Komatsu D575A-3 Dozer Service Manual

Product Overview

This comprehensive service manual for the Komatsu D575A-3 Dozer is essential for professionals tasked with maintaining and repairing this powerful machine. The manual provides detailed sections covering everything from machine dimensions to troubleshooting solutions, ensuring that you have all the necessary information to keep the dozer functioning optimally.

Key Features

- General Information: Includes machine dimensions, performance specifications, component weights, and vital charts for fuel, coolant, and lubricants.

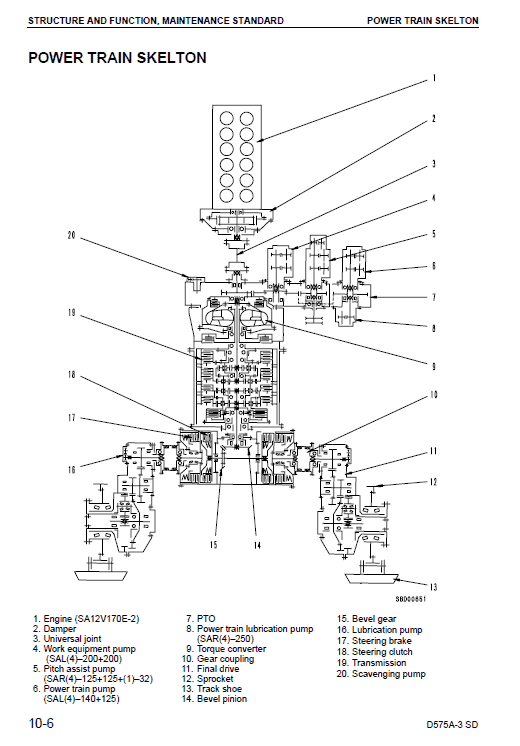

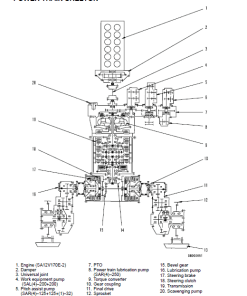

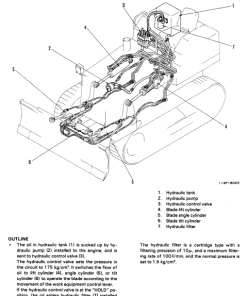

- Structure, Function, and Maintenance: Offers insights into the machine’s components, assisting with both understanding and troubleshooting. This section also includes judgment standards for inspecting disassembled parts.

- Testing and Adjusting: Details the checks required before and after repairs, and the adjustments needed to maintain high performance.

- Troubleshooting: Features charts that correlate common problems with their causes for efficient diagnostics.

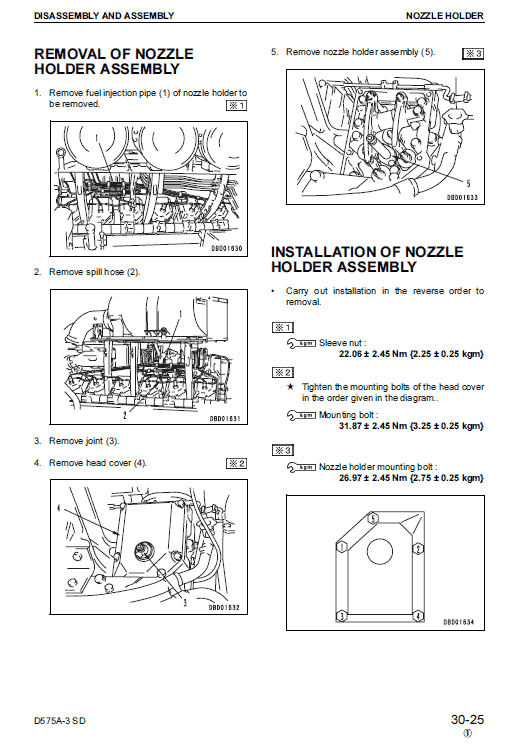

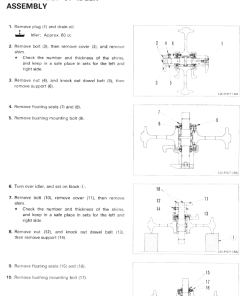

- Disassembly and Assembly: Guides the sequential order for component removal, installation, disassembly, and assembly, with precautions for safe operations.

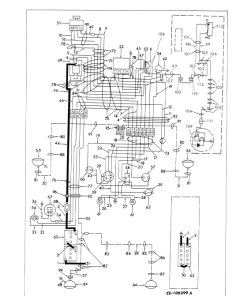

- Other Information: Foldout drawings for comprehensive machine visualization.

Benefits

- Ensures thorough understanding of the Komatsu D575A-3 Dozer.

- Aids in accurate diagnostics and efficient repairs.

- Enhances maintenance procedures with detailed guidelines.

Usage Recommendations

- Utilize this manual as a reference for regular maintenance checks to prevent machine downtime.

- Follow the disassembly and assembly instructions precisely to ensure safety and integrity of the machine components.

- Use the troubleshooting section to quickly identify and resolve issues, minimizing the impact on operations.

Adjusting Track Shoe Tension

If the track shoe tension deviates from the normal range, follow these steps:

- Remove the cover.

- If the tension is too high: Loosen the plug (1) gradually and release some grease. Be cautious of high internal pressure to avoid potential hazards; never loosen the plug more than one turn.

- If the tension is too low: Inject grease through the grease fitting (2). For best results, move the machine slowly backward or forward to stabilize the track tension.

- After adjustment, repeat the procedure to verify the tension is appropriate.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.50

Reviews

There are no reviews yet.