Komatsu Track Shoe Assembly Manual

Product Overview

This comprehensive manual provides detailed service and repair guidelines for the optimal and safe operation of Komatsu machinery. Developed by Komatsu experts, the manual includes proven techniques and methods specifically designed for machine maintenance, ensuring safety and efficiency. Some procedures necessitate Komatsu-specific tools, meticulously crafted for these specific repairs.

Key Features

- Detailed Index and Foreword: A structured introduction for easy navigation.

- Exact Specifications: Full specifications to guide proper maintenance.

- Comprehensive Structure, Function, and Maintenance Standards: Extensive information on machine operation and upkeep.

- Standard Value Tables: Reference tables for maintenance precision.

- Testing and Adjusting Procedures: Complete guidelines ensuring equipment accuracy.

- Thorough Troubleshooting: Solutions and resolutions for common issues.

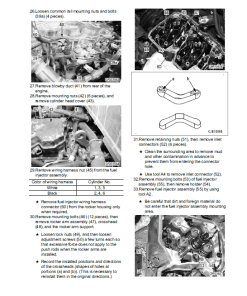

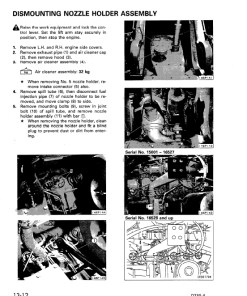

- Disassembly and Assembly Instructions: Step-by-step guidance for machine parts.

- Maintenance Standards: Best practices for sustained machine performance.

- Comprehensive Appendix: Additional information and clarification.

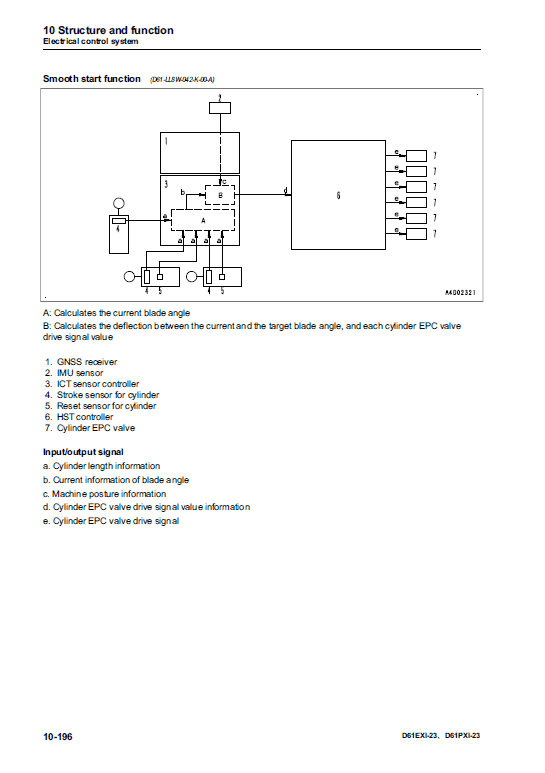

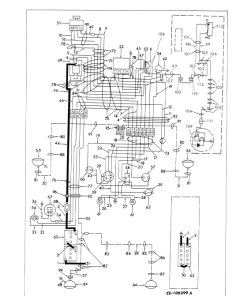

- Diagrams and Drawings: Visual aids for better understanding and clarity.

Benefits

- Enhanced Safety: Adherence to recommended practices reduces risks during maintenance.

- Increased Longevity: Proper maintenance extends the lifespan of machinery.

- Efficiency Boost: Well-maintained equipment functions optimally.

- Cost-Effectiveness: Preventive maintenance minimizes costly repairs.

Usage Recommendations

- Track Shoe Assembly: Position the assembly on a flat surface with shoes facing up. Remove track shoe bolts manually from the master link and proceed with shoe removal, avoiding impact wrenches.

- Handling and Disassembly: For large assemblies, divide into smaller quarter assemblies for easier management.

- Repositioning: Lift the track shoe carefully to avoid damaging master links. If gas cutting is necessary, maintain temperatures below 80u00b0C to preserve seal integrity.

- Oil Draining: Drain oil before disassembling the link assembly to avoid smearing. If converting to a dry track type, skip this process.

- Removing Burrs: Use a grinder to chamfer pin ends and remove burrs, preventing damage during disassembly and avoiding oil leaks post-reassembly.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$32.50

Reviews

There are no reviews yet.