Maintenance Manual Overview

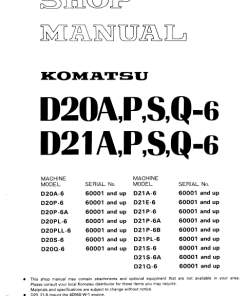

Product Overview

This Maintenance Manual is an essential resource designed to provide comprehensive guidelines and procedures for service technicians. It covers aspects from basic principles to detailed troubleshooting, ensuring effective repair and maintenance support.

Table of Contents

- 00 Index and Foreword

- 01 Specification

- 10 Structure, Function, and Maintenance Standard

- 20 Standard Value Table

- 30 Testing and Adjusting

- 40 Troubleshooting

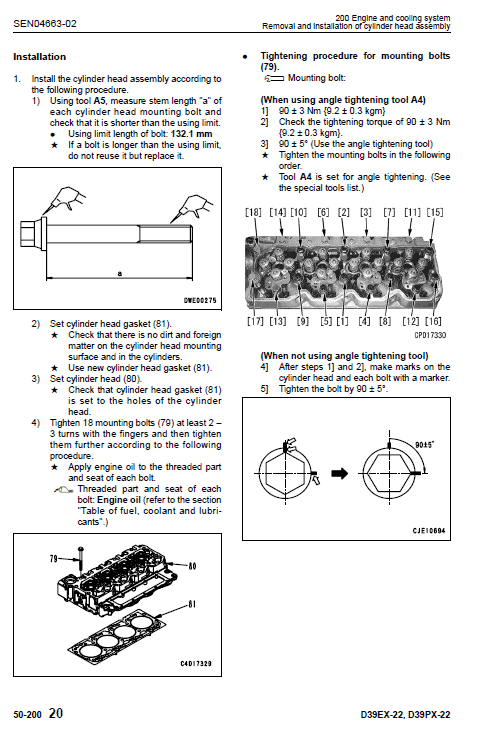

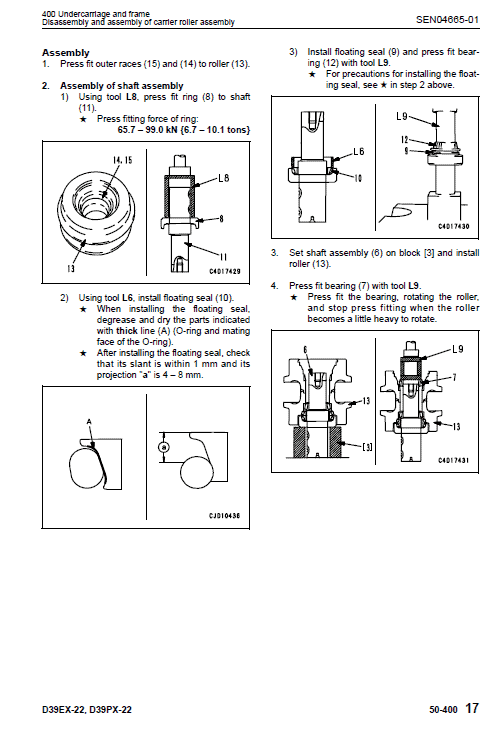

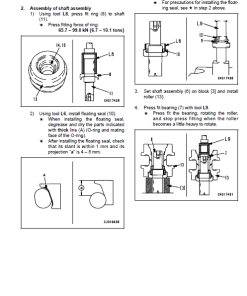

- 50 Disassembly and Assembly

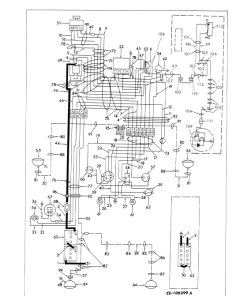

- 90 Diagrams and Drawings

General Instructions

This section consolidates the fundamental information and procedures applicable across various sections such as “Disassembly and Assembly”, “Testing and Adjustments”, “Troubleshooting”, and “Removal and Installation”. It is crucial for technicians to become thoroughly familiar with this content, integrating it into their working knowledge.

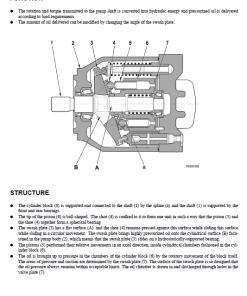

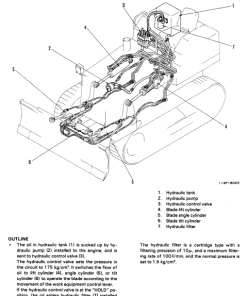

Structure and Function

Here, detailed explanations of the equipment’s structure are provided, including constituent parts and relevant diagrams. This section serves both as a guide for technicians and a training textbook, making use of training aids to underpin the manual’s foundational theories.

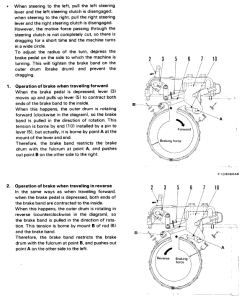

Testing and Adjustments

This section details the necessary tests and adjustments, accompanied by photographs showing required measuring equipment and locations for taking measurements. It supports technicians in troubleshooting, checking, and adjustment activities.

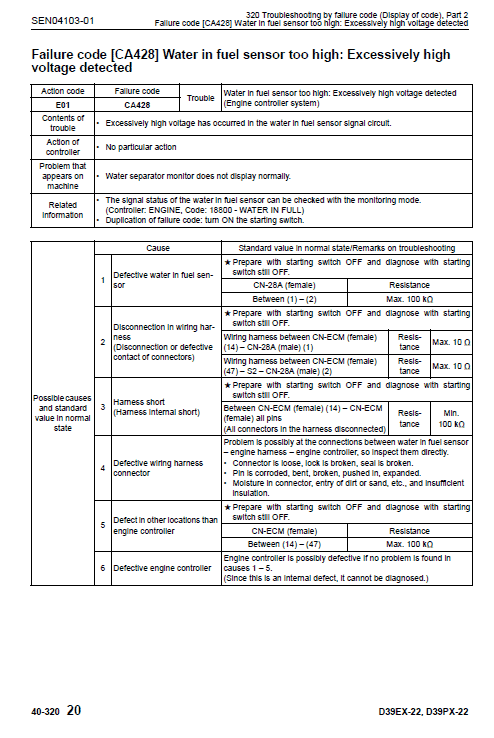

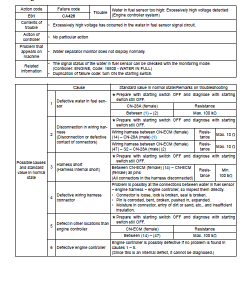

Troubleshooting

Common issues are systematically listed, complete with causes and diagnostic procedures. While it is impossible to cover every potential problem, technicians are advised to study “Structure and Function” and “Testing and Adjustments” sections to apply this knowledge to diagnose unlisted issues effectively.

Manual Specifications

This section outlines all standard dimensions and tolerances necessary for testing, adjustments, and repairs, including detailed drawings and procedures. Focus is placed on the machine parts most frequently serviced.

Troubleshooting Example: Coolant Temperature Gauge Inaccuracy

- The gauge remains in the white range despite normal coolant temperature rise.

- The gauge rises to the red range even when the coolant temperature is stable.

Possible Causes:

- Defective coolant temperature sensor circuit

- Faulty monitor panel

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.