Shop Manual for Excavator: Comprehensive Guide

Product Overview

This shop manual is an essential resource, providing all the technical information necessary for service operations conducted within a workshop environment. To facilitate easy comprehension, the manual is methodically divided into multiple comprehensive sections.

Key Features

- Foreword: Offers critical safety information and introductory details.

- General Information: Covers detailed machine specifications for the excavator.

- Structure and Function, Maintenance Standard:

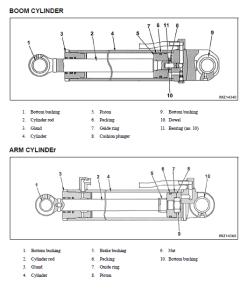

- Explains each component’s structure and function, which aids in troubleshooting.

- Describes maintenance standards, including disassembly and service criteria.

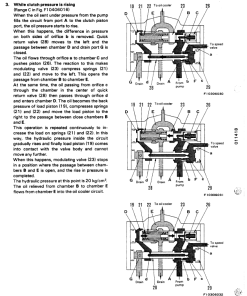

- Testing and Adjusting: Provides a standard value table and covers methods for testing and adjustment, including instrument usage and measuring techniques.

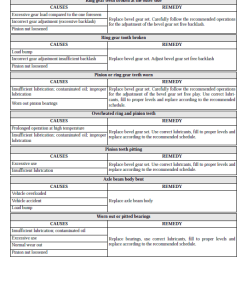

- Troubleshooting: Includes diagnostics for identifying and repairing failed parts, sorted by failure modes. Additional engine-related troubleshooting may be covered in the chassis and engine volumes.

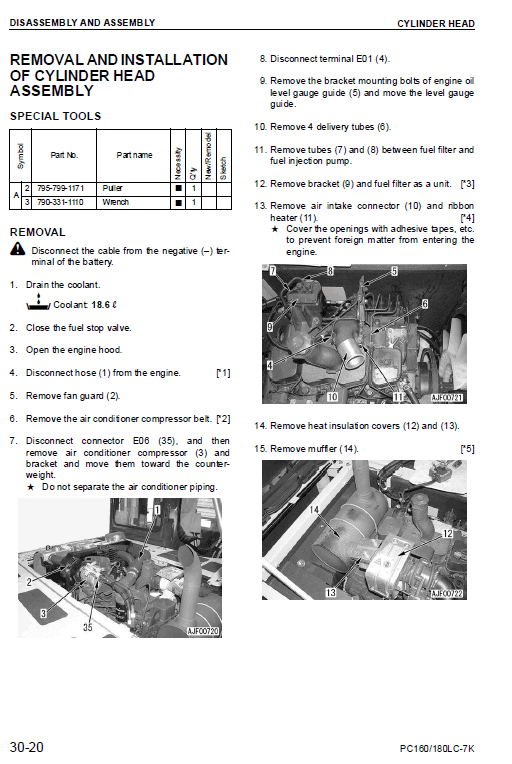

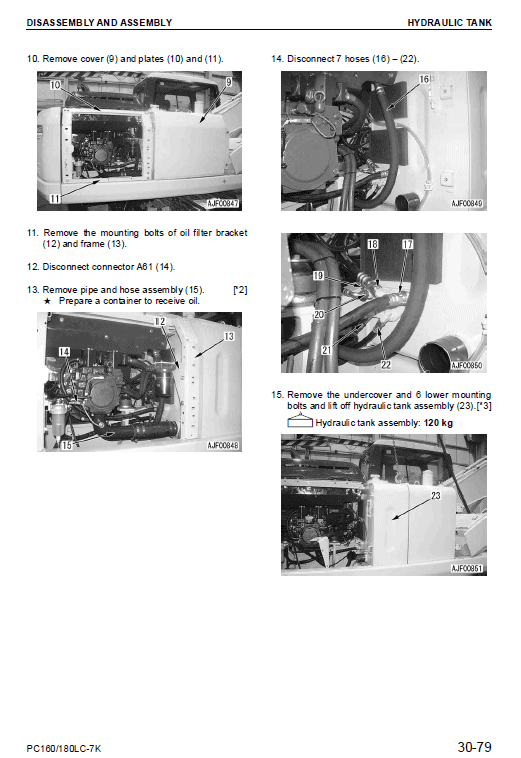

- Disassembly and Assembly: Details on using special tools, procedures, and precautions, including required tightening torques and material quantities.

- Others (Chassis/Engine Volume):

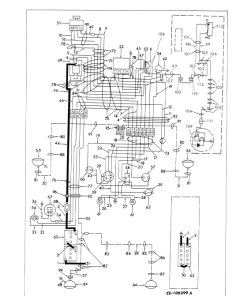

- Chassis: Contains hydraulic and electrical circuit diagrams.

- Engine: Describes parts repair, replacement, and reproduction methods.

Benefits

- Streamlined layout assists in the efficient location of necessary information.

- Enhances troubleshooting skills through detailed structural insights.

- Improves maintenance proficiency by providing clear standards and guidelines.

Usage Recommendations

- Regularly review the Foreword for updated safety measures and basic information.

- Refer to the section Structure and Function before attempting troubleshooting or repair work.

- Utilize the Testing and Adjusting section to ensure machine operations meet standard specifications.

- Follow the guidelines in Disassembly and Assembly for safe component handling and accurate reassembly.

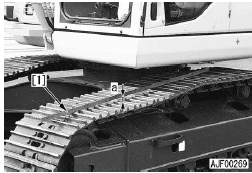

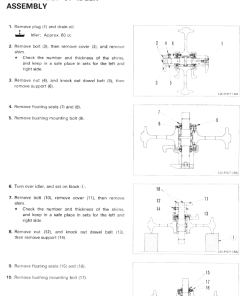

Inspection and Adjustment of Track Shoe Tension

- Move the machine forward over the track length at a low engine idle and come to a gradual stop.

- Place a straight bar (preferably an L beam) across the track shoe between the idler and the first carrier roller.

- Determine the maximum clearance between the bar and the track shoe. Standard clearance should be between 10 and 30 mm.

- If adjustment is necessary:

- Excess Tension: Loosen valve (1) cautiously to release grease. Do not loosen excessively as this can cause high-pressure grease expulsion.

- Insufficient Tension: Introduce grease through valve (1). If tension remains inadequate, gently move the machine back and forth to facilitate tension adjustment.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.00

Reviews

There are no reviews yet.