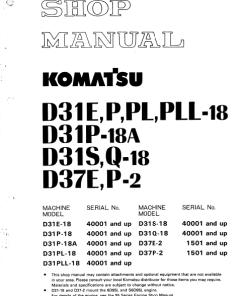

Comprehensive Shop Manual

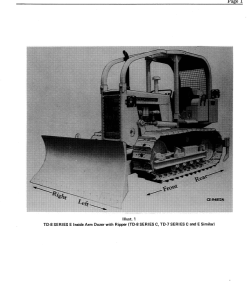

Product Overview

This detailed shop manual is an essential resource for technicians and engineers, providing comprehensive information and guidance for servicing a variety of machine components. Designed for ease of use, the manual is organized into major sections, each indexed by title and accessible through individual section tabs. Whether you need specifications or recommendations for special tools, lubricants, or adjustments, this manual has it all.

Key Features

- Extensive coverage of machine specifications and tolerances.

- Guidelines for using service and special tools.

- Detailed assembly tips and service bulletins.

- Indexed major sections for easy navigation.

Benefits

- Enhances your ability to perform accurate repairs and maintenance.

- Reduces downtime with clear and concise instructions.

- Improves longevity of equipment through proper servicing.

- Supports informed decision-making with comprehensive technical data.

Usage Recommendations

- Locate the necessary section in the manual using the index tabs for quick reference.

- Replace pins and bushings as needed, ensuring the links justify new components.

- Measure track pitch length under tension to monitor wear and maintain optimal function.

- Consider sprocket wear alongside track chain maintenance to prevent phase misalignment.

- Install new or rebuilt track chains with corresponding sprocket updates for balanced wear.

Section Highlights

- Miscellaneous – Section 2

- Cooling – Section 6

- Drive Train – Section 7

- Torque Converter – Section 7B

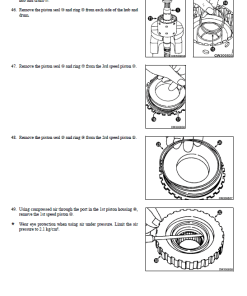

- Transmission – Section 7C

- Steering Drive – Section 7E

- Sprocket Drive – Section 7F

- Electrical – Section 8

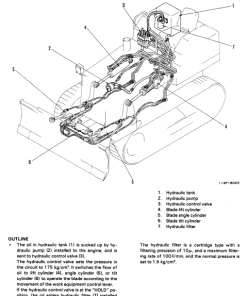

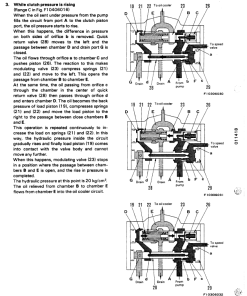

- Hydraulics – Section 10

- Pumps and Motors – Section 10A

- Control Valve – Section 10B

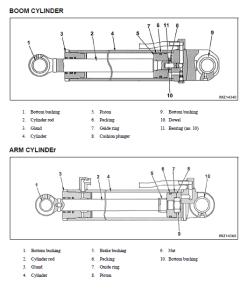

- Cylinders – Section 10C

- Power – Section 12

- Undercarriage – Section 14

- Track Chain – Section 15

- Mounted Equipment – Section 17

Maintenance Tips

Track links should be inspected regularly as they have only one wearing surface that makes contact with track rollers, front idlers, and track idlers. Visible wear on the outside of bushings and track stretch can indicate the need for replacement. Measure the pitch length of the track and compare it to new standards to check for wear. Regularly evaluate both sprocket and track chain wear to avoid misalignment and reduce excessive wear on sprocket teeth.

When installing new or rebuilt track chains, it is advisable to also update sprockets. Removing a link from a stretched track to fit adjustments should be avoided, as it may lead to misalignment and increased sprocket wear.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.