Komatsu GD825A-2 Motor Grader Service Manual

$34.00

Manual Details:

- Pages: 926 (Shop Manual)

Specifications:

Motor Grader Shop Manual

Product Overview

This comprehensive shop manual provides essential technical information required for servicing your Motor Grader model GD825A-2, serial 10002 and up. It is meticulously organized into sections for enhanced understanding and ease of use in a workshop setting.

Composition of the Shop Manual

The manual is systematically divided into the following sections, each designed to provide detailed insights and guidelines:

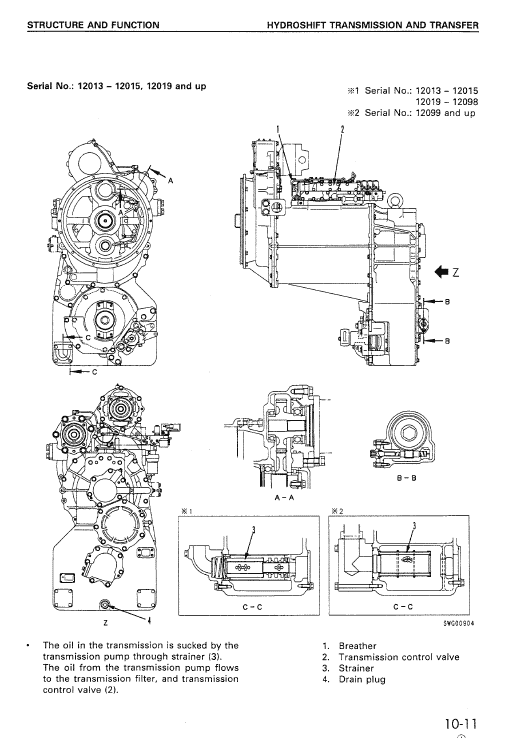

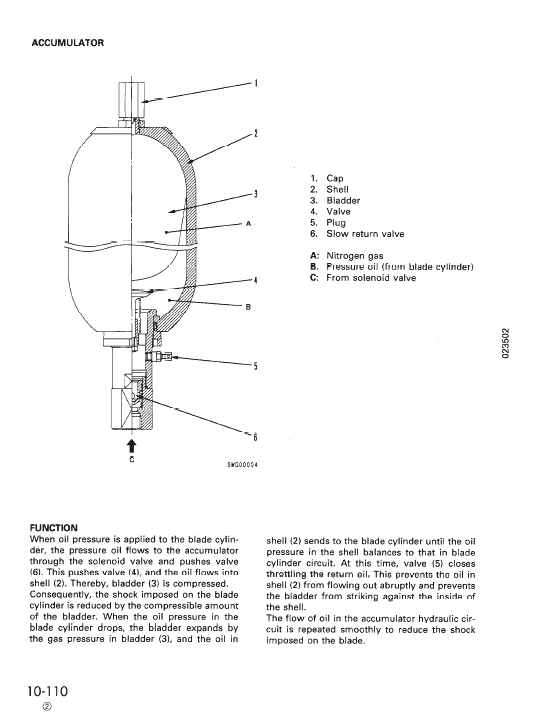

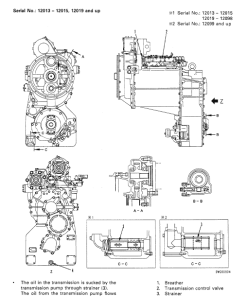

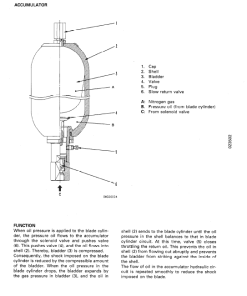

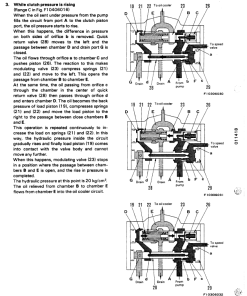

1. Structure and Function

This section delves into the detailed structure and function of each component. It not only offers a foundational understanding of each part but also acts as valuable reference material for troubleshooting issues that may arise during operation.

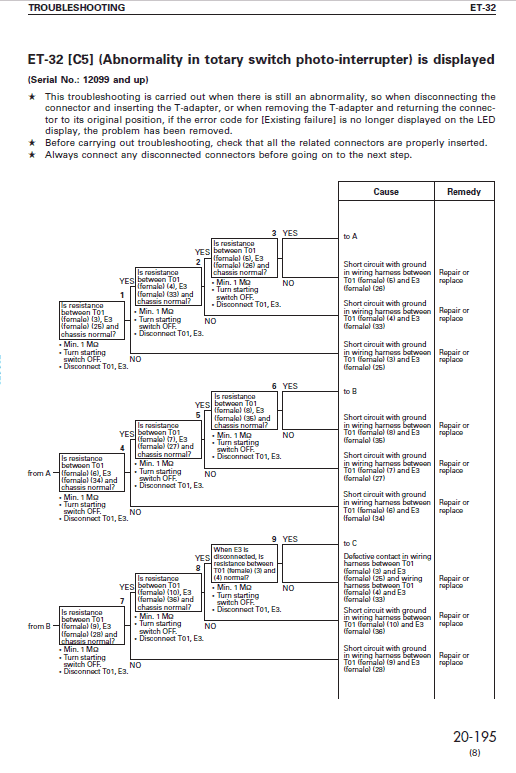

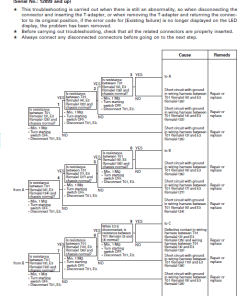

2. Testing, Adjusting, and Troubleshooting

Learn the essential checks to perform before and after repairs, along with adjustments to finalize checks and repairs. Troubleshooting charts are included, correlating specific problems with their causes to aid in effective resolution.

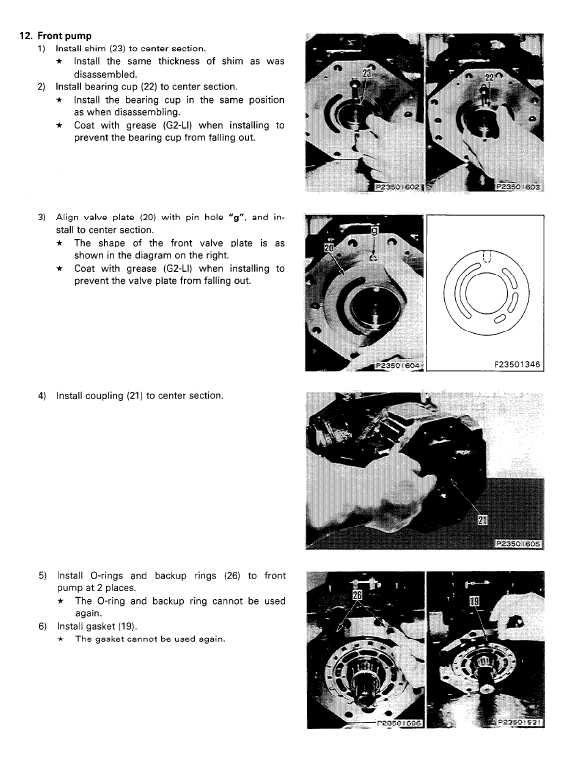

3. Disassembly and Assembly

Explore specialized tools and procedures required for component removal, installation, disassembly, and assembly. This section also covers necessary precautions, tightening torque, and detailed specifications of coating material, oil, grease, and coolants for each task.

4. Maintenance Standard

Understand the standards for assessing disassembled parts, which is crucial for discerning usability and determining maintenance needs.

Key Features

- Structure Insight: Comprehensive details of each component’s structure and function.

- Troubleshooting: Easy-to-follow troubleshooting charts for problem resolution.

- Technical Specifications: Includes necessary specifications for repairs and maintenance.

- Professional Guidance: Step-by-step procedures for disassembly and assembly.

Benefits

- Enhances understanding of motor grader components and their functionality.

- Aids in accurate troubleshooting and problem-solving.

- Ensures proper maintenance and servicing of your machine.

- Facilitates efficient and effective repairs using recommended procedures and standards.

Usage Recommendations

- Prioritize reading each relevant section before performing maintenance tasks.

- Use provided troubleshooting charts to quickly diagnose and address issues.

- Follow recommended disassembly and assembly procedures for optimal safety and performance.

- Regularly consult maintenance standards to keep machinery in top condition.

Only logged in customers who have purchased this product may leave a review.

Challenger MT295 Tractor Service Manual

Challenger MT295 Tractor Service Manual

Reviews

There are no reviews yet.