Shop Manual for Equipment Maintenance and Troubleshooting

Product Overview

This comprehensive shop manual is an essential resource for performing technical services in a workshop setting. It is meticulously organized into well-defined sections, each providing crucial information and guidelines for maintenance, testing, troubleshooting, and assembly of machinery components.

Key Features

- Index and Foreword: Introduction to the manual with general information for efficient use.

- Specifications: Detailed specifications and technical data of the machine.

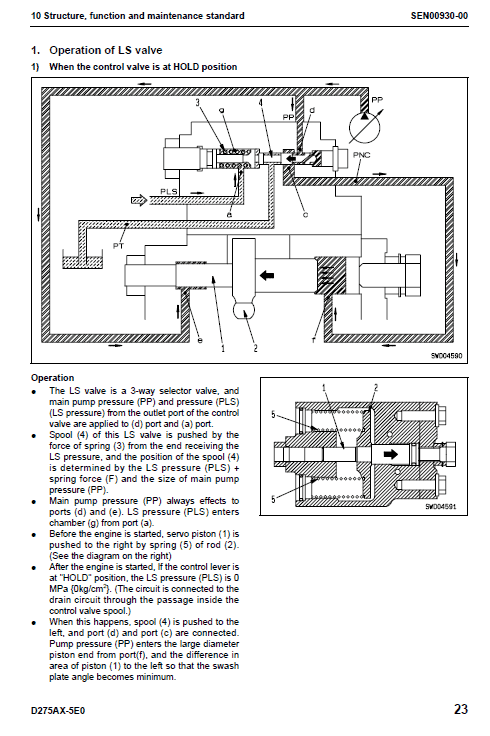

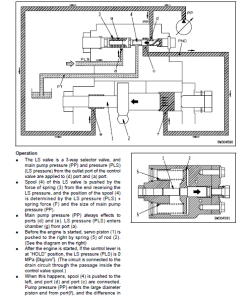

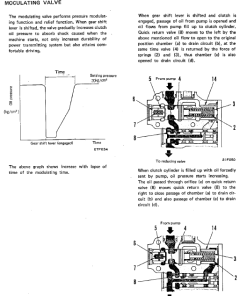

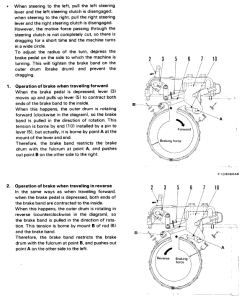

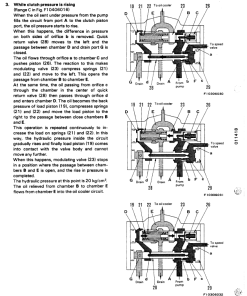

- Structure and Function: Descriptions of the engine and cooling systems, power train, undercarriage, hydraulic systems, cab structures, and electrical systems.

- Standard Value Tables: Reference tables with standard service values for new machines, essential for troubleshooting and adjustments.

- Testing and Adjusting: Guidelines on testing methods and tools, covering standard values and adjustment protocols.

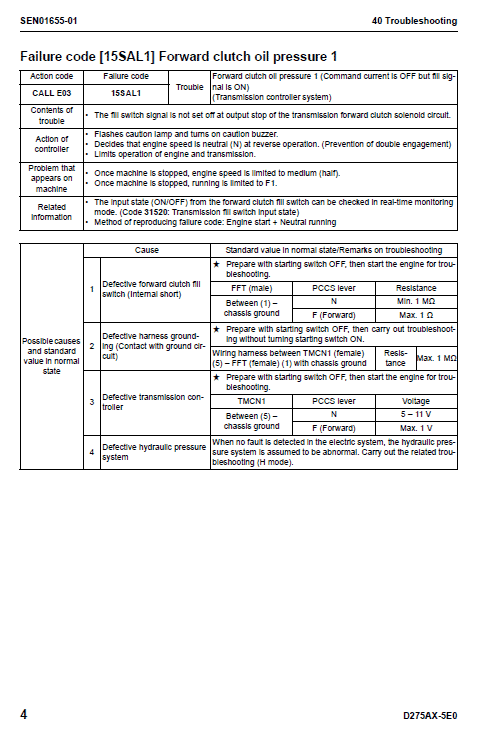

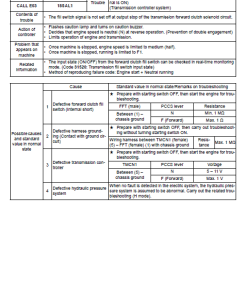

- Troubleshooting: Process for identifying failure modes and repair strategies, including reference to specific parts such as the engine and chassis.

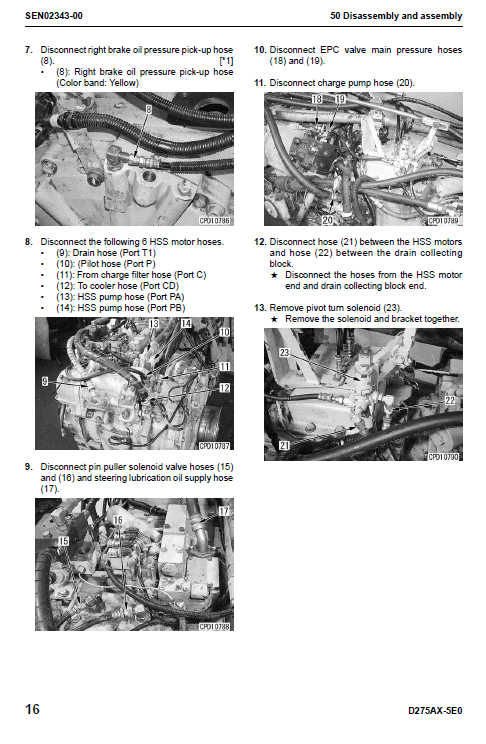

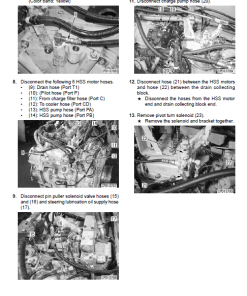

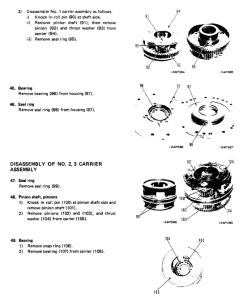

- Disassembly and Assembly: Step-by-step instructions with details on special tools and precautions.

- Maintenance Standards: Criteria and remedies for component disassembly and service.

- Appendix and Additional Information: Covers equipment that is not included in the main sections.

- Diagrams and Drawings: Hydraulic and electrical circuit diagrams to aid understanding.

Benefits

- Comprehensive Resource: Provides complete technical information for all aspects of machine maintenance and repair.

- Organized Structure: The manual is divided into sections for easy navigation and quick reference.

- Enhanced Troubleshooting: Detailed failure codes and resolution strategies to minimize downtime.

Usage Recommendations

- Perfect for Workshops: An essential guide for technicians and engineers working in a professional workshop environment.

- Reference for Troubleshooting: Use failure code sections for rapid identification and solution of machine issues.

- Guide for Maintenance: Follow the maintenance standard values to ensure equipment operates at optimal efficiency.

For further clarification or to address specific failure codes like those noted such as the Power Train Oil Temp Sensor or Steering Potentiometers, consult the relevant troubleshooting sections in the manual.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.50

$34.00

$33.00

Reviews

There are no reviews yet.