Komatsu D155AX-6 Dozer Service Manual

$35.00

Enhance your machinery knowledge with comprehensive manuals for the Komatsu D155AX-6 Bulldozer. This package includes:

Comprehensive Manual for Machine Maintenance and Repair

Product Overview

Our extensive manual provides detailed guidance for the maintenance and repair of various machine components. It includes comprehensive chapters focused on specifications, diagnostics, troubleshooting, and assembly procedures, ensuring an efficient workflow for technicians.

Table of Contents

- 00. Index and Foreword

- 01. Specifications

- 10. Structure, Function, and Maintenance Standard

- 20. Standard Value Table

- 30. Testing and Adjusting

- 40. Troubleshooting

- 50. Disassembly and Assembly

- 80. Appendix

- 90. Diagrams and Drawings / Repair and Replacement of Parts

Section Details

00. Index and Foreword

This section introduces the shop manual list, complete table of contents, safety protocols, and foundational information, setting the stage for effective use of the manual.

01. Specifications

Detailed specifications for each machine component are outlined to provide clear understanding and adherence to manufacturer standards.

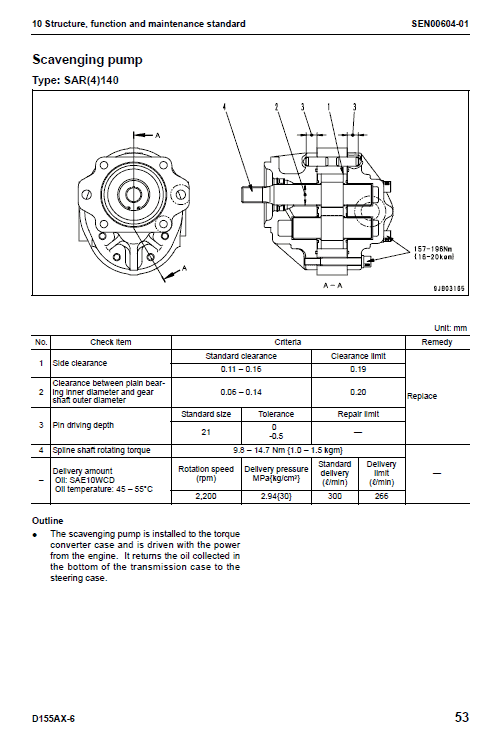

10. Structure, Function, and Maintenance Standard

This section elaborates on the construction, functionality, and maintenance benchmarks of machine components. It serves both as a structural overview and a reference for troubleshooting.

20. Standard Value Table

Establishes the benchmarks and criteria necessary for testing, adjusting, and troubleshooting, ensuring consistency across maintenance activities.

30. Testing and Adjusting

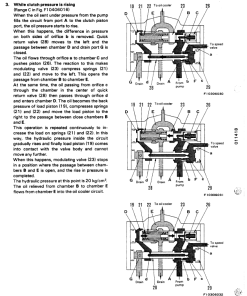

Provides methodologies for measurement and adjustment activities. It explains how to use measuring instruments effectively and outlines the procedures to achieve optimal machine performance.

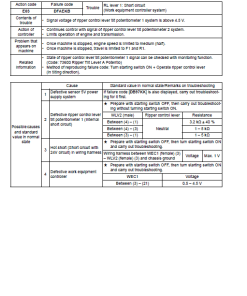

40. Troubleshooting

Offers systematic approaches to identifying and resolving component failures, categorized by potential failure modes, including references to related volumes if necessary.

50. Disassembly and Assembly

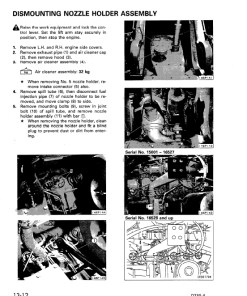

Describes the recommended tools and procedures for safely dismantling and assembling components, including specifics on torque, required materials, and precautions.

80. Appendix

Covers additional equipment and devices not included in other sections, detailing their structure, function, and troubleshooting procedures.

90. Diagrams and Drawings

Chassis Volume: Features hydraulic and electrical circuit diagrams for comprehensive system understanding.

Engine Volume: Offers guidelines for part reproduction, repair, and replacement.

Limits and Guidelines

Clearance Limit

- Defines the threshold for allowable clearance between machine parts.

- Parts must be replaced or repaired once this limit is surpassed.

Interference Limit

- Outlines allowable maximum interference levels between assembled parts.

- Parts must be replaced or repaired if interference surpasses the defined limit.

Usage Recommendations

- Regularly refer to the manual for maintenance schedules and guidelines.

- Utilize the specified tools and materials for all repairs and adjustments.

- Adhere to safety protocols as outlined in the foreword to ensure a safe working environment.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.