Komatsu HM350-1 Dump Truck Service Manual

$35.00

Enhance your understanding and maintenance of the Komatsu HM350-1 Dump Truck with our comprehensive manuals.

SKU: 913983

Categories: Dump Truck, Komatsu

Machine Maintenance and Repair Guide

Product Overview

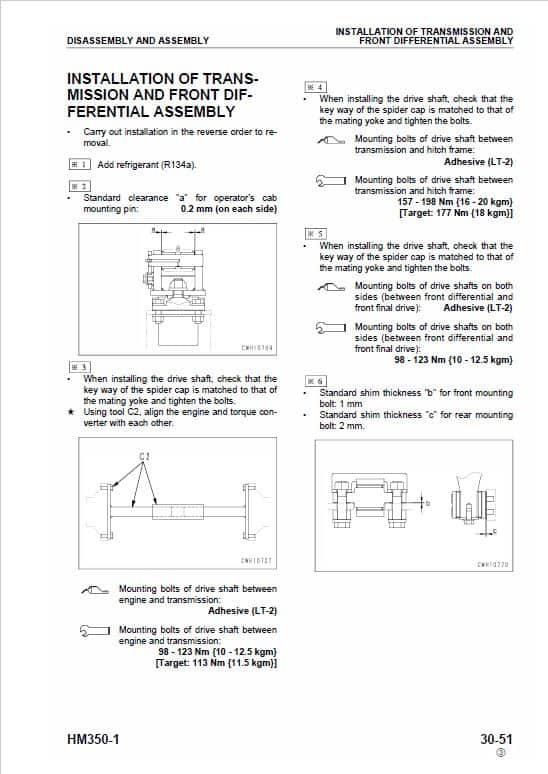

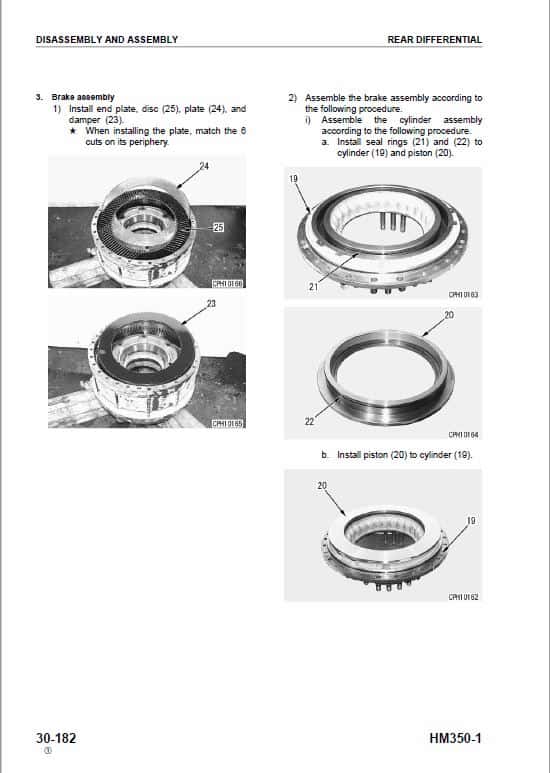

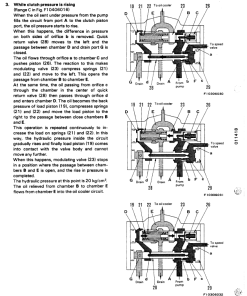

To ensure the longevity and optimal performance of machines, it is essential to follow correct operation, maintenance, inspection, troubleshooting, and repair protocols. This guide provides detailed instructions for repairing mechatronics systems, focusing on enhancing repair quality. It includes critical sections on handling electric and hydraulic equipment, with specific attention to gear oil and hydraulic oil.

Key Features

- Comprehensive Repair Procedures: Includes complete steps for effective mechatronics repair, ensuring high-quality outcomes.

- Electrical Equipment Handling: Detailed guidance on proper techniques for dealing with electric components.

- Hydraulic Equipment Focus: Specific instructions on managing hydraulic systems and fluids like gear and hydraulic oils.

Benefits

- Prevent Failures: Proactively addresses potential issues before they lead to system failures.

- Extended Machine Life: Ensures machines operate efficiently over an extended period with proper maintenance.

- Enhanced Repair Quality: Provides techniques to improve the reliability and efficiency of repair operations.

Usage Recommendations

- Wiring Harnesses and Connectors: Manage with care to avoid deformation or damage, especially when exposed to rain, water, heat, or vibration. Frequent reconnection during inspections requires careful handling.

- Protective Measures: Use protectors or tubes to safeguard wiring, ensuring they are less likely to incur damage during routine operations or unexpected events.

- Regular Maintenance Checks: Conduct frequent inspections and follow the guide’s procedures to maintain the machine’s operational health.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.00

$34.00

Reviews

There are no reviews yet.