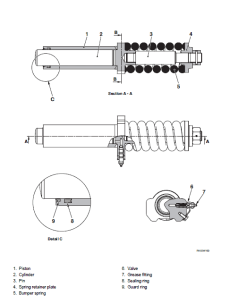

- Engine Checks:

- Verify low and high idling speeds without load (1100-1500 rpm and 2700-3500 rpm respectively).

- If speeds fall outside acceptable ranges, inspect the accelerator pedal position locks and cable sheathing before any loaded testing (refer to “Adjusting the Stroke of the Accelerator Cables”).

- For pattern change versions, ensure the pattern change valve is in ISO mode when checking engine rpm with pumps under load.

- Check maximum speeds with parking brake engaged in 2nd speed and with full lever stroke. Speeds should be 2500-2700 rpm and 2150-2450 rpm under specific conditions.

- If engine efficiency is outside permissible limits, consult an authorized workshop.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.50

Reviews

There are no reviews yet.