Shop Manual for Excavator

Product Overview

The Shop Manual provides comprehensive technical information essential for servicing Excavators in a workshop setting. It is organized into multiple sections to facilitate understanding and implementation of procedures. These sections cover everything from specifications to troubleshooting and assembly instructions.

Key Features

- Foreword: An introduction covering safety protocols and essential information.

- General Specifications: Detailed specifications of the Excavator machinery.

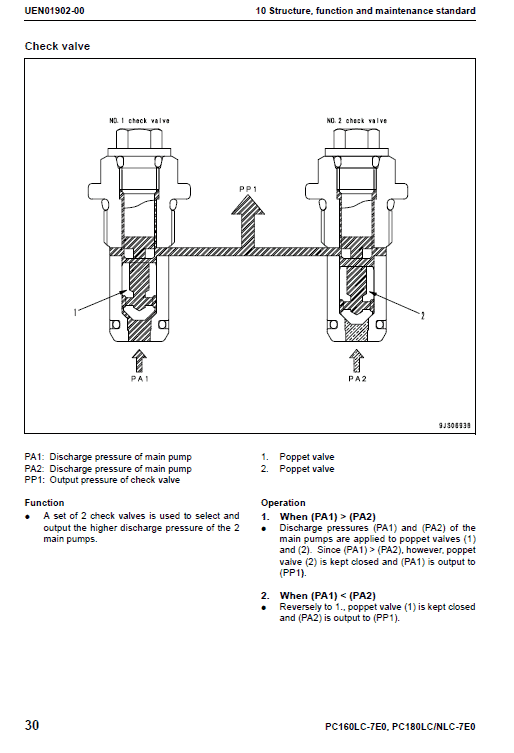

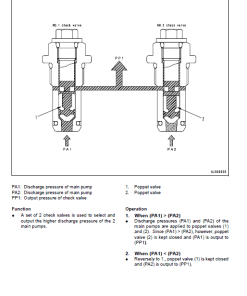

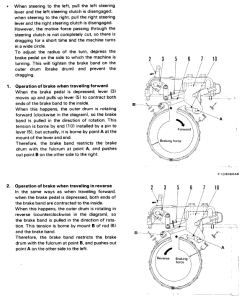

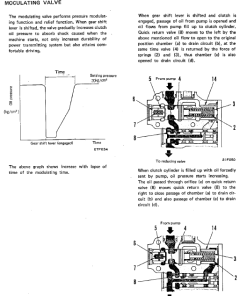

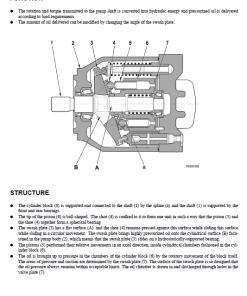

- Structure and Function, Maintenance Standards: Explains the design and functionality of each component and sets maintenance standards.

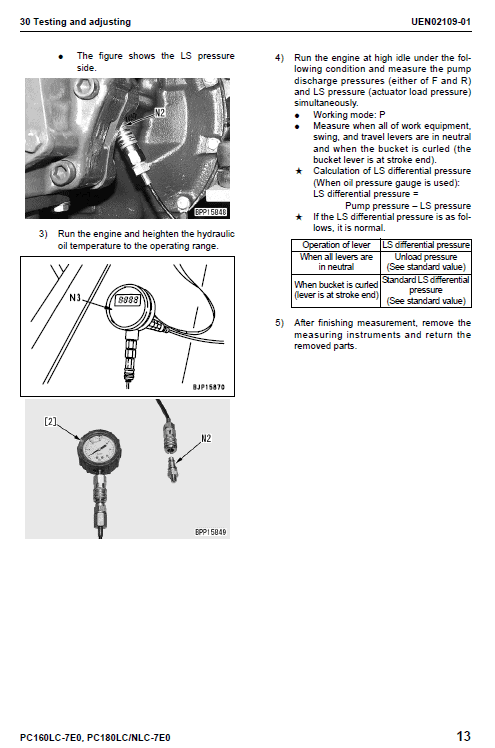

- Testing and Adjusting: Includes standard values for machine assessment and explanation on using measuring instruments and methods of adjustment.

- Troubleshooting: Methods to diagnose and rectify faults, categorized by failure modes, with specific reference to related sections for engine issues.

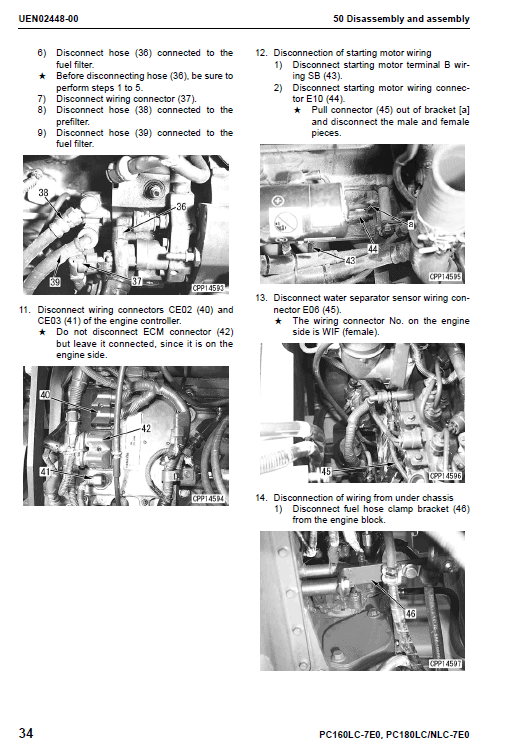

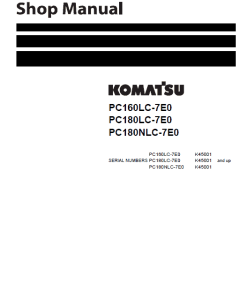

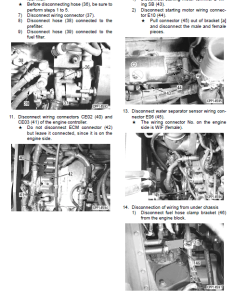

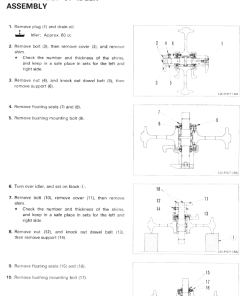

- Disassembly and Assembly: Guidance on the tools and procedures for component removal and assembly, including necessary material specifications.

- Diagrams and Drawings: Provides hydraulic and electrical circuit diagrams for comprehensive understanding.

Benefits

- Structured layout ensures easy navigation and quick reference during maintenance tasks.

- Standard value tables enhance accuracy in testing and troubleshooting decisions.

- Comprehensive instructions aid both novice and experienced technicians in equipment servicing.

- Important safety information and procedural precautions ensure safe practice.

Usage Recommendations

- Before servicing, thoroughly review the Foreword to understand safety protocols.

- Utilize the Testing and Adjusting section for evaluating machine performance accurately.

- Refer to Troubleshooting for systematic diagnosis of engine and chassis issues.

- When undertaking component work, consult Disassembly and Assembly for proper procedural guidance and material requirements.

- For safe relief of residual fuel pressure, ensure the engine has stopped for at least 30 seconds before inspection.

Releasing Residual Pressure from Fuel System

The fuel system generates pressure within both the low-pressure and high-pressure circuits while the engine operates.

- The pressure in both circuits automatically reduces to a safe level 30 seconds after engine shutdown.

- Prior to inspecting the fuel system or removing parts, ensure all residual pressure is fully released.

- Always wait at least 30 seconds post engine shut-off before commencing work on the fuel system to ensure safety.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.50

$34.00

Reviews

There are no reviews yet.