Comprehensive Guide for Hydraulic System Maintenance

Product Overview

This detailed manual serves as an essential resource for the effective maintenance and operation of hydraulic systems. It provides step-by-step instructions, troubleshooting tips, and specifications necessary for the upkeep of high-performance machinery. Whether you’re involved in assembly, disassembly, or routine checks, this guide offers the knowledge you need for efficient system management.

Table of Contents

- Index and Foreword

- Specification

- Structure and Functions

- Standard Value Table

- Testing and Adjusting

- Troubleshooting

- Disassembly and Assembly

- Appendix

- Circuit Diagrams

- Index

Key Features

- Detailed instructions for bleeding air and flushing cylinders

- Comprehensive circuit diagrams for troubleshooting

- Clear guidance on oil level and maintenance checks

Benefits

- Efficient Maintenance: Streamlined processes ensure your equipment remains in peak condition.

- Ease of Use: Clearly illustrated diagrams and step-by-step instructions enhance understanding.

- Cost-effectiveness: Minimize downtime by following preventative measures outlined in the manual.

Usage Recommendations

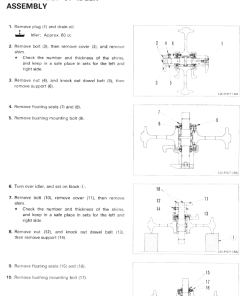

- Bleeding Air and Flushing Cylinder with Piston Valve:

- Run the engine at low idle. Extend and retract the cylinder for five minutes without reaching the end of the stroke.

- Operate the piston rod approximately 100 mm from the end of the stroke. Avoid relieving the circuit.

- Retract the cylinder to 100 mm before the end. Use fine control to retract to the stroke’s end, holding for 3 minutes.

- Bleeding Air and Flushing Cylinder without Piston Valve:

- Check the hydraulic tank oil level. Ensure it’s between ‘L’ and ‘H’ on the sight gauge. Refer to procedure u201cA-10-4u201d for proper checking.

- Run the engine at low idle. Extend and retract the cylinder for five minutes without reaching the stroke’s end.

- Operate the piston rod approximately 100 mm from the end of the stroke, avoiding circuit relief.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$33.50

Reviews

There are no reviews yet.