Shop Manual Overview

Product Overview

This comprehensive shop manual provides the technical information necessary for performing essential services in a professional workshop setting. To ensure a thorough understanding, the manual is meticulously divided into distinct sections, each addressing specific areas of machinery maintenance and operation.

Key Sections

- 00. Index and Foreword: Offers general information and a preface to the manual’s content.

- 01. Specification: Details the machine’s specifications and technical data.

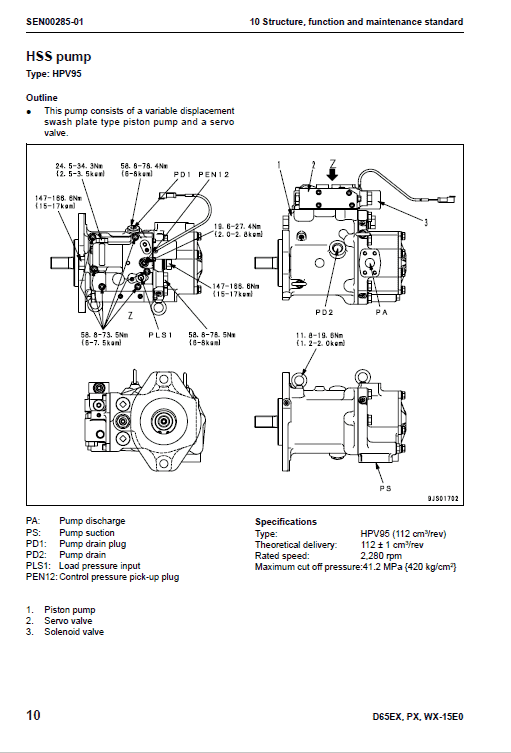

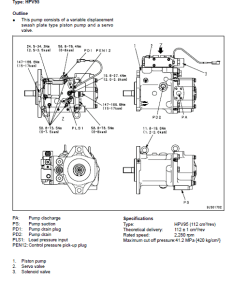

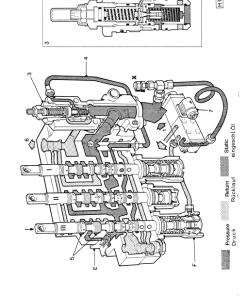

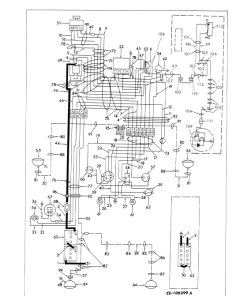

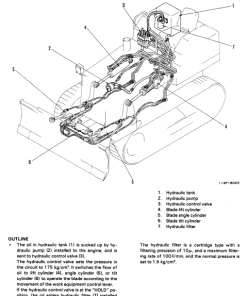

- 10. Structure and Function: Describes the structure and function of each component, enabling effective troubleshooting.

- 20. Standard Value Table: Provides standard values for new machines and criteria for testing and adjustment purposes.

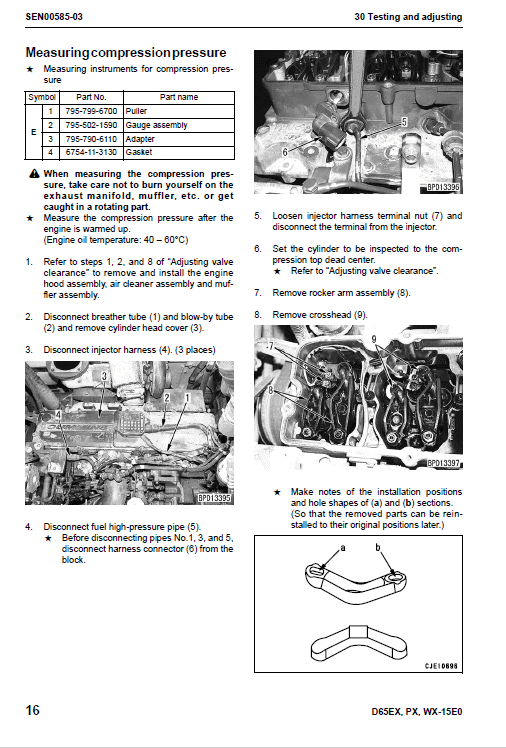

- 30. Testing and Adjusting: Explains measuring tools and methods for accurate testing and adjustments.

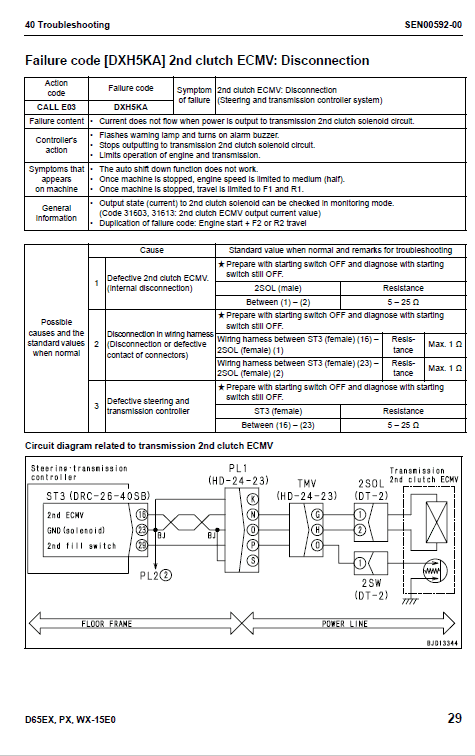

- 40. Troubleshooting: Guides users through identifying failed parts and executing appropriate repairs.

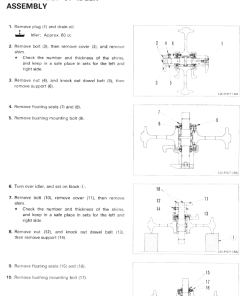

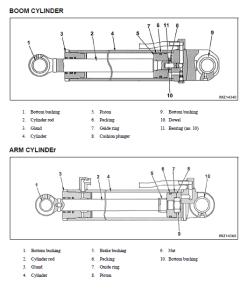

- 50. Disassembly and Assembly: Includes procedures and tools for efficient component disassembly and reassembly, with safety precautions.

- 60. Maintenance Standard: Sets forth maintenance standards, including remedies and criteria for service and disassembly.

- 80. Appendix: Covers additional equipment, explaining structure, function, and troubleshooting

- 90. Diagrams and Drawings: Provides detailed hydraulic and electrical circuit diagrams.

Benefits

- Comprehensive Information: Covers all necessary technical aspects for effective maintenance and repairs.

- Sectioned Layout: Allows for quick access and easy navigation through relevant materials.

- Enhanced Troubleshooting: Detailed failure mode analysis aids in precise diagnosis and correction.

Usage Recommendations

- Consult the Specification section before starting maintenance work to understand machine capabilities.

- Use the Testing and Adjusting section for accurate calibration.

- Refer to the Disassembly and Assembly section for guidance on component handling to ensure safety and accuracy.

- Apply the Troubleshooting procedures to diagnose and rectify issues using failure codes.

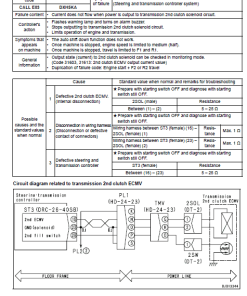

Classification and Procedures of Troubleshooting

When a failure code has been recorded but no action code is visible on the monitor, display the failure in the relevant system mode on the monitor display (EMMS). Use appropriate troubleshooting techniques corresponding to the failure code to ensure accurate repairs.

- Even if the failure code displays when the starting switch is on, ensure to verify and correct the issue as appropriate.

- If no failure code is recorded, check the symptoms again and follow the appropriate troubleshooting mode, i.e., E-Mode, H-Mode, or S-Mode, based on observed symptoms.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$33.50

Reviews

There are no reviews yet.