Comprehensive Shop Manual for Excavators

Product Overview

This shop manual serves as an essential guide, providing comprehensive technical information required for maintenance and service of excavators. Designed to ease understanding and enhance reliability, the manual is systematically divided into clearly defined sections.

Key Features

- Foreword: Contains critical safety instructions and basic operational information.

- General Specifications: Offers detailed specifications of the excavator’s machinery.

- Structure and Function, Maintenance Standards: Discusses the construction and roles of each component, serving as a foundation for effective troubleshooting and maintenance.

- Testing and Adjusting: Provides standard values and criteria essential for evaluating and fine-tuning machinery performance.

- Disassembly and Assembly: Guides on the use of special tools and the methodology for the assembly and disassembly of components, including precautionary measures.

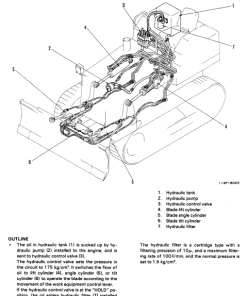

- Others: Includes additional details like hydraulic and electrical circuit diagrams for the chassis and procedures for the repair and replacement of engine parts.

Benefits

- Facilitates understanding of complex machinery through structured information.

- Serves as an invaluable reference during troubleshooting and repairs.

- Enhances service efficiency with detailed procedural guidelines.

Usage Recommendations

- Refer to the Testing and Adjusting section to determine standard machine values and make necessary adjustments.

- Use the Structure and Function section for component-level troubleshooting and understanding.

- Follow the detailed instructions in the Disassembly and Assembly section for secure handling of components during repairs.

- Consult Others section for comprehensive diagrams and parts information.

Detailed Procedures

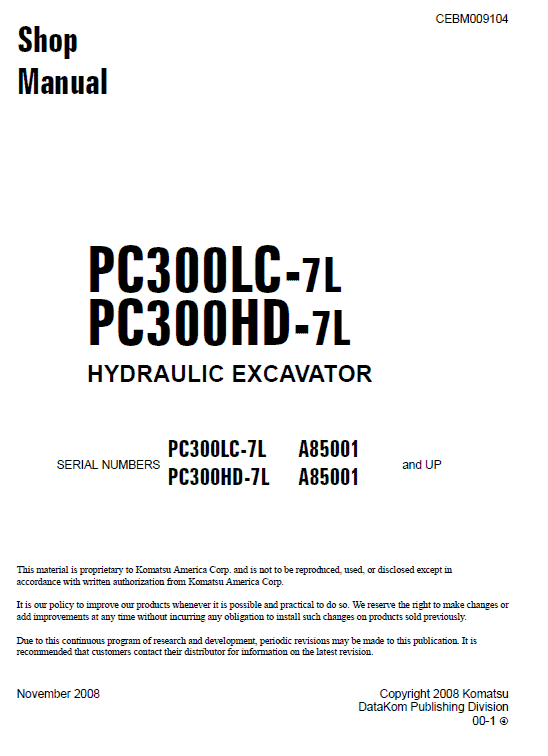

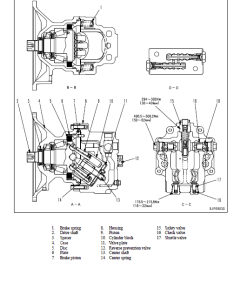

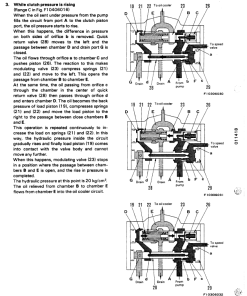

Structure and Function, Maintenance Standards

This section provides a thorough explanation of the excavator’s structure, function, and maintenance standards. Utilize this as reference material for diagnosing issues and to understand component interactions.

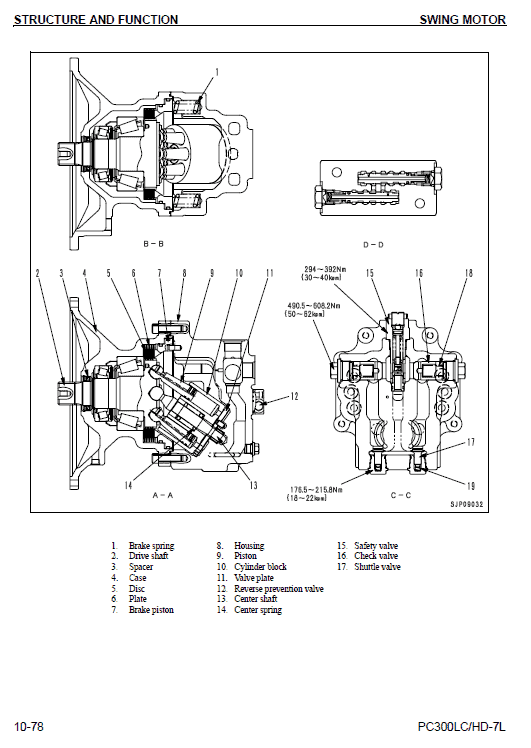

Testing and Adjusting

Here you will find measurements, procedures for testing and adjustments, and criteria to judge machine performance. Essential for maintaining operational efficiency, this section outlines proper testing and adjustment practices.

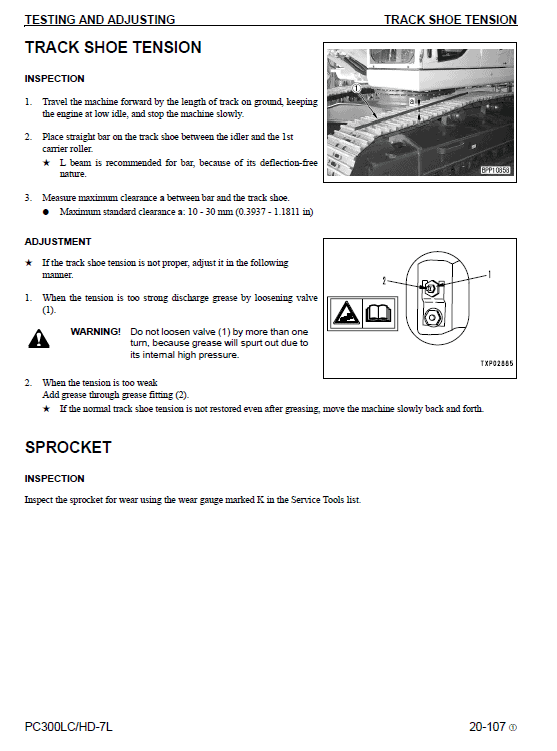

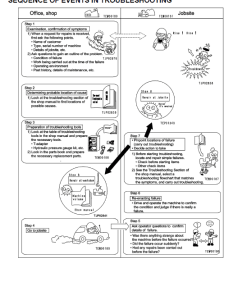

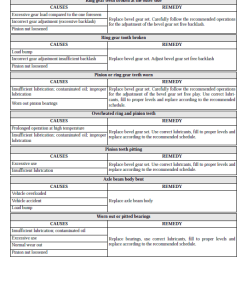

Troubleshooting

This segment details methods for identifying and repairing malfunctioning parts, organized by failure modes. For issues related to the engine, consult both the Chassis and Engine volumes.

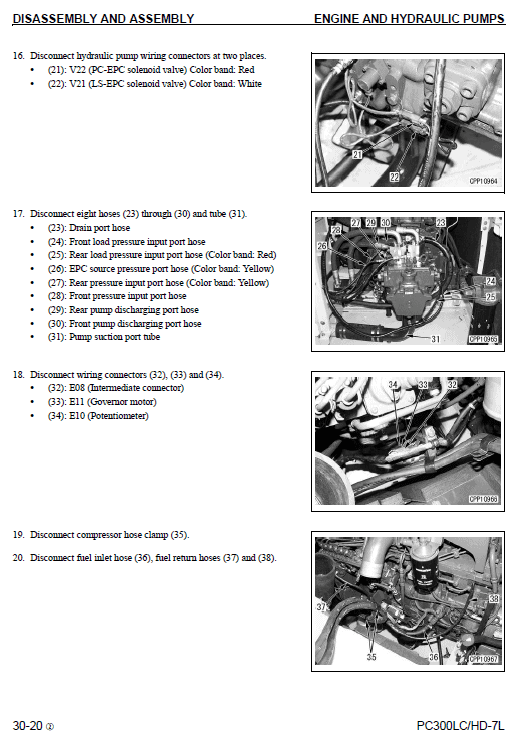

Disassembly and Assembly for Excavator

Includes instructions on using special tools for the removal and installation of excavator parts, emphasizing critical safety and procedural precautions.

Others (Chassis and Engine Volumes)

- Chassis Volume: Features hydraulic and electrical circuit diagrams crucial for repairs.

- Engine Volume: Offers methodologies for part reproduction, repair, and replacement.

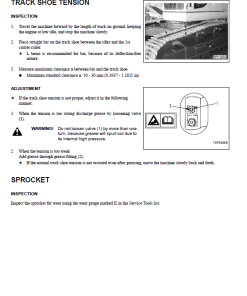

Sprocket Removal Instructions

- Remove the track shoe assembly. For details, refer to the section on TRACK SHOE, REMOVAL.

- Swing the work equipment 90 degrees, elevate the chassis with the work equipment, and position a block between the track frame and track shoe.

- Unfasten mount bolts and carefully lift off the sprocket.

Installation: Reinstall components in the reverse order of removal. Note: The sprocket weighs approximately 65 kg.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.