Service Manual Overview

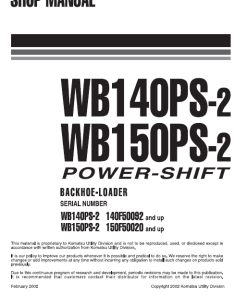

Product Overview

This Service Manual is designed to provide comprehensive guidelines for maintenance, troubleshooting, and operation of equipment. It includes detailed sections that are essential for understanding and performing service tasks effectively. The manual is suitable for service personnel, offering clear, structured instructions for various maintenance procedures.

Table of Contents

- 00 Index and Foreword

- 01 Specification

- 10 Structure, Function, and Maintenance Standard

- 20 Standard Value Table

- 30 Testing and Adjustments

- 40 Troubleshooting

- 50 Disassembly and Assembly

- 90 Diagrams and Drawings

Sections Overview

1. General Instructions

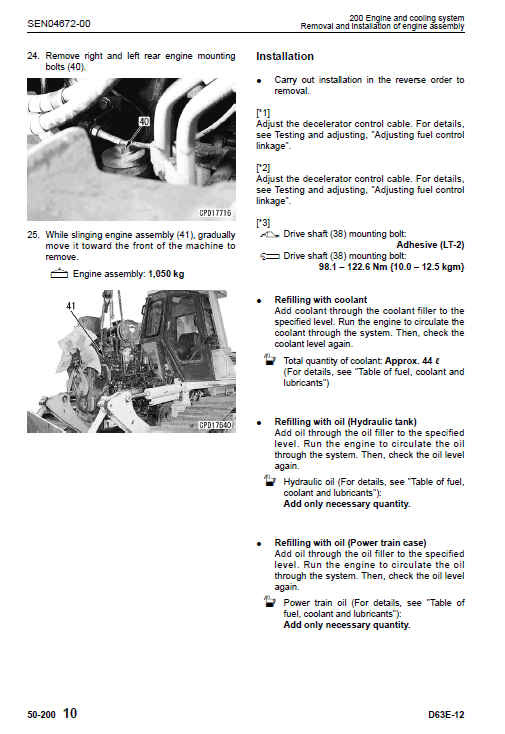

This section consolidates fundamental information and procedures that apply to “Disassembly and Assembly”, “Testing and Adjustments”, “Troubleshooting”, and “Removal and Installation”. It is critical for service technicians to master this section until these instructions become second nature.

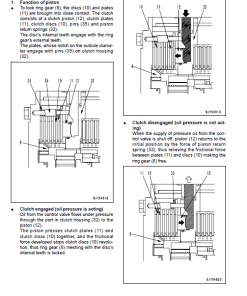

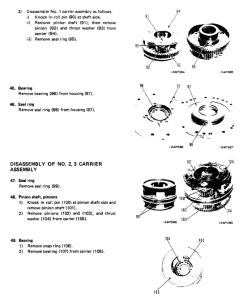

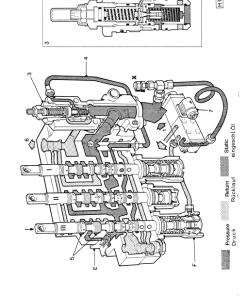

2. Structure and Function

This part offers an in-depth explanation of the equipment’s “Structure”, complete with detailed descriptions and illustrative diagrams. It is organized for service technicians but also serves as an educational resource for training purposes. Utilize training aids to enhance understanding of the theoretical aspects covered in this manual.

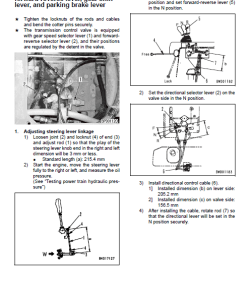

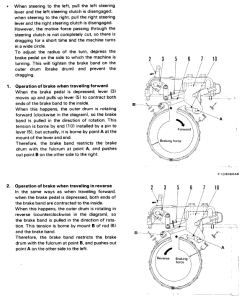

3. Testing and Adjustments

Here, all necessary tests and adjustment procedures are detailed with photographs. These visuals show the required measuring equipment and correct measurement locations, aiding technicians in effective troubleshooting, verification, and calibration work.

4. Troubleshooting

This section provides a systematic listing of typical issues, their causes, and diagnostic procedures. As not all potential problems can be cataloged, users should refer to the “Structure and Function” and “Testing and Adjustments” sections to apply their knowledge to diagnose any unlisted issues.

5. Manual Specifications

This section outlines all standard dimensions and tolerances critical for conducting tests and adjustments. It includes relevant diagrams and procedures for disassembly, assembly, repair, or troubleshooting, focusing on the most commonly serviced machine parts.

Usage Recommendations

- Handling of Wiring Harnesses: Clean any oil or dirt using a dry cloth. Avoid washing with water or steam. If necessary, do not use high-pressure water or steam directly on the wiring harness. In case water reaches the connector, disconnect it and dry it with a cloth.

- Avoid using compressed air with oil contaminants to dry the connectors, as this may lead to poor contact. Ensure all oil and water are removed from air before using compressed air for drying.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.